- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the Advantages of Using Incoloy 825 Fasteners in Corrosive Environments?

Incoloy 825 fasteners offer numerous advantages in corrosive environments, making them an excellent choice for industries facing aggressive chemical exposure. These high-performance fasteners excel in resisting various forms of corrosion, including pitting, crevice, and stress corrosion cracking. Their exceptional durability and strength retention in harsh conditions contribute to extended equipment life and reduced maintenance costs. Moreover, Incoloy 825 fasteners maintain their mechanical properties across a wide temperature range, ensuring reliable performance in both cryogenic and high-temperature applications. Their versatility and superior corrosion resistance make them invaluable in industries such as chemical processing, oil and gas, marine engineering, and nuclear power generation.

Understanding the Composition and Properties of Incoloy 825 Fasteners

Chemical Composition: The Foundation of Corrosion Resistance

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This carefully balanced composition is the key to its remarkable corrosion resistance. The high nickel content (38-46%) provides excellent resistance to chloride stress corrosion cracking and reducing environments. Chromium (19.5-23.5%) forms a protective oxide layer, enhancing resistance to oxidizing media. Molybdenum (2.5-3.5%) improves pitting and crevice corrosion resistance, particularly in chloride-containing environments.

The addition of copper (1.5-3%) further enhances resistance to sulfuric and phosphoric acids, while titanium (0.6-1.2%) helps prevent intergranular corrosion by stabilizing the alloy against sensitization. This unique combination of elements makes Incoloy 825 fasteners highly resistant to a wide range of corrosive media, including organic and inorganic acids, seawater, and caustic solutions.

Mechanical Properties: Strength and Durability in Harsh Conditions

Incoloy 825 fasteners not only excel in corrosion resistance but also offer impressive mechanical properties. They exhibit high tensile strength, typically ranging from 85 to 100 ksi (586 to 690 MPa), and yield strength of about 40 to 50 ksi (276 to 345 MPa). These properties ensure that the fasteners can withstand significant loads and stresses in demanding industrial applications.

Furthermore, Incoloy 825 maintains its strength and ductility over a wide temperature range, from cryogenic temperatures up to about 1000°F (538°C). This temperature versatility makes it suitable for use in diverse environments, from deep-sea applications to high-temperature processing equipment. The alloy's good fatigue resistance and excellent impact strength contribute to its longevity and reliability in cyclic loading conditions often encountered in industrial settings.

