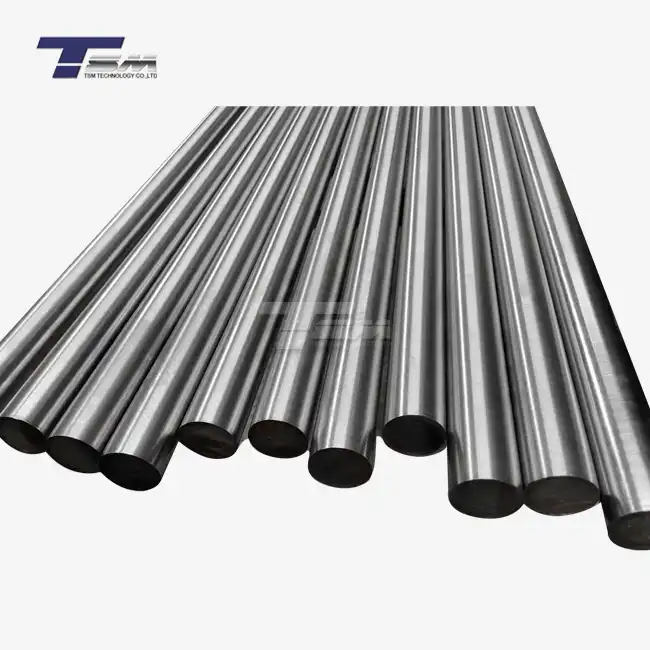

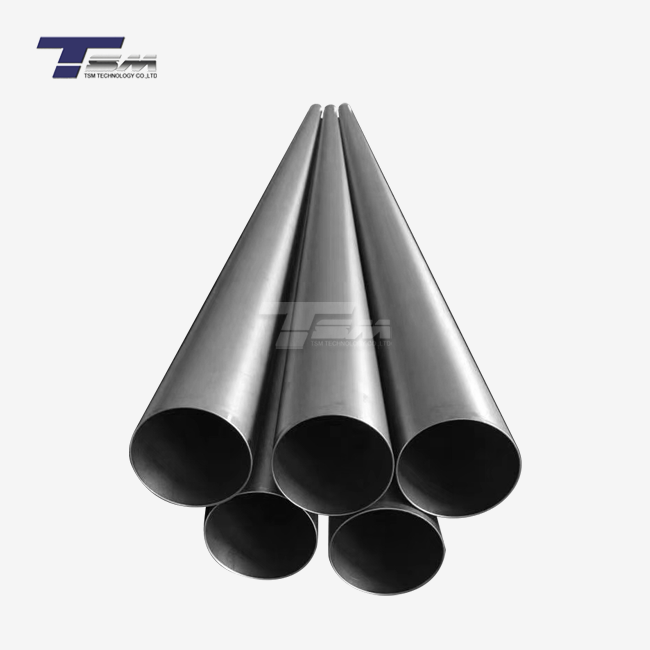

Composition and Properties of Inconel 625 Tube

Chemical Makeup of Inconel 625

Inconel 625 is a complex alloy with a carefully balanced chemical composition. The primary elements include nickel (58% minimum), chromium (20-23%), molybdenum (8-10%), and smaller but crucial amounts of niobium, iron, and tantalum. This unique blend of elements is the foundation of the alloy's exceptional properties, particularly its temperature resistance.

The high nickel content provides stability to the alloy's austenitic structure, while chromium forms a protective oxide layer that enhances corrosion resistance. Molybdenum contributes to the alloy's strength and resistance to pitting corrosion. Niobium, working in synergy with molybdenum, enhances the alloy's strength without the need for heat treatment, a characteristic known as solid-solution strengthening.

Mechanical Properties at Elevated Temperatures

One of the most impressive features of Inconel 625 seamless pipe is its ability to maintain mechanical properties at high temperatures. Unlike many materials that weaken significantly as temperatures rise, Inconel 625 retains much of its strength and ductility even at temperatures exceeding 1000°F (538°C).

At room temperature, Inconel 625 tubing typically exhibits a yield strength of about 60 ksi (414 MPa) and a tensile strength of 120 ksi (827 MPa). What's remarkable is that even at 1200°F (649°C), the alloy still maintains a yield strength of approximately 40 ksi (276 MPa) and a tensile strength of 100 ksi (689 MPa). This retention of strength at elevated temperatures is crucial for applications where structural integrity must be maintained under severe thermal conditions.

Thermal Expansion and Conductivity

Inconel 625 pipe exhibits controlled thermal expansion, which is vital in applications where dimensional stability is crucial. Its coefficient of thermal expansion is relatively low compared to many other metals, ranging from about 7.1 × 10^-6 in/in/°F at room temperature to 8.9 × 10^-6 in/in/°F at 1000°F (538°C). This property helps minimize thermal stresses and maintains the integrity of structures and systems during thermal cycling.

The thermal conductivity of Inconel 625 seamless tubing is moderate, typically around 6.7 BTU/hr-ft-°F at room temperature, increasing slightly with temperature. This characteristic allows for controlled heat transfer, which can be advantageous in certain high-temperature applications where heat management is critical.

Temperature Resistance Mechanisms of Inconel 625

Formation of Protective Oxide Layers

One of the key mechanisms behind the exceptional temperature resistance of Inconel 625 tube is the formation of protective oxide layers on its surface when exposed to high temperatures. The chromium in the alloy reacts with oxygen to form a thin, adherent chromium oxide (Cr2O3) layer. This layer acts as a barrier, significantly slowing down further oxidation of the underlying metal.

The oxide layer formed on Inconel 625 is not only stable at high temperatures but also self-healing. If the layer is damaged or breached, chromium from the alloy quickly reacts with oxygen to repair the protective barrier. This continuous process ensures long-term protection against oxidation, even in severely corrosive environments at elevated temperatures.

Solid Solution Strengthening

Inconel 625 pipe derives much of its strength and temperature resistance from a mechanism known as solid solution strengthening. In this process, elements like molybdenum and niobium dissolve into the nickel-chromium matrix, creating a homogeneous solid solution. These solute atoms cause lattice distortions in the crystal structure of the alloy, impeding the movement of dislocations.

This strengthening mechanism is particularly effective at high temperatures. While many alloys lose strength as temperature increases due to increased atomic mobility, the solid solution strengthening in Inconel 625 remains effective, maintaining the alloy's strength and creep resistance at elevated temperatures. This is why Inconel 625 seamless pipe can maintain its structural integrity in applications where other materials would fail.

Precipitation Hardening Effects

Although Inconel 625 is primarily strengthened through solid solution mechanisms, it can also undergo a degree of precipitation hardening, particularly during long-term exposure to high temperatures. This process involves the formation of fine, dispersed particles within the alloy matrix, further enhancing its strength and temperature resistance.

The primary precipitates in Inconel 625 seamless tubing are gamma double prime (Ni3Nb) and various carbides. These precipitates form slowly over time at elevated temperatures, contributing to the alloy's excellent long-term stability and creep resistance. However, it's important to note that excessive precipitation can lead to embrittlement, which is why the heat treatment and service conditions of Inconel 625 must be carefully controlled to optimize its properties.

Applications Leveraging Inconel 625's Temperature Resistance

Aerospace and Gas Turbine Components

The aerospace industry extensively utilizes Inconel 625 tube for its exceptional temperature resistance and strength. In aircraft and rocket engines, where components are subjected to extreme temperatures and stresses, Inconel 625 proves invaluable. It's commonly used in exhaust systems, thrust reversers, and various engine components that must withstand high temperatures while maintaining structural integrity.

In gas turbines, both for aviation and power generation, Inconel 625 seamless pipe finds applications in combustion chambers, turbine shroud rings, and transition ducts. Its ability to resist oxidation and maintain strength at high temperatures ensures reliable performance and extended service life of these critical components, contributing to the overall efficiency and safety of turbine systems.

Chemical Processing Equipment

The chemical processing industry relies heavily on Inconel 625 pipe for equipment that must operate in corrosive environments at elevated temperatures. Heat exchangers, reaction vessels, and distillation columns often incorporate Inconel 625 components, especially in processes involving aggressive chemicals or high-temperature reactions.

In particular, Inconel 625 seamless tubing is prized for its resistance to stress corrosion cracking and pitting in chloride-rich environments at high temperatures. This makes it an ideal material for processing equipment in industries such as petrochemical refining, where materials are exposed to a combination of corrosive substances and high temperatures.

Marine and Offshore Applications

The marine and offshore industries leverage the temperature resistance and corrosion resistance of Inconel 625 in various applications. Subsea equipment, including risers, flowlines, and umbilicals, often incorporates Inconel 625 components to withstand the harsh conditions of deep-sea environments, which can include high pressures, corrosive seawater, and elevated temperatures from geothermal activity or hot oil flows.

In offshore oil and gas platforms, Inconel 625 tube is used in exhaust systems, flare stacks, and process piping where resistance to both high temperatures and marine corrosion is crucial. The alloy's ability to maintain its properties in these demanding conditions ensures the longevity and reliability of critical offshore infrastructure.

Conclusion

Understanding the temperature resistance of Inconel 625 tube reveals its crucial role in advancing technological capabilities across various industries. Its exceptional ability to maintain strength and resist corrosion at extreme temperatures stems from a carefully engineered composition and unique microstructure. From forming protective oxide layers to leveraging solid solution strengthening, Inconel 625 demonstrates remarkable resilience in the most demanding environments. As industries continue to push the boundaries of what's possible in high-temperature applications, Inconel 625 seamless pipe and tubing remain at the forefront, enabling innovations in aerospace, chemical processing, and marine engineering. The enduring performance of this superior alloy underscores its importance in creating safer, more efficient, and more durable systems in our modern industrial landscape.

Contact Us

For more information about our high-quality Inconel 625 tubes and how they can benefit your specific application, please don't hesitate to reach out. Contact our team of experts at info@tsm-technology.com to discuss your needs and discover the perfect solution for your high-temperature challenges.