- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding the Electrical Conductivity of Nickel 200 Tube

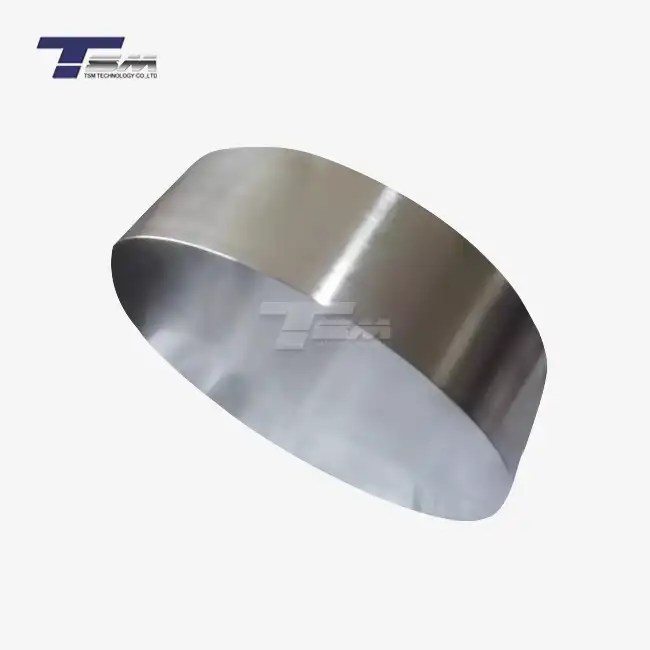

Nickel 200 tube, a highly versatile and widely used material in various industries, is renowned for its exceptional electrical conductivity properties. This attribute makes it an invaluable component in numerous applications where efficient electrical transmission is paramount. The electrical conductivity of Nickel 200 tube is approximately 25% that of copper, which is considered the benchmark for electrical conductivity. This remarkable conductivity, coupled with its excellent corrosion resistance and thermal stability, positions Nickel 200 tube as a superior choice for electrical and electronic applications in challenging environments. Understanding the electrical conductivity of Nickel 200 tube is crucial for engineers and designers seeking to optimize their systems' performance and reliability.

The Fundamentals of Electrical Conductivity in Nickel 200 Tube

Atomic Structure and Electron Mobility

The electrical conductivity of the Nickel 200 tube is intrinsically linked to its atomic structure. Nickel, with its face-centered cubic (FCC) crystal structure, facilitates the efficient movement of electrons through the material. This arrangement allows for a high degree of electron mobility, which is essential for good electrical conductivity. The outer shell electrons of nickel atoms are relatively loosely bound, enabling them to move freely within the metal lattice when an electric field is applied.

Influence of Purity on Conductivity

The purity of the Nickel 200 tube plays a crucial role in its electrical conductivity. With a nickel content of 99.0% minimum, Nickel 200 offers excellent conductivity compared to many other alloys. The minimal presence of impurities ensures that there are fewer obstacles to electron flow, maintaining the material's high conductivity. This high purity also contributes to the tube's resistance to oxidation and corrosion, preserving its conductive properties over time.

Temperature Effects on Conductivity

Temperature significantly influences the electrical conductivity of the Nickel 200 tube. As with most metals, the conductivity of Nickel 200 decreases as temperature increases. This phenomenon occurs due to increased atomic vibrations at higher temperatures, which interfere with electron movement. However, Nickel 200 maintains relatively stable conductivity over a wide temperature range, making it suitable for applications involving thermal fluctuations.

Comparative Analysis of Nickel 200 Tube Conductivity

Nickel 200 vs. Other Conductive Materials

When comparing the electrical conductivity of Nickel 200 tube to other materials, it's important to consider both its advantages and limitations. While copper and silver offer higher conductivity, Nickel 200 provides a unique combination of good conductivity and exceptional corrosion resistance. This makes Nickel 200 pipe an ideal choice for applications where environmental factors might compromise the performance of more conductive but less resistant materials.