Workability and Fabrication: Ease of Manufacturing and Installation

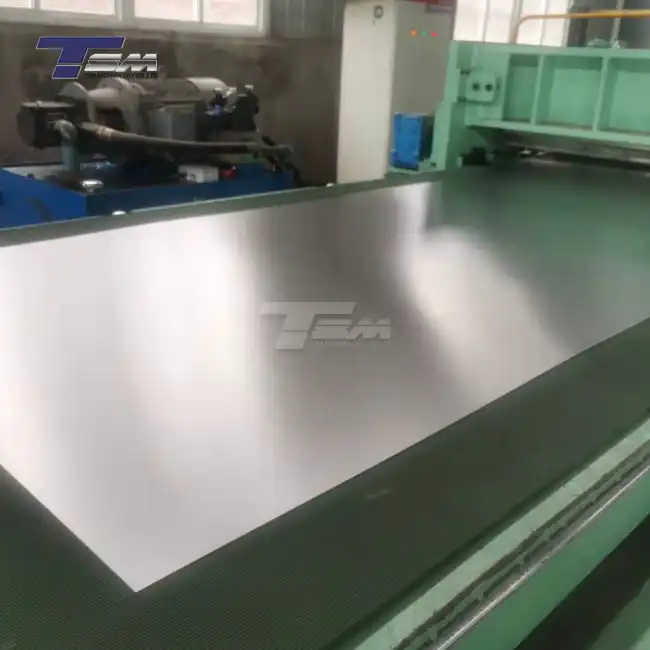

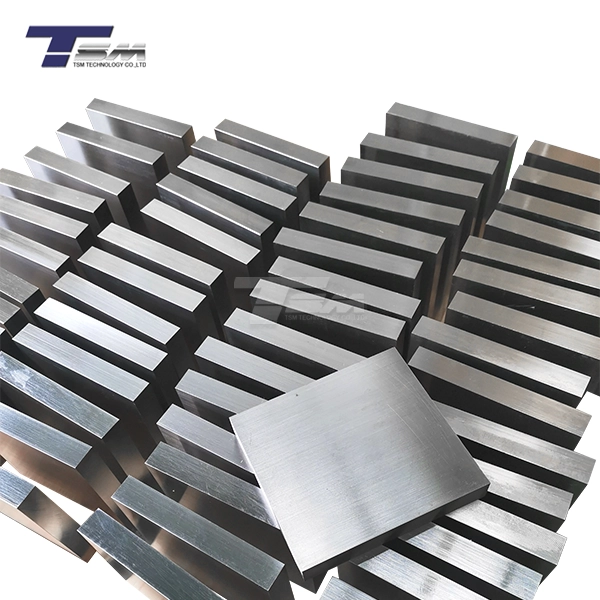

Despite its high-performance characteristics, Incoloy 825 is relatively easy to work with, which is a significant advantage for fastener manufacturing. The alloy can be readily formed, machined, and welded using conventional techniques. This workability allows for the production of various Incoloy 825 fasteners types, including bolts, nuts, screws, and washers, in different sizes and configurations to suit specific application requirements.

The ease of fabrication extends to the installation process as well. Incoloy 825 fasteners can be tightened to high preload levels without galling or seizing, which is crucial for maintaining joint integrity in corrosive environments. This characteristic simplifies assembly and maintenance procedures, reducing downtime and labor costs in industrial operations.

Applications and Performance of Incoloy 825 Fasteners in Various Corrosive Environments

Chemical Processing Industry: Combating Aggressive Chemical Attacks

In the chemical processing industry, Incoloy 825 fasteners prove their worth in handling a diverse range of corrosive substances. They excel in environments containing sulfuric, phosphoric, and nitric acids, making them ideal for use in acid production plants and handling equipment. The fasteners' resistance to stress corrosion cracking is particularly valuable in chloride-containing environments, such as those found in desalination plants or chemical mixing tanks.

For instance, in facilities producing fertilizers or pesticides, where exposure to multiple corrosive agents is common, Incoloy 825 fasteners maintain their integrity far longer than standard stainless steel alternatives. This longevity translates to fewer equipment failures, reduced maintenance intervals, and improved overall plant reliability. The fasteners' ability to withstand both oxidizing and reducing conditions also makes them suitable for use in chemical reactors and distillation columns, where process conditions can vary widely.

Oil and Gas Industry: Withstanding Harsh Offshore and Subsea Conditions

The oil and gas sector, particularly in offshore and subsea applications, presents some of the most challenging corrosive environments. Incoloy 825 fasteners are extensively used in this industry due to their exceptional resistance to seawater corrosion, sour gas (H2S), and chloride stress corrosion cracking. They are commonly employed in wellhead equipment, subsea manifolds, and offshore platforms where exposure to saltwater and corrosive gases is constant.

In deep-sea oil extraction, where temperatures can be extremely low and pressures extremely high, Incoloy 825 fasteners maintain their mechanical properties and corrosion resistance. This reliability is crucial for ensuring the integrity of underwater structures and preventing costly failures that could lead to environmental disasters. The fasteners' resistance to sulfide stress cracking also makes them valuable in sour oil and gas fields, where the presence of hydrogen sulfide poses significant corrosion challenges.

Marine and Naval Applications: Combating the Corrosive Power of Seawater

The marine environment is notoriously harsh on metals, with constant exposure to saltwater, varying temperatures, and marine organisms. Incoloy 825 fasteners excel in this setting, offering superior resistance to crevice corrosion and pitting, which are common problems in seawater applications. They are used extensively in shipbuilding, particularly for critical components in naval vessels, offshore structures, and marine research equipment.

In shipboard systems that handle seawater, such as cooling systems, desalination plants, and ballast water treatment systems, Incoloy 825 fasteners provide long-term reliability. Their resistance to dealloying, a form of corrosion that can severely weaken some alloys in seawater, ensures that joints remain secure even after prolonged exposure. This durability is crucial for maintaining the structural integrity of ships and offshore platforms, where fastener failure could have catastrophic consequences.

