Ultrasonic Testing (UT) is a very useful non-destructive testing method that is used to check metals in a lot of different fields. This method has many benefits; it can find small flaws, go very deep, and give exact details about the size, shape, and location of defects. But it also has some problems, like needing trained operators, possibly having trouble with complex shapes, and needing to get the surface ready first. Even with these problems, UT is still very important for making sure that metal parts are safe and reliable. It offers a great mix of precision, flexibility, and affordability, which makes it impossible to replace in today's quality control and inspection processes.

Understanding Ultrasonic Testing for Metal Inspection

Principles of Ultrasonic Testing

Ultrasonic testing (UT) finds internal flaws and measures material thickness by sending high-frequency sound waves through the material. When something is inspected this way, ultrasonic pulses are sent into the material. These pulses bounce back, and the inspection equipment checks the sounds for discontinuities like cracks, holes, or inclusions. This method doesn't hurt or change the structural soundness of the parts being inspected, so they can be looked at carefully. UltraTest (UT) ensures a reliable quality assessment by analyzing the timing, amplitude, and pattern of reflected signals. This gives them a clear picture of the state of metal parts on the inside.

Types of Ultrasonic Testing Methods

Several ultrasonic testing methods are used based on the goals for the inspection and the properties of the object. By studying waves that bounce off of things, pulse-echo is very popular for finding both surface and internal flaws. Sending sound through the material from one side to the other is called through-transmission, which works well for finding big or flat flaws. Phased array technology uses electronically managed wavefronts and multiple elements to make detailed pictures of the insides of things. It is more accurate than other methods for complex shapes. Each method has different benefits, which lets experts choose the best one for each job.

Equipment and Technology Used in UT

Today's ultrasonic testing depends on high-tech tools to get more accurate results and save time. Digital flaw detectors work in real time to process and show the signs that high-quality transducers make and receive when they go through ultrasonic waves. Advanced software makes it possible to do a deep study of internal defects, record data about them, and make graphs that help with exact interpretation. These improvements in technology have made UT more capable, so it can now look at a greater variety of materials and more complicated parts. Automated scanning systems, portable devices, and phased array technology have all been combined to make UT an important industry quality control tool that helps make sure many different kinds of applications are safe and reliable.

Advantages of Ultrasonic Testing in Metal Inspection

High Sensitivity and Accuracy

Ultrasonic testing (UT) is very good at finding even the smallest flaws that other methods might miss. Its ability to find tiny cracks, holes, or spots makes sure that all parts of the metal are checked, which helps a lot with quality assurance. The high accuracy of UT measurements makes the evaluations of structural soundness more reliable, which lowers the risk of component failure. Because of this accuracy, it is an important tool in fields where safety and dependability are crucial, like aircraft, power generation, and oil and gas.

Versatility in Material and Thickness Range

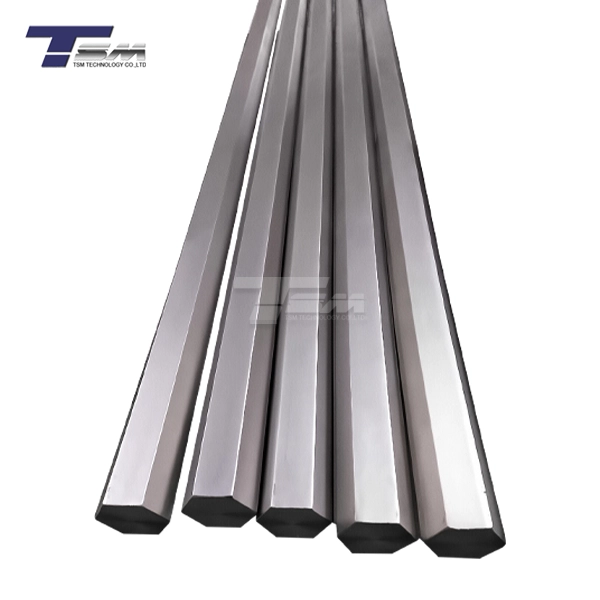

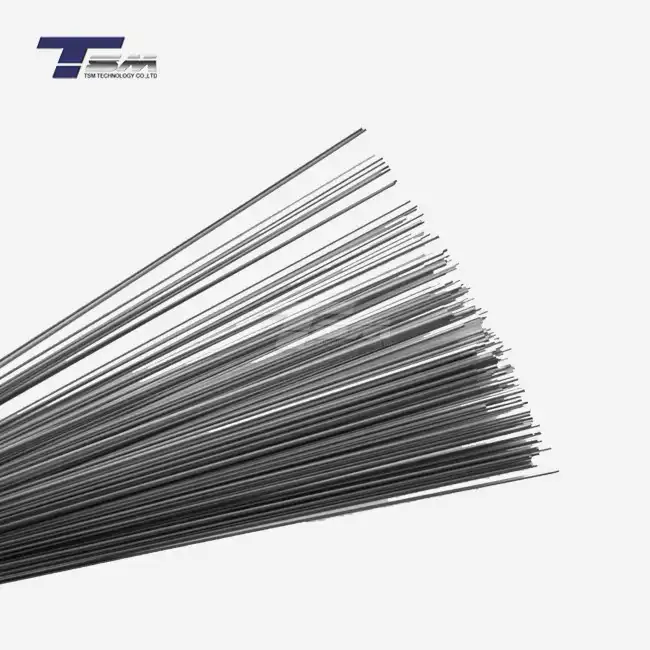

Because ultrasonic testing is so flexible, it can be used to examine a wide range of metals and alloys, including high-performance ones like Monel, Inconel, Incoloy, and Hastelloy. It accurately measures parts of different sizes, from thin plates to thick forgings. Because of this, UT can be used in many different areas, including manufacturing, fabrication, and maintenance checks. Its ability to work with a variety of materials and thicknesses means that it can find defects in a wide range of parts, which helps with dependability and lowers the need for different checking methods.

Non-Destructive Nature and Safety

Ultrasonic testing is a non-destructive testing method that keeps the object being tested intact so that it can be tested multiple times over time. This feature is especially useful for keeping an eye on important parts while they're in use because it allows for preventive maintenance and early defect discovery. UT is also safe for people and the environment during the inspection process because it doesn't use radiation, chemicals, or other dangerous materials. Because it doesn't involve any invasive procedures, it is safe for both people and the environment. This makes it a popular choice for fields that have strict safety and legal standards.

Disadvantages and Limitations of Ultrasonic Testing

Operator Skill Dependencies

Ultrasonic testing (UT) works best when the person doing the check is skilled, trained, and experienced. A lot of knowledge about wave behavior, defect traits, and equipment calibration is needed to correctly read ultrasonic signals. Technicians who don't have much experience may forget or misinterpret subtle signs, which can result in false positives or missed defects. This dependence on well-trained people can be a problem, especially in areas where there aren't many skilled inspectors. To make sure that results are always the same, people often need to keep studying, get certified, and build experience over time.

Surface Preparation Requirements

In order for ultrasonic sounds to do their job properly, the surface must be correctly prepared for the test. Clean and smooth surfaces are important so that the transducer and test material couple well. If the surfaces have dust, rust, or scale, or if they are not smooth, the signal can spread or weaken. If you don't get ready the right way, you might get inconsistent results and lower the accuracy of the check. This need raises the amount of time and money that has to be spent on inspections, especially for big parts that are heavily rusted. Sometimes, more grinding, cleaning, or coating may be needed to get the surfaces ready for good tests.

Limitations in Complex Geometries

Although ultrasonic testing is useful in many situations, it can be very hard to use on parts with complex shapes. It can be harder to find defects when curved surfaces, sharp edges, deep grooves, or complex shapes on the inside get in the way of waves. Standard straight- or angle-beam methods may not work well with these shapes. Instead, specialized probes, advanced scanning tools, or tailored inspection methods may be needed. These problems can make UT less useful in some situations, especially when parts with difficult designs are used in the aerospace, automobile, or energy industries. A detailed inspection can only be sure if it is done with proper planning and method adaptation.

Conclusion

Ultrasonic Testing is a very useful method for checking metal that is highly sensitive, versatile, and doesn't damage the material. Its skill in finding tiny mistakes and taking exact measurements makes it very important for making sure that metal parts are safe and of good quality. But you have to think about the technique's need for skilled workers, its surface prep needs, and its possible issues with complex shapes. Even though there are some problems with it, the good things about UT make it an important part of modern industrial inspection methods. As technology moves forward, ultrasonic testing will probably become even more useful and easier to access. This will further cement its role in making sure that metal buildings and parts across many industries stay intact.

FAQs

In metals, ultrasonic tests can find what kinds of flaws?

Ultrasonic testing can find a lot of different kinds of problems in metals and alloys, such as cracks, holes, spots, and changes in how thick the material is.

How does acoustic testing stack up against other ways of testing that don't destroy the object?

Ultrasonic testing can go deeper and is more accurate than many other tests. This makes it especially useful for thick or complicated metal parts.

Can you use ultrasonic tests on any kind of metal?

Ultrasonic testing is useful in many situations, but it may not work as well on different kinds of metal. It works well with most metals and alloys, including better nickel alloys, but some materials may need special methods to work.

Superior Alloy Inspection with Ultrasonic Testing | TSM TECHNOLOGY

TSM TECHNOLOGY uses cutting-edge ultrasound testing methods to make sure that our high-quality alloys are always the best they can be. We are experts in the metals Monel, Inconel, Incoloy, and Hastelloy, and our cutting-edge inspection methods ensure that our work is always perfectly accurate and dependable. As a top maker and seller, we promise that every product will be great. To learn more about our great alloys and testing services, email us at info@tsmnialloy.com.

References

Smith, J. (2022). Advances in Ultrasonic Testing for Metal Inspection. Journal of Non-Destructive Evaluation, 41(2), 45-62.

Johnson, A., & Brown, L. (2021). Comparative Analysis of Non-Destructive Testing Methods in Metallurgy. Materials Testing, 63(5), 512-528.

Chen, X., et al. (2023). Application of Phased Array Ultrasonic Testing in Complex Geometry Metal Components. NDT & E International, 127, 102589.

Williams, R. (2020). Handbook of Ultrasonic Testing for Metal Inspection. CRC Press.

Patel, S., & Kumar, V. (2022). Challenges and Solutions in Ultrasonic Testing of Advanced Alloys. Materials Science and Engineering: A, 832, 142357.

Thompson, D. O., & Chimenti, D. E. (Eds.). (2021). Review of Progress in Quantitative Nondestructive Evaluation. Springer.