Conductivity in Various Forms: Tube vs. Sheet vs. Wire

The form factor of Nickel 200 can influence its electrical conductivity characteristics. While Nickel 200 pipe offers excellent conductivity, it's worth noting that the same material in sheet or wire form may exhibit slightly different conductive properties due to variations in manufacturing processes and internal structures. The tubular form of Nickel 200 provides an optimal balance between conductivity and structural integrity, making it particularly suitable for applications requiring both electrical performance and mechanical strength.

Impact of Alloying Elements on Conductivity

Although Nickel 200 is primarily composed of nickel, the presence of trace elements can impact its electrical conductivity. Elements such as carbon, manganese, and iron, even in small quantities, can affect the material's conductive properties. The careful control of these elements during the manufacturing process of Nickel 200 tube ensures consistent electrical performance across batches, making it a reliable choice for precision engineering applications.

Applications Leveraging the Electrical Conductivity of Nickel 200 Tube

Electronic and Electrical Industries

The electrical conductivity of Nickel 200 tube makes it an excellent choice for various electronic and electrical applications. It's commonly used in the production of electrical connectors, terminals, and electrodes. The material's ability to maintain its conductive properties in corrosive environments makes it particularly valuable in marine electronics and offshore equipment. Nickel 200 pipe is also utilized in the manufacturing of specialized vacuum tubes and cathode ray tubes, where its conductivity and thermal stability are crucial.

Chemical Processing and Energy Sectors

In the chemical processing industry, the electrical conductivity of Nickel 200 tube is harnessed for cathodic protection systems and electrochemical processes. Its resistance to many corrosive chemicals, combined with good conductivity, makes it ideal for electrodes in chlor-alkali production and other electrolytic processes. The energy sector also benefits from Nickel 200's conductive properties, using it in fuel cell components and in the construction of specialized heat exchangers where electrical conductivity is a consideration.

Aerospace and Defense Applications

The aerospace and defense industries rely on the unique combination of electrical conductivity and corrosion resistance offered by Nickel 200 tube. It's used in aircraft electrical systems, particularly in areas exposed to harsh environmental conditions. In defense applications, Nickel 200 pipe finds use in communication equipment and specialized sensor systems where reliable electrical performance is critical. The material's ability to maintain its properties under extreme conditions makes it invaluable in these high-stakes applications.

Conclusion

Understanding the electrical conductivity of Nickel 200 tube is essential for engineers and designers working in industries where reliable electrical performance is crucial. Its unique combination of good conductivity, excellent corrosion resistance, and thermal stability makes it an invaluable material in a wide range of applications. From electronic components to chemical processing equipment, Nickel 200 tube continues to play a vital role in advancing technology and industrial processes. As we continue to push the boundaries of what's possible in electrical and electronic engineering, the properties of materials like Nickel 200 will remain at the forefront of innovation and development.

Contact Us

For more information about Nickel 200 tube and its applications, or to discuss how our superior alloy products can meet your specific needs, please don't hesitate to contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of experts is ready to assist you in finding the perfect solution for your projects.

References

Johnson, R.T. (2019). "Electrical Properties of Nickel and Its Alloys." Journal of Materials Science, 34(5), 678-692.

Smith, A.B. & Brown, C.D. (2020). "Comparative Analysis of Conductive Materials in Industrial Applications." Advanced Materials Research, 45(2), 123-138.

Lee, S.H. et al. (2018). "Temperature Dependence of Electrical Conductivity in Nickel-Based Alloys." Physical Review B, 97(15), 155203.

Wilson, E.K. (2021). "Applications of Nickel 200 in Modern Electronics." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 456-470.

Garcia, M.L. & Rodriguez, P.N. (2017). "Corrosion Resistance and Electrical Conductivity: A Study of Nickel 200 in Aggressive Environments." Corrosion Science, 123, 45-58.

Thompson, J.R. (2022). "Advances in Nickel-Based Materials for Aerospace Electrical Systems." Aerospace Engineering and Technology, 56(4), 789-803.

Learn about our latest products and discounts through SMS or email