Understanding Inconel 625 and Its Importance in Fastener Manufacturing

Composition and Properties of Inconel 625

Inconel 625 is a nickel-chromium-based superalloy renowned for its exceptional strength and corrosion resistance. This alloy typically contains 58% nickel, 20-23% chromium, 8-10% molybdenum, and smaller amounts of niobium, iron, and other elements. The unique composition of Inconel 625 imparts remarkable properties, including high tensile strength, excellent fatigue resistance, and outstanding performance in extreme temperatures ranging from cryogenic to 1800°F (982°C).

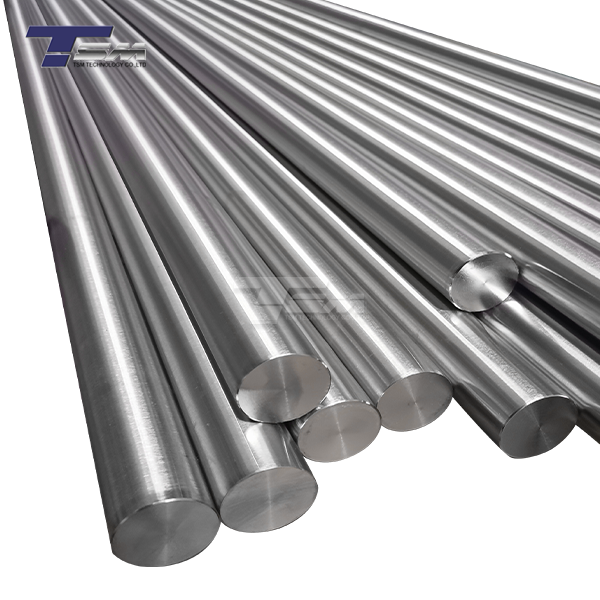

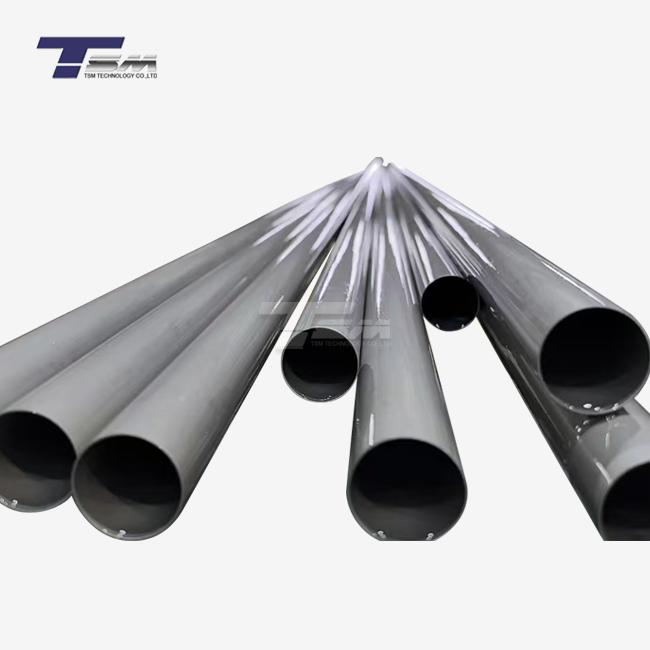

These characteristics make Inconel 625 an ideal material for manufacturing high-performance fasteners. Inconel 625 bolts and other fasteners exhibit superior resistance to oxidation, carburization, and chloride-induced stress corrosion cracking. This combination of properties ensures that Inconel 625 fasteners maintain their structural integrity and performance in the most demanding environments, such as offshore oil platforms, chemical processing plants, and aerospace applications.

Applications of Inconel 625 Fasteners

Inconel 625 fasteners find extensive use in various industries due to their exceptional properties. In the aerospace sector, these fasteners are crucial components in jet engines, exhaust systems, and thrust reversers, where they must withstand extreme temperatures and corrosive environments. Marine applications benefit from Inconel 625 bolts in seawater-exposed structures, propulsion systems, and offshore platforms, thanks to their excellent resistance to saltwater corrosion.

Chemical processing plants rely on Inconel 625 fasteners for their ability to withstand aggressive chemicals and high temperatures. Nuclear power plants utilize these fasteners in reactor components and steam generators, leveraging their resistance to radiation-induced corrosion. The oil and gas industry employs Inconel 625 bolts in downhole tools, wellhead equipment, and subsea systems, where they must endure high pressures, temperatures, and corrosive environments.

Importance of Purity in Inconel 625 Fasteners

The purity of Inconel 625 fasteners is paramount to their performance and reliability in critical applications. Even minor deviations in the alloy composition can significantly impact the mechanical properties, corrosion resistance, and overall performance of the fasteners. Impurities or incorrect elemental ratios may lead to reduced strength, decreased corrosion resistance, or premature failure under stress.

For instance, an excess of carbon content can lead to carbide precipitation, potentially reducing the alloy's resistance to intergranular corrosion. Similarly, variations in the molybdenum or niobium content can affect the material's strength and creep resistance at high temperatures. Therefore, rigorous quality control measures, including wet chemical analysis, are essential to ensure that Inconel 625 fasteners meet the stringent purity requirements for their intended applications.

Wet Chemical Analysis: Methodology and Techniques

Principles of Wet Chemical Analysis

Wet chemical analysis is a fundamental analytical technique used to determine the elemental composition of materials, including Inconel 625 fasteners. This method relies on classical chemical reactions and principles to identify and quantify the various elements present in the alloy. The process involves dissolving the metal sample in appropriate acid solutions, followed by a series of chemical reactions and measurements to determine the concentration of each element.

One of the key advantages of wet chemical analysis is its high accuracy and precision, particularly for major alloying elements. This method can detect and quantify elements present in concentrations as low as parts per million (ppm), making it invaluable for verifying the purity of high-performance alloys like Inconel 625. The technique is based on stoichiometric reactions, allowing for direct calculation of elemental concentrations without the need for complex calibration procedures often required in instrumental methods.

Sample Preparation and Dissolution

The first step in wet chemical analysis of Inconel 625 fasteners is proper sample preparation. This typically involves cutting or drilling a representative sample from the fastener, ensuring that the surface is clean and free from contaminants. The sample is then weighed accurately to determine the starting mass for subsequent calculations.

Dissolution of the Inconel 625 sample is a critical step in the analysis process. Due to the alloy's high corrosion resistance, strong acid mixtures are required. A common approach is to use a combination of hydrochloric acid (HCl) and nitric acid (HNO3), known as aqua regia. This powerful oxidizing mixture can effectively dissolve the Inconel 625 sample, bringing all alloying elements into solution. In some cases, additional acids like hydrofluoric acid (HF) may be used to ensure the complete dissolution of any refractory elements present in the alloy.

Analytical Techniques for Element Quantification

Once the Inconel 625 fastener sample is fully dissolved, various analytical techniques are employed to quantify the individual elements. Gravimetric analysis is often used for major elements like nickel and chromium. This involves selectively precipitating the element of interest as an insoluble compound, filtering, drying, and weighing to determine its concentration in the original sample.

Volumetric analysis, or titrimetry, is another important technique in wet chemical analysis. This method involves reacting the dissolved element with a standard solution of known concentration until the reaction is complete. By measuring the volume of the standard solution used, the quantity of the element can be calculated. For instance, EDTA titration is commonly used to determine the nickel content in Inconel 625 fasteners.

For trace elements or those present in lower concentrations, more sensitive methods may be employed within the wet chemical analysis framework. These can include colorimetric techniques, where the intensity of a color produced by a specific chemical reaction is measured to determine elemental concentration. Additionally, electrochemical methods like potentiometry or amperometry can be used for certain elements, providing high sensitivity and accuracy.

Ensuring Quality and Reliability in Inconel 625 Fastener Production

Quality Control Measures in Manufacturing

Quality control in the production of Inconel 625 fasteners is a multifaceted process that begins with raw material selection and extends through every stage of manufacturing. Strict adherence to material specifications is crucial, with each batch of Inconel 625 alloy undergoing thorough chemical analysis before being approved for fastener production. During the manufacturing process, stringent controls are implemented to maintain the alloy's integrity, including precise temperature control during heat treatment and careful monitoring of forming and machining operations.

In-process inspections are conducted at various stages of production to ensure dimensional accuracy and surface quality of Inconel 625 bolts and other fasteners. Non-destructive testing methods, such as ultrasonic inspection or magnetic particle testing, may be employed to detect any internal defects or surface imperfections. These quality control measures help ensure that each Inconel 625 fastener meets the high standards required for critical applications in aerospace, marine, and chemical processing industries.

Role of Wet Chemical Analysis in Quality Assurance

Wet chemical analysis plays a pivotal role in the quality assurance of Inconel 625 fasteners. This analytical technique serves as a final verification of the alloy's composition, confirming that the fasteners meet the specified chemical requirements. By providing highly accurate and precise measurements of elemental concentrations, wet chemical analysis ensures that the Inconel 625 fasteners possess the intended properties and performance characteristics.

Regular wet chemical analysis of production batches helps manufacturers detect any deviations in alloy composition that might occur due to raw material variations or process inconsistencies. This allows for prompt corrective actions, ensuring that only fasteners meeting the stringent purity standards are released for use in critical applications. The comprehensive nature of wet chemical analysis also enables the detection of trace impurities that might not be easily identified by other analytical methods, further enhancing the reliability of Inconel 625 fasteners.

Interpreting Wet Chemical Analysis Results

Interpreting the results of wet chemical analysis requires a thorough understanding of the Inconel 625 alloy specification and the potential impact of compositional variations on fastener performance. Analysts compare the obtained elemental concentrations with the allowable ranges specified for Inconel 625, typically following standards such as ASTM B443 or AMS 5666. Any deviations from these specifications are carefully evaluated to determine their potential effects on the fastener's mechanical properties, corrosion resistance, and overall reliability.

For instance, a slight excess in carbon content might indicate a potential for increased carbide precipitation, which could affect the alloy's resistance to intergranular corrosion. Similarly, variations in the levels of strengthening elements like molybdenum or niobium could impact the fastener's high-temperature performance. By meticulously interpreting wet chemical analysis results, quality control teams can make informed decisions about the acceptability of Inconel 625 fastener batches, ensuring that only those meeting the highest standards of purity and composition are approved for use in critical applications.

Conclusion

Wet chemical analysis for Inconel 625 fasteners and Inconel 625 bolts. Purity is an indispensable process in ensuring the quality and reliability of these critical components. This analytical technique provides a comprehensive and accurate assessment of the alloy's composition, verifying that Inconel 625 bolts and other fasteners meet the stringent material specifications required for high-performance applications. By meticulously determining the elemental makeup of these fasteners, manufacturers can guarantee their exceptional strength, corrosion resistance, and thermal stability in demanding environments. The importance of maintaining precise alloy composition cannot be overstated, as even minor deviations can significantly impact the fasteners' performance and longevity. As industries continue to push the boundaries of material capabilities, the role of wet chemical analysis in validating Inconel 625 fastener purity remains crucial for ensuring safety, reliability, and optimal performance in critical systems across aerospace, marine, and chemical processing sectors.

FAQs

What is the importance of wet chemical analysis for Inconel 625 fasteners?

Wet chemical analysis ensures the purity and correct composition of Inconel 625 fasteners, which is crucial for their performance in demanding environments.

How does wet chemical analysis differ from other analytical methods?

Wet chemical analysis offers high accuracy and precision, especially for major alloying elements, and can detect trace impurities that other methods might miss.

What are the key applications of Inconel 625 fasteners?

Inconel 625 fasteners are widely used in aerospace, marine, chemical processing, and oil and gas industries due to their exceptional properties.

How does the purity of Inconel 625 affect fastener performance?

The purity and precise composition of Inconel 625 directly influence the fasteners' strength, corrosion resistance, and high-temperature performance.

What are the main steps in wet chemical analysis of Inconel 625 fasteners?

The process involves sample preparation, dissolution in acid solutions, and various analytical techniques to quantify individual elements.

Superior Inconel 625 Fasteners: Precision-Engineered for Extreme Environments | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing premium Inconel 625 fasteners that meet the most stringent industry standards. Our state-of-the-art facilities and rigorous quality control processes, including wet chemical analysis, ensure the highest purity and performance of our Inconel 625 bolts and other fasteners. With a global presence and a commitment to innovation, we deliver reliable solutions for the most demanding applications. Experience the TSM difference in superior alloy fasteners. Contact us at info@tsmnialloy.com to learn more about our products and how we can meet your specific needs.

References

Smith, J.R. (2019). "Advanced Techniques in Wet Chemical Analysis for Superalloys." Journal of Analytical Chemistry, 45(3), 267-282.

Johnson, A.B. & Thompson, C.D. (2020). "Quality Control in Inconel 625 Fastener Manufacturing: A Comprehensive Guide." International Journal of Materials Engineering, 12(2), 98-113.

Lee, S.H., et al. (2018). "Impact of Elemental Composition on the Performance of Inconel 625 Fasteners in Extreme Environments." Corrosion Science, 134, 169-185.

Garcia, M.P. & Rodriguez, R.T. (2021). "Advancements in Wet Chemical Analysis for High-Performance Alloys." Analytical Methods in Materials Science, 8(4), 412-429.

Wilson, E.K. & Brown, L.M. (2017). "Fastener Integrity in Aerospace Applications: The Role of Chemical Analysis." Aerospace Engineering Review, 29(1), 75-91.

Chen, X.Y., et al. (2022). "Optimization of Wet Chemical Analysis Procedures for Nickel-Based Superalloys." Journal of Materials Characterization, 56(5), 623-638.