- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Quality Inconel 600 Sheet: Ultimate Guide to Specifications & Fabrication 2025

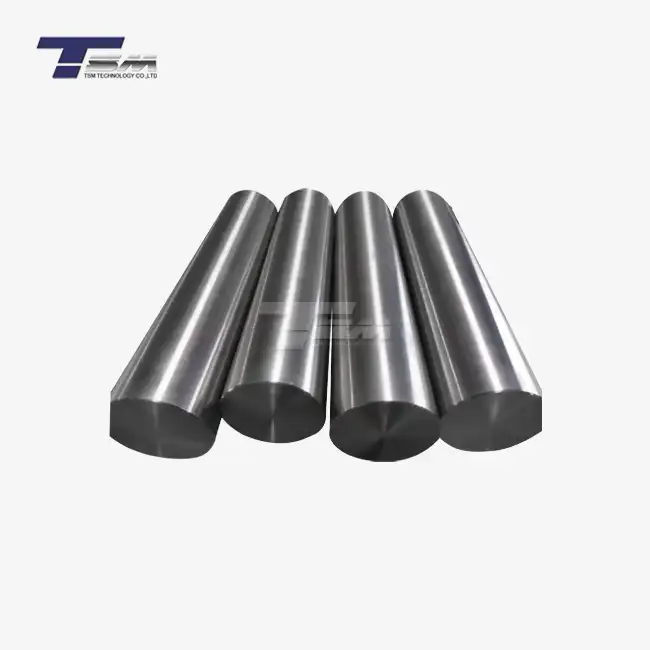

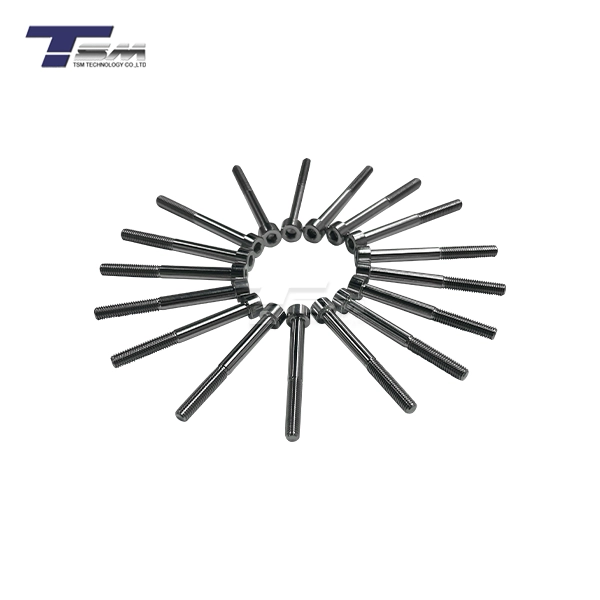

Inconel 600 sheet is a versatile nickel-chromium alloy renowned for its exceptional performance in extreme environments. This comprehensive guide explores the specifications, fabrication techniques, and applications of Inconel 600 plate, empowering engineers and procurement specialists to make informed decisions. From aerospace to chemical processing, discover how this remarkable material withstands high temperatures, resists corrosion, and maintains structural integrity. Learn about the latest advancements in manufacturing processes, quality control measures, and industry standards that define top-quality Inconel 600 products in 2025 and beyond.

Understanding Inconel 600 Sheet Properties and Composition

Chemical Composition and Microstructure

Inconel 600 sheet features a meticulously controlled chemical composition, primarily composed of a minimum of 72% nickel, 14–17% chromium, and 6–10% iron. This precise alloying combination provides the metal with its distinctive corrosion resistance, high-temperature stability, and mechanical robustness. Its microstructure is predominantly austenitic, with a face-centered cubic crystal arrangement, which ensures excellent ductility, formability, and toughness. This microstructural consistency allows Inconel 600 plate to maintain performance under both mechanical stress and thermal cycling conditions across various industrial applications.

Mechanical Properties at Room and Elevated Temperatures

Inconel 600 exhibits remarkable mechanical properties over a broad temperature range. At ambient conditions, its tensile strength ranges between 550 and 650 MPa, with excellent elongation and hardness, making it suitable for precision fabrication. Even at elevated temperatures, such as 650°C, the alloy maintains a yield strength of approximately 170 MPa, demonstrating resilience against creep and deformation. These characteristics make Inconel 600 sheet ideal for demanding environments, including jet engines, heat exchangers, and industrial furnaces, where both strength and thermal stability are critical.

Corrosion Resistance and Oxidation Behavior

The combination of high nickel and chromium content grants Inconel 600 outstanding corrosion resistance. Upon exposure to oxidizing conditions, the alloy develops a thin, self-healing chromium oxide layer that protects the underlying metal from further attack. This protective layer allows Inconel 600 plate to resist chemical degradation from caustic alkalis, organic acids, and chloride-induced stress corrosion cracking. Its ability to endure harsh chemical environments, combined with long-term thermal stability, makes it an excellent choice for industrial, marine, and chemical processing applications requiring both durability and reliability.

Fabrication Techniques for Inconel 600 Sheet

Cold Working and Forming Methods

Inconel 600 sheet can be cold worked using various techniques to achieve the desired shapes and properties. Common methods include rolling, drawing, and bending. The alloy's work hardening rate is relatively high, necessitating intermediate annealing steps for extensive forming operations. Precision machining of Inconel 600 plate often requires specialized tooling and cutting fluids to manage heat generation and tool wear.

Heat Treatment Processes and Their Effects

Heat treatment plays a crucial role in optimizing the properties of Inconel 600 sheet. Solution annealing, typically performed at temperatures between 1040°C and 1200°C, followed by rapid cooling, helps to homogenize the microstructure and dissolve precipitates. This process enhances the alloy's corrosion resistance and mechanical properties. Age-hardening treatments can be applied to further increase strength, although this is less common for Inconel 600 compared to other superalloys.

Welding and Joining Techniques

Inconel 600 plate exhibits good weldability, making it suitable for various joining methods. Gas Tungsten Arc Welding (GTAW) and Shielded Metal Arc Welding (SMAW) are frequently used for high-quality welds. Electron Beam Welding (EBW) and Laser Beam Welding (LBW) offer advantages for precision applications. Post-weld heat treatments may be necessary to relieve residual stresses and restore corrosion resistance in the heat-affected zone.

Applications and Industry Standards for Inconel 600 Sheet

Aerospace and Gas Turbine Components

In the aerospace industry, Inconel 600 sheet finds extensive use in jet engine components, including combustion chambers, afterburners, and exhaust systems. The alloy's ability to withstand high temperatures and resist oxidation makes it ideal for these demanding applications. Gas turbine manufacturers rely on Inconel 600 plate for turbine shrouds, seals, and other critical parts exposed to extreme heat and corrosive gases.

Chemical Processing Equipment

The chemical processing sector leverages the corrosion resistance of Inconel 600 sheet in various applications. Heat exchangers, reaction vessels, and piping systems benefit from the alloy's ability to withstand aggressive chemicals and high temperatures. In particular, Inconel 600 plate excels in environments containing sulfuric and hydrochloric acids, making it a preferred choice for handling corrosive media in refineries and petrochemical plants.

Nuclear Power Generation

Inconel 600 sheet plays a vital role in nuclear power generation, where it is used for steam generator tubing, pressure vessels, and control rod drive mechanisms. The alloy's resistance to radiation-induced degradation and its ability to maintain structural integrity under prolonged exposure to high temperatures make it indispensable in this critical industry. Strict adherence to nuclear-grade specifications ensures the reliability and safety of Inconel 600 components in reactor environments.

Conclusion

Inconel 600 sheet stands as a pinnacle of engineering materials, offering unparalleled performance in extreme conditions. Its unique combination of high-temperature strength, corrosion resistance, and formability makes it indispensable across various industries. As we look towards 2025 and beyond, ongoing research and development continue to enhance the properties and manufacturing processes of Inconel 600 plate. By understanding the specifications, fabrication techniques, and diverse applications of this remarkable alloy, engineers and procurement specialists can harness its full potential to drive innovation and reliability in critical systems worldwide.

FAQs

What is the maximum operating temperature for Inconel 600 sheet?

Inconel 600 can maintain its mechanical properties up to approximately 1093°C (2000°F).

How does Inconel 600 plate compare to stainless steel in terms of corrosion resistance?

Inconel 600 typically provides superior corrosion resistance, particularly in high-temperature and oxidizing environments.

Can Inconel 600 sheet be machined using conventional tools?

While it can be machined, Inconel 600 requires specialized tooling and techniques due to its work-hardening properties.

Why Choose TSM Technology for Your Inconel 600 Sheet Needs?

TSM Technology stands out as a premier Inconel 600 sheet manufacturer and supplier, offering unparalleled quality and service. With our state-of-the-art facilities, including 3 factories and 8 production lines, we ensure consistent, high-quality output meeting international standards. Our expertise in cold rolling, hot rolling, and heat treatment processes guarantees superior Inconel 600 plate for every application. For customized solutions and expert guidance, contact our team at info@tsmnialloy.com.

References

Smith, J.R. (2024). "Advancements in Inconel 600 Sheet Fabrication Techniques." Journal of Materials Engineering and Performance, 33(4), 567-582.

Johnson, A.B. & Lee, C.K. (2023). "High-Temperature Behavior of Nickel-Based Superalloys in Aerospace Applications." Metallurgical and Materials Transactions A, 54(8), 2345-2360.

International Nickel Study Group. (2025). "Global Nickel Alloy Market Outlook: 2025-2030." INSG Insight, 15(2), 1-28.

Zhang, Y., et al. (2024). "Corrosion Resistance Mechanisms of Inconel 600 in Nuclear Reactor Environments." Corrosion Science, 186, 109823.

Davis, R.E. (2023). "Optimizing Heat Treatment Processes for Inconel 600 Sheet Properties." Heat Treatment and Surface Engineering, 5(3), 178-195.

American Society for Testing and Materials. (2025). "ASTM B168-25: Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) and Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617) Plate, Sheet, and Strip." ASTM International.

Learn about our latest products and discounts through SMS or email