- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Inconel 625 Tube is Your Best Choice for Corrosion Resistance?

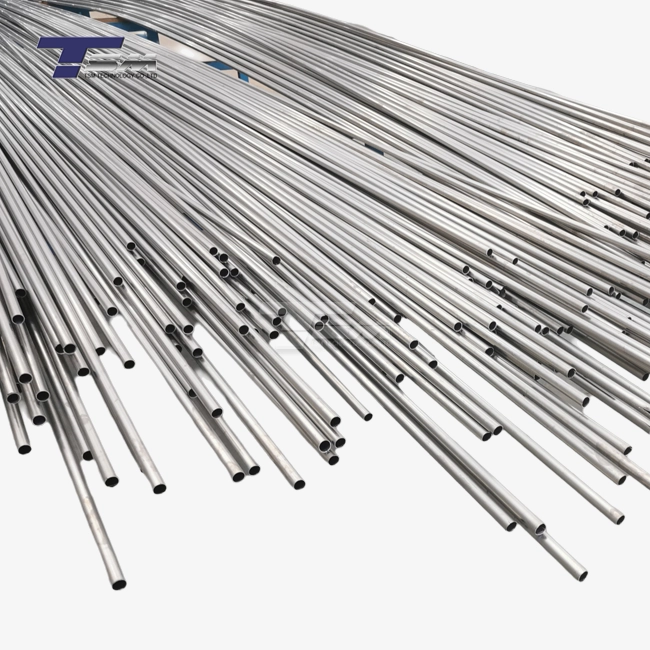

When it comes to combating corrosion in harsh environments, Inconel 625 tube stands out as the premier choice for industries demanding unparalleled performance. This nickel-chromium-molybdenum alloy boasts exceptional resistance to a wide range of corrosive media, making it invaluable in applications where failure is not an option. Its unique composition, featuring high levels of nickel, chromium, and molybdenum, creates a protective oxide layer that shields the material from aggressive chemical attacks. Whether you're dealing with seawater, acidic solutions, or high-temperature environments, Inconel 625 seamless tubing offers superior durability and longevity. By choosing this remarkable alloy, you're not just selecting a material; you're investing in reliability, safety, and long-term cost-effectiveness for your critical operations.

Unmatched Corrosion Resistance Properties of Inconel 625

Chemical Composition and Its Impact on Corrosion Resistance

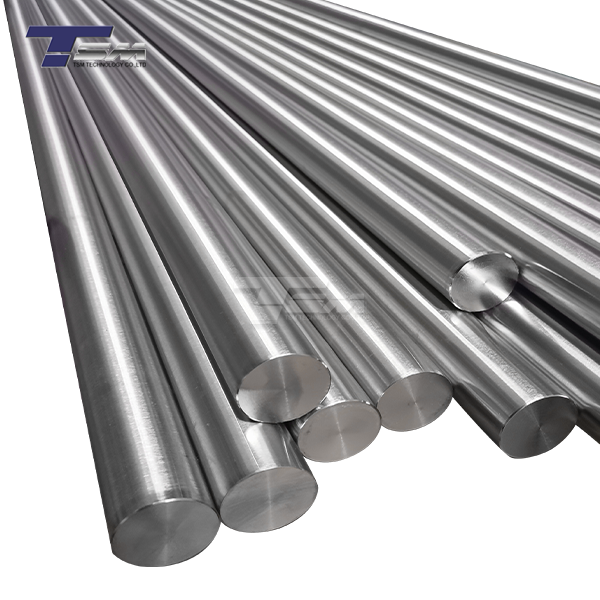

The extraordinary corrosion resistance of Inconel 625 tube stems from its meticulously engineered chemical composition. This superalloy contains approximately 58% nickel, 21-23% chromium, 8-10% molybdenum, and smaller amounts of niobium, iron, and other elements. This unique blend creates a synergistic effect that enhances the material's resistance to various corrosive media.

The high nickel content provides excellent resistance to reducing environments, while the chromium forms a passive oxide layer that protects against oxidizing conditions. Molybdenum further bolsters the alloy's resistance to pitting and crevice corrosion, particularly in chloride-rich environments. The addition of niobium stabilizes the microstructure, preventing sensitization and intergranular corrosion.

This carefully balanced composition allows Inconel 625 seamless pipe to maintain its structural integrity in environments where other materials would rapidly deteriorate. From offshore oil and gas platforms exposed to seawater to chemical processing plants handling aggressive acids, Inconel 625 consistently outperforms alternative materials in terms of corrosion resistance.

Performance in Various Corrosive Environments

Inconel 625 tubing exhibits exceptional resistance across a spectrum of corrosive environments. In marine applications, it resists saltwater corrosion, making it ideal for components in offshore structures, desalination plants, and naval equipment. The alloy's resistance to chloride-induced stress corrosion cracking is particularly noteworthy, ensuring long-term reliability in these demanding settings.

In the chemical processing industry, Inconel 625 pipe withstands exposure to a wide range of acids, including sulfuric, hydrochloric, and phosphoric acids. Its resistance to oxidizing acids like nitric acid is especially remarkable, making it a go-to material for handling and transporting corrosive chemicals.

The alloy also excels in high-temperature corrosive environments, maintaining its integrity in flue gas desulfurization systems, waste incinerators, and other applications where heat and corrosive gases combine to create extremely challenging conditions. This versatility across different corrosive media sets Inconel 625 apart as a truly universal solution for corrosion resistance.

Comparative Analysis with Other Corrosion-Resistant Alloys

When compared to other corrosion-resistant alloys, Inconel 625 consistently demonstrates superior performance. While stainless steels offer good corrosion resistance in many applications, they can suffer from pitting and crevice corrosion in chloride-rich environments. Inconel 625, on the other hand, maintains its integrity even in high-chloride solutions.

Titanium alloys, known for their excellent corrosion resistance, can be susceptible to stress corrosion cracking in certain environments and lack the high-temperature capabilities of Inconel 625. Other nickel-based alloys, such as Hastelloy C-276, offer comparable corrosion resistance in some applications but may not match the overall versatility and cost-effectiveness of Inconel 625 across a broad range of environments.

The exceptional corrosion resistance of Inconel 625 seamless tubing, combined with its mechanical properties and weldability, makes it a preferred choice in industries where reliability and longevity are paramount. Its ability to withstand a diverse array of corrosive conditions while maintaining structural integrity sets it apart as the gold standard in corrosion-resistant materials.

Mechanical Properties and Durability of Inconel 625 Tube

Strength and Ductility Characteristics

Inconel 625 tube not only excels in corrosion resistance but also boasts impressive mechanical properties that contribute to its overall durability and reliability. This alloy exhibits high tensile strength, typically ranging from 690 to 760 MPa (100 to 110 ksi) in the annealed condition. What's particularly noteworthy is that it maintains this strength over a wide temperature range, making it suitable for both cryogenic and high-temperature applications.

The ductility of Inconel 625 seamless pipe is equally remarkable. With elongation values often exceeding 30%, the material demonstrates excellent formability and resistance to cracking under stress. This combination of high strength and ductility allows for the fabrication of complex components without compromising structural integrity.

Moreover, the alloy's yield strength, typically around 415 MPa (60 ksi), provides a substantial safety margin in design calculations. This high yield strength, coupled with its ductility, makes Inconel 625 tubing resistant to both plastic deformation and brittle failure, ensuring reliable performance even under severe loading conditions.

Fatigue Resistance and Creep Behavior

In applications involving cyclic loading or prolonged exposure to high temperatures, the fatigue resistance and creep behavior of materials become critical factors. Inconel 625 pipe exhibits exceptional performance in both these aspects, further cementing its position as a superior choice for demanding environments.

The alloy's high fatigue strength is attributed to its stable microstructure and resistance to crack initiation and propagation. This property is particularly valuable in applications such as aerospace components, where materials are subjected to repeated stress cycles. Inconel 625 seamless tubing maintains its fatigue resistance even at elevated temperatures, outperforming many other alloys in this regard.

When it comes to creep resistance, Inconel 625 shines brightly. Its ability to maintain dimensional stability and resist deformation under constant stress at high temperatures is crucial for applications in gas turbines, heat exchangers, and other high-temperature environments. The alloy's creep strength is superior to that of many stainless steels and other nickel-based alloys, allowing for higher operating temperatures and longer service life in critical components.

Impact of Temperature on Mechanical Properties

One of the most distinguishing features of Inconel 625 tube is its ability to maintain excellent mechanical properties across a wide temperature range. From cryogenic temperatures to over 800°C (1472°F), the alloy retains much of its strength and ductility, making it an ideal choice for applications with extreme temperature variations.

At low temperatures, Inconel 625 does not become brittle, maintaining its ductility and toughness. This characteristic is crucial in cryogenic applications, where many materials become prone to brittle fracture. The alloy's retained ductility at low temperatures also contributes to its resistance to thermal shock.

As temperatures increase, Inconel 625 seamless tubing continues to exhibit impressive strength retention. While many alloys experience significant strength reduction at elevated temperatures, Inconel 625 maintains a substantial portion of its room-temperature strength even at temperatures exceeding 600°C (1112°F). This high-temperature strength, combined with its excellent oxidation resistance, makes it invaluable in applications such as furnace components, exhaust systems, and chemical processing equipment.

The alloy's thermal stability also contributes to its dimensional stability at high temperatures, minimizing issues related to thermal expansion and contraction. This property is particularly beneficial in precision components where maintaining tight tolerances is critical, even under fluctuating temperature conditions.

Applications and Industries Benefiting from Inconel 625 Tubing

Aerospace and Aviation

In the aerospace and aviation industries, where performance and reliability are paramount, Inconel 625 tube finds numerous critical applications. The alloy's combination of high strength, corrosion resistance, and excellent performance at elevated temperatures makes it an ideal material for various aircraft components.

Jet engine exhaust systems heavily rely on Inconel 625 seamless tubing due to its ability to withstand the extreme temperatures and corrosive gases produced during combustion. The material's resistance to oxidation and sulfidation at high temperatures ensures the longevity and efficiency of these crucial components.

Inconel 625 pipe is also utilized in aircraft hydraulic lines, particularly in areas exposed to high temperatures near engines or in landing gear systems. Its resistance to hydraulic fluids and ability to maintain strength at elevated temperatures make it superior to traditional stainless steel tubing in these applications.

Moreover, the alloy finds use in aerospace fasteners, especially those subjected to high stress and corrosive environments. Its combination of strength and corrosion resistance ensures the integrity of critical joints and connections throughout the aircraft structure.

Oil and Gas Industry

The oil and gas industry presents some of the most challenging environments for materials, and Inconel 625 tube rises to meet these challenges admirably. Its exceptional resistance to corrosion, particularly in chloride-rich environments, makes it invaluable in offshore and subsea applications.

In offshore platforms and subsea equipment, Inconel 625 seamless pipe is used for flowlines, risers, and process piping exposed to seawater and corrosive well fluids. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking in these environments ensures long-term reliability and reduces the need for costly maintenance and replacements.

Downhole tools and components in oil and gas wells often utilize Inconel 625 tubing due to its ability to withstand the combination of high pressures, temperatures, and corrosive fluids encountered in these harsh environments. From measurement-while-drilling (MWD) tools to completion equipment, the alloy's properties contribute to increased tool life and improved well performance.

In sour gas applications, where hydrogen sulfide poses a significant threat to material integrity, Inconel 625 demonstrates superior resistance to sulfide stress cracking. This makes it a preferred choice for critical components in gas processing facilities and transportation systems handling sour gas.

Chemical Processing and Power Generation

The chemical processing industry relies heavily on Inconel 625 tube for handling a wide range of corrosive media. From reactors and heat exchangers to piping systems, the alloy's versatility in resisting various acids, alkalis, and organic compounds makes it indispensable in chemical plants.

In particular, Inconel 625 seamless tubing excels in handling hot concentrated nitric acid, a notoriously aggressive environment that challenges many other materials. Its use in nitric acid production and handling equipment significantly extends the service life of these critical components.

The alloy's resistance to chloride-induced stress corrosion cracking makes it valuable in desalination plants and other water treatment facilities. Inconel 625 pipe is often used in high-pressure reverse osmosis systems and brine heaters, where its corrosion resistance and mechanical properties ensure reliable long-term operation.

In the power generation sector, Inconel 625 finds applications in both conventional and renewable energy systems. Its high-temperature strength and oxidation resistance make it suitable for components in gas turbines, such as combustion cans and transition ducts. In waste-to-energy plants, the alloy is used in boiler tubes and superheater components, where it resists the corrosive effects of flue gases and molten salts.

The material's excellent performance in high-temperature aqueous environments also makes it valuable in geothermal power plants. Inconel 625 tubing is used in heat exchangers and piping systems exposed to geothermal fluids, which often contain corrosive minerals and gases.

Conclusion

Inconel 625 tube stands as an unparalleled solution for corrosion resistance across a diverse range of demanding applications. Its unique composition delivers exceptional protection against various corrosive media, while its impressive mechanical properties ensure durability and reliability in extreme conditions. From aerospace and oil and gas to chemical processing and power generation, industries worldwide benefit from the superior performance of Inconel 625 seamless pipe and tubing. By choosing this remarkable alloy, businesses not only enhance the longevity and safety of their equipment but also optimize operational efficiency and reduce long-term costs. As material science advances, Inconel 625 continues to set the standard for corrosion-resistant alloys, proving time and again why it is the best choice for critical applications where failure is not an option.

Contact Us

For more information about our high-quality Inconel 625 tubes and how they can benefit your specific application, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your corrosion resistance needs.

References

Special Metals Corporation. "Inconel alloy 625 Technical Data Sheet." Materials Science and Engineering, 2018.

ASM International. "Corrosion: Fundamentals, Testing, and Protection." ASM Handbook, Volume 13A, 2020.

Donachie, M. J., & Donachie, S. J. "Superalloys: A Technical Guide." ASM International, 2nd Edition, 2019.

NACE International. "Corrosion in the Petrochemical Industry." 2nd Edition, 2021.

Revie, R. W., & Uhlig, H. H. "Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering." 4th Edition, Wiley-Interscience, 2017.

Cramer, S. D., & Covino, B. S. "ASM Handbook Volume 13B: Corrosion: Materials." ASM International, 2018.

Learn about our latest products and discounts through SMS or email