- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding Nickel Alloys - Monel® and Hastelloy®

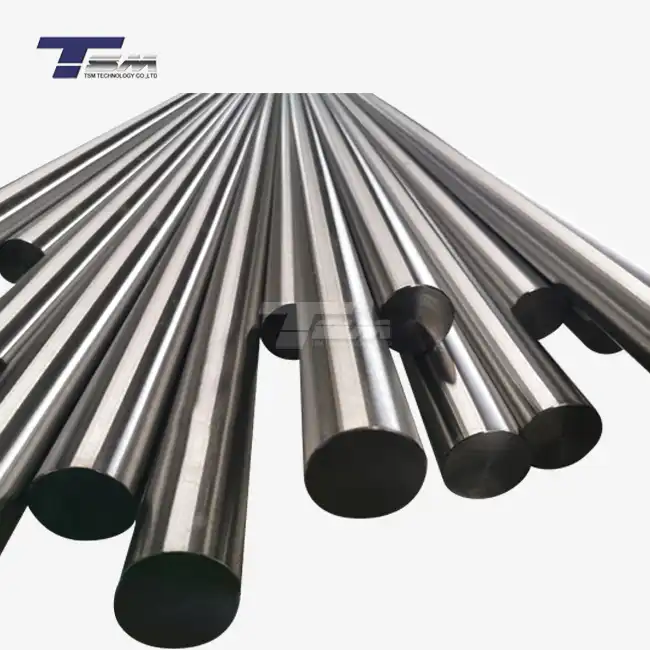

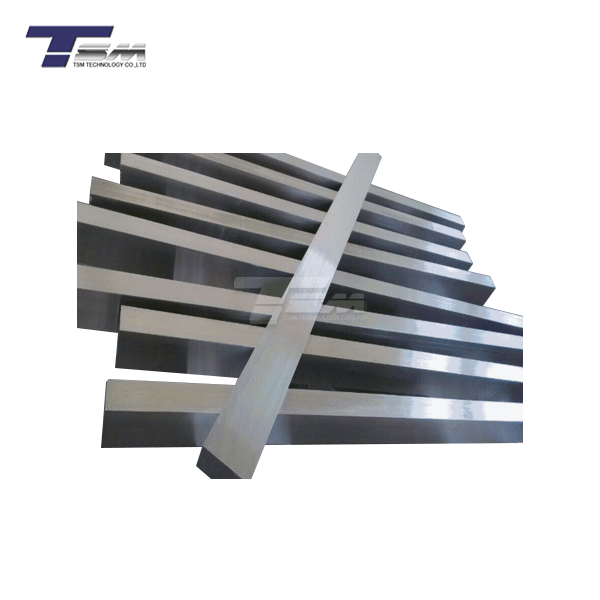

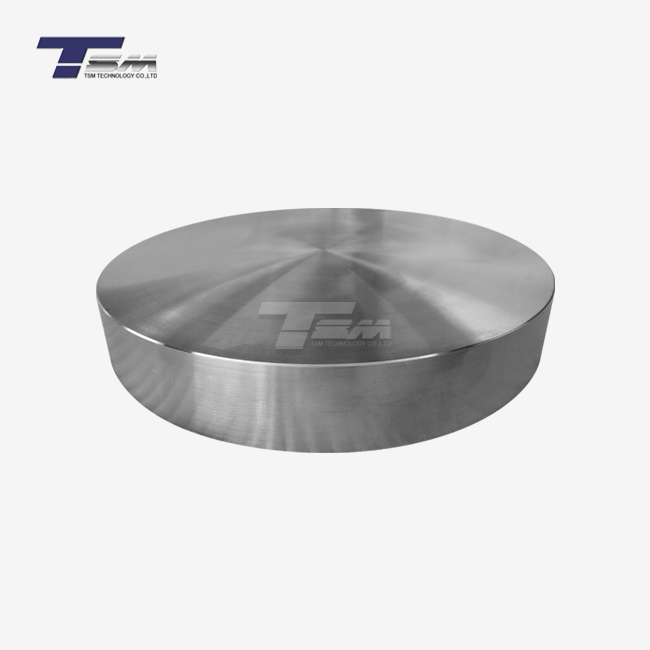

Nickel alloys have revolutionized the world of metallurgy, offering exceptional strength, corrosion resistance, and performance in extreme environments. Among these, Monel® and Hastelloy® stand out as two of the most renowned and versatile nickel-based alloys. These materials have found widespread applications across various industries, from aerospace and chemical processing to marine engineering and oil & gas. In this comprehensive guide, we'll delve into the unique properties, compositions, and applications of Monel alloys and Hastelloy alloys, exploring why they've become indispensable in modern engineering and manufacturing.

The Remarkable Properties of Monel Alloys

Composition and Characteristics

Monel alloys are primarily composed of nickel and copper, with small amounts of iron, manganese, and other elements. This unique composition results in a material that combines the best properties of both nickel and copper. Monel alloys exhibit exceptional corrosion resistance, particularly in seawater and reducing environments. They also maintain their strength and toughness across a wide range of temperatures, making them suitable for cryogenic applications as well as high-temperature environments.

Types of Monel Alloys

Monel alloys come in various grades, each engineered for distinct industrial needs. Monel 400 is widely used in marine and chemical processing thanks to its robust corrosion resistance. Monel K-500 builds on this by adding aluminum and titanium, enabling higher strength through heat treatment. Monel R-405 incorporates sulfur to enhance machinability, making it suitable for automatic screw machines. Monel 404, with its low magnetic permeability, is ideal for precision instruments and sensitive electronic components.

Applications of Monel Alloys

Monel alloys are valued across multiple industries for their exceptional durability and corrosion resistance. In marine engineering, they're ideal for propeller shafts, seawater valves, and pumps, enduring harsh saltwater environments. The chemical industry relies on Monel for reactors, piping, and heat exchangers exposed to aggressive chemicals. In aerospace, it's used in fuel lines, exhaust systems, and engine components due to its high-temperature strength. The food industry employs Monel in sanitary piping and processing tanks, as it resists corrosion while maintaining product purity and hygiene.

Exploring the Versatility of Hastelloy Alloys

Composition and Key Features

Hastelloy alloys are a family of nickel-chromium-molybdenum superalloys known for their exceptional corrosion resistance in highly aggressive environments. The addition of chromium and molybdenum to the nickel base results in alloys that can withstand extreme temperatures and highly corrosive media. Hastelloy alloys also exhibit excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

Varieties of Hastelloy Alloys

The Hastelloy family features multiple grades, each engineered to perform under unique and demanding conditions. Hastelloy C-276 is widely used in chemical processing due to its broad resistance to strong oxidizers and reducing agents. Hastelloy X is ideal for high-temperature applications, such as in jet engines and industrial furnaces, thanks to its excellent strength and oxidation resistance. Hastelloy B-3 handles highly reducing environments, including hydrochloric acid. Hastelloy G-30 is particularly effective in environments with strong phosphoric and nitric acids, making it suitable for fertilizer and chemical production.

Industrial Applications of Hastelloy

Hastelloy alloys are indispensable in industries that demand exceptional corrosion resistance and durability. In chemical processing plants, they are commonly used for vessels, condensers, and piping that must withstand aggressive chemicals and extreme temperatures. The oil and gas sector employs Hastelloy in subsea equipment and sour gas handling systems due to its resilience in high-pressure, corrosive environments. Environmental systems, such as flue gas scrubbers, benefit from Hastelloy's stability against acidic exhaust gases. Additionally, in the pharmaceutical industry, Hastelloy ensures contamination-free processing of sensitive drugs and chemicals.

Comparative Analysis: Monel vs. Hastelloy

Corrosion Resistance

Although Monel and Hastelloy alloys both offer outstanding corrosion resistance, their performance varies based on the environment. Monel, with its high nickel and copper content, is highly effective in reducing environments like seawater and brine, making it a popular choice in marine engineering. Hastelloy, composed of nickel, molybdenum, and chromium, offers enhanced protection in oxidizing conditions and aggressive chemical processes, such as those involving hot acids, chlorides, and oxidizing salts. This makes Hastelloy the preferred material in chemical plants and harsh industrial settings.

Mechanical Properties

Monel alloys typically provide greater strength and hardness than pure nickel while still offering good ductility and toughness, making them suitable for demanding mechanical applications. Hastelloy alloys, especially grades like C-22 and B-3, can reach even higher strength levels, particularly when precipitation-hardened, without compromising flexibility. Both alloys perform well under high temperatures, but Hastelloy generally surpasses Monel in thermal stability and resistance, making it more suitable for extreme heat environments in chemical and aerospace industries.

Cost and Availability

The cost of these alloys can vary significantly based on market conditions and specific grades. Generally, Monel alloys tend to be more cost-effective due to their simpler composition and wider availability. Hastelloy alloys, with their more complex compositions and specialized applications, often come at a premium. However, the long-term cost benefits in terms of durability and reduced maintenance often justify the initial investment in either alloy system for appropriate applications.

Conclusion

Understanding the unique properties and applications of Monel and Hastelloy alloys is crucial for engineers and manufacturers working in demanding industries. These nickel-based superalloys offer unparalleled performance in corrosive and high-temperature environments, making them indispensable in modern engineering. Whether it's the seawater resistance of Monel or the chemical processing capabilities of Hastelloy, these alloys continue to push the boundaries of material science, enabling innovations across various sectors. As technology advances, the development and refinement of these alloys will undoubtedly play a pivotal role in shaping the future of industrial materials.

Contact Us

For more information about our superior nickel alloy products, including Monel and Hastelloy, please contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect alloy solution for your specific needs.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International.

Rebak, R.B. (2011). Nickel Alloys for Corrosive Environments. The NACE International Book of Standards.

Donachie, M.J., & Donachie, S.J. (2002). Superalloys: A Technical Guide. ASM International.

Revie, R.W., & Uhlig, H.H. (2008). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. John Wiley & Sons.

Crook, P. (2005). Corrosion Characteristics of Nickel Alloys. Materials Performance, 44(9), 36-40.

Klarstrom, D.L., Crook, P., & Wu, J.B. (2004). Metallography and Microstructures of Nickel and Nickel Alloys. ASM Handbook, Volume 9: Metallography and Microstructures.

Learn about our latest products and discounts through SMS or email