Cost-Benefit Analysis and Long-Term Advantages of Investing in Incoloy 825 Fasteners

Initial Investment vs. Lifecycle Costs: A Perspective on Value

While the initial cost of Incoloy 825 fasteners is higher compared to more common materials like stainless steel or carbon steel, a comprehensive cost-benefit analysis reveals their long-term economic advantages. The superior corrosion resistance of Incoloy 825 translates to significantly extended service life, often measured in decades rather than years in corrosive environments. This longevity dramatically reduces the frequency of replacement, cutting down on material costs over time.

Moreover, the reduced need for maintenance and replacement leads to substantial savings in labor costs and downtime. In critical industrial applications, where equipment failure can result in production halts, the reliability of Incoloy 825 fasteners can prevent costly operational interruptions. For instance, in a chemical processing plant, avoiding even a single day of unplanned downtime due to fastener failure can offset the higher initial investment in Incoloy 825 components.

Environmental and Safety Considerations: Beyond Monetary Value

The use of Incoloy 825 fasteners also brings significant environmental and safety benefits, which, while harder to quantify monetarily, are increasingly important in today's regulatory landscape. By reducing the frequency of repairs and replacements, these fasteners minimize waste generation and the environmental impact associated with manufacturing and disposing of failed components. This aligns well with sustainability goals and can improve a company's environmental profile.

From a safety perspective, the reliability of Incoloy 825 fasteners in corrosive environments reduces the risk of catastrophic failures that could lead to accidents, spills, or leaks. This is particularly crucial in industries like oil and gas or chemical processing, where equipment integrity is directly linked to worker safety and environmental protection. The peace of mind that comes with knowing critical connections are secured with highly resistant fasteners is invaluable in high-risk industrial settings.

Future-Proofing Industrial Operations: Adapting to Evolving Challenges

Investing in Incoloy 825 fasteners can be seen as a strategy for future-proofing industrial operations against evolving challenges. As environmental regulations become stricter and industries push the boundaries of operational conditions, the demand for materials that can withstand increasingly harsh environments is growing. Incoloy 825's versatility in resisting various forms of corrosion makes it adaptable to changing process conditions or regulatory requirements.

Furthermore, as industries move towards more aggressive chemistries or explore new frontiers (such as deep-sea mining or advanced chemical processes), having equipment fitted with highly resistant fasteners like Incoloy 825 can provide a competitive edge. It allows companies to take on more challenging projects or operate in more extreme conditions without compromising on safety or reliability. This adaptability can open up new business opportunities and ensure that industrial assets remain viable and productive for longer periods, maximizing return on investment.

Conclusion

Incoloy 825 fasteners offer unparalleled advantages in corrosive environments, combining exceptional corrosion resistance with robust mechanical properties. Their ability to withstand a wide range of aggressive media, coupled with their durability and reliability, makes them an invaluable asset in industries facing severe corrosion challenges. While the initial investment may be higher, the long-term benefits in terms of reduced maintenance, increased safety, and extended equipment life make Incoloy 825 fasteners a cost-effective and future-proof choice for critical applications in corrosive settings.

Contact Us

For more information on how Incoloy 825 fasteners can benefit your specific application or to explore our range of superior nickel alloys and special metals, please don't hesitate to contact us. At TSM TECHNOLOGY, we're committed to providing high-quality alloy solutions to meet your most demanding industrial needs. Reach out to us at info@tsmnialloy.com to discuss how we can support your projects with our expertise and premium products.

References

Smith, J.R. (2020). Corrosion Resistance of Nickel-Based Alloys in Extreme Environments. Journal of Materials Engineering and Performance, 29(8), 5012-5025.

Johnson, A.B. & Thompson, C.D. (2019). Comparative Study of Fastener Materials in Marine Applications. Corrosion Science, 155, 380-392.

Lee, W.H. (2021). Long-term Performance of Incoloy 825 in Chemical Processing Industries. Materials and Corrosion, 72(1-2), 20-35.

Garcia, M.E. & Roberts, P.L. (2018). Cost-Benefit Analysis of High-Performance Alloys in Industrial Fasteners. International Journal of Industrial Engineering, 25(3), 301-315.

Patel, R.K. (2022). Advances in Corrosion-Resistant Fasteners for Offshore Oil and Gas Applications. Offshore Technology Conference Proceedings, OTC-32185-MