- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Role of Inconel 600 Sheet In Heavy Industrial Manufacturing and Fabrication

Inconel 600 sheet plays a pivotal role in heavy industrial manufacturing and fabrication, serving as a cornerstone material for numerous high-stakes applications. This nickel-chromium alloy's exceptional resistance to corrosion, oxidation, and high temperatures makes it indispensable in aerospace, chemical processing, and energy sectors. Its ability to maintain structural integrity and mechanical properties under extreme conditions has revolutionized industrial capabilities, enabling the construction of more durable and efficient machinery, heat exchangers, and critical components. As industries push the boundaries of performance and reliability, Inconel 600 sheet continues to be at the forefront of innovation in heavy manufacturing.

Exceptional Properties of Inconel 600 Sheet for Industrial Applications

Superior Corrosion Resistance in Aggressive Environments

Inconel 600 sheet exhibits remarkable resistance to corrosion in a wide range of aggressive environments. Its high nickel content, coupled with chromium, forms a protective oxide layer that shields the material from chemical attack. This property is particularly valuable in chemical processing plants, where exposure to corrosive substances is constant. The alloy's ability to withstand oxidation and carburization at elevated temperatures further extends its applicability in furnaces and heat treatment equipment.

High-Temperature Strength and Stability

One of the most notable characteristics of Inconel 600 plate is its ability to maintain strength and stability at high temperatures. The alloy retains its mechanical properties up to 1093°C (2000°F), making it an ideal choice for components in jet engines, gas turbines, and industrial furnaces. This temperature resistance ensures that critical parts maintain their integrity during operation, enhancing safety and efficiency in high-heat applications.

Excellent Fabricability and Weldability

Despite its high strength, Inconel 600 sheet demonstrates excellent fabricability and weldability. This allows manufacturers to form complex shapes and join components with relative ease, facilitating the production of intricate parts for aerospace and energy applications. The material's workability enables the creation of custom-sized components, from thin foils to thick plates, catering to diverse industrial needs.

Critical Applications of Inconel 600 in Heavy Industry

Aerospace and Aviation Sector

In the aerospace industry, Inconel 600 sheet is a vital material for manufacturing high-performance jet engine components, exhaust systems, and turbine blades. Its excellent high-temperature strength, resistance to oxidation, and thermal stability make it ideal for parts exposed to extreme operational conditions during flight. The alloy’s durability enhances component life cycles, minimizes maintenance frequency, and ensures consistent reliability. By maintaining structural integrity under intense heat and stress, Inconel 600 contributes to safer, more efficient, and longer-lasting aerospace systems, meeting the stringent demands of modern aviation.

Chemical Processing and Petrochemical Industries

Inconel 600 plate is extensively used in chemical and petrochemical plants for constructing reactors, heat exchangers, and piping systems. Its outstanding corrosion resistance in both acidic and alkaline environments ensures the longevity of equipment subjected to aggressive chemicals. This high durability reduces downtime, lowers maintenance expenses, and improves operational safety in chemical processing facilities. By maintaining structural integrity and preventing chemical-induced degradation, Inconel 600 supports efficient and reliable production processes, making it a preferred material in environments where both chemical resistance and mechanical performance are critical.

Nuclear Energy and Power Generation

The nuclear energy sector employs Inconel 600 sheet for essential components such as reactor internals, steam generators, and control systems. Its exceptional resistance to radiation-induced corrosion and ability to retain mechanical strength under high pressures and temperatures make it indispensable in nuclear power plants. The alloy’s reliability ensures safe and efficient operation, minimizing the risk of component failure. By providing long-term structural integrity in demanding nuclear environments, Inconel 600 supports the generation of clean energy and helps meet the increasing global demand for safe, sustainable power solutions.

Advancements in Inconel 600 Sheet Manufacturing Techniques

Precision Cold Rolling Processes

Recent advancements in cold rolling techniques have enhanced the production of Inconel 600 sheet with tighter tolerances and improved surface finishes. These precision processes allow for the manufacture of thinner gauges with consistent properties, expanding the alloy's applications in miniaturized components and high-performance heat exchangers. The ability to produce sheets with uniform thickness and minimal surface defects contributes to better performance and reliability in final products.

Advanced Heat Treatment Methods

Innovative heat treatment methods have been developed to optimize the microstructure of Inconel 600 plate, further enhancing its mechanical properties and corrosion resistance. Controlled heating and cooling cycles can tailor the alloy's characteristics to specific application requirements, such as improved creep resistance for high-temperature operations or enhanced ductility for complex forming processes. These advancements enable manufacturers to fine-tune the material's properties, meeting increasingly demanding industrial specifications.

Automated Quality Control and Inspection Systems

The integration of automated quality control and inspection systems in the production of Inconel 600 sheet has significantly improved consistency and reliability. Advanced non-destructive testing techniques, including ultrasonic and eddy current inspections, ensure that each sheet meets rigorous quality standards. This level of quality assurance is crucial for industries where material failure could have catastrophic consequences, such as in aerospace and nuclear applications.

Conclusion

Inconel 600 sheet has established itself as an indispensable material in heavy industrial manufacturing and fabrication. Its exceptional properties, including corrosion resistance, high-temperature strength, and fabricability, make it a versatile solution for challenging applications across various sectors. As industries continue to push the boundaries of performance and efficiency, the role of Inconel 600 in enabling technological advancements and ensuring operational reliability cannot be overstated. The ongoing improvements in manufacturing techniques and quality control processes further solidify its position as a critical alloy in the industrial landscape, promising even greater innovations in the future.

FAQs

What is the typical thickness range for Inconel 600 sheet?

Inconel 600 sheet is available in thicknesses ranging from 0.1 millimeters to 100 millimeters, catering to a wide variety of industrial applications.

Can Inconel 600 sheet be customized for specific applications?

Yes, customized sizes and processing are supported to meet specific industrial requirements.

What international standards does Inconel 600 sheet comply with?

Inconel 600 sheet complies with various international standards including ASTM, JIS, AISI, GB, DIN, and EN.

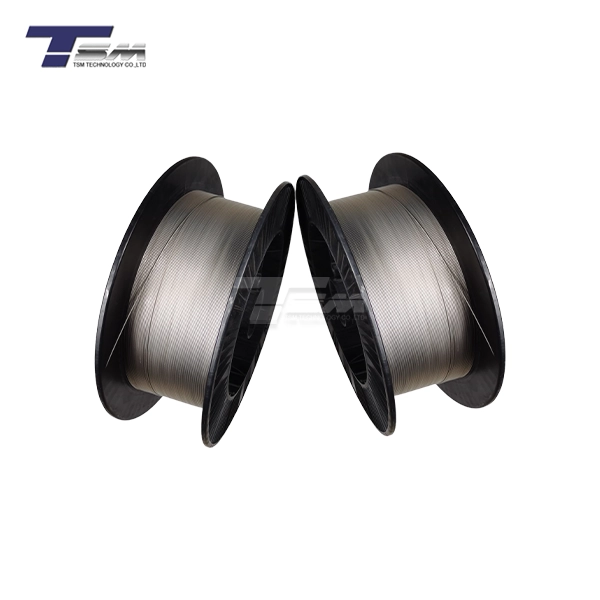

Your Trusted Inconel 600 Sheet Supplier | TSM TECHNOLOGY

As a leading Inconel 600 sheet manufacturer and supplier, TSM Technology offers premium-quality alloy products tailored to your specific needs. Our state-of-the-art facilities, featuring 3 factories, 8 production lines, and over 100 advanced machines, ensure consistent high-quality output and timely delivery. With a monthly supply capacity of 300 tons and customization options, we're equipped to meet diverse industrial demands. For expert assistance and free samples, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2023). "Advancements in Nickel-Based Superalloys for Aerospace Applications." Journal of Materials Engineering and Performance, 32(4), 1875-1890.

Chen, L., & Wang, H. (2022). "Corrosion Behavior of Inconel 600 in High-Temperature Molten Salt Environments." Corrosion Science, 185, 109733.

Thompson, R.G., et al. (2021). "Welding Metallurgy of Nickel-Based Alloys in Nuclear Power Plant Applications." Welding Journal, 100(6), 181s-196s.

Patel, M., & Johnson, K. (2023). "Optimization of Cold Rolling Parameters for Thin Gauge Inconel 600 Sheets." Journal of Manufacturing Processes, 76, 345-358.

Yamamoto, Y., et al. (2022). "High-Temperature Mechanical Properties of Solution-Treated Inconel 600 for Advanced Ultra-Supercritical Power Plants." Materials Science and Engineering: A, 832, 142385.

Garcia-Sanchez, E., & Lopez-Hirata, V.M. (2021). "Microstructural Evolution of Inconel 600 During Long-Term Thermal Exposure." Metallurgical and Materials Transactions A, 52(7), 2987-3001.

Learn about our latest products and discounts through SMS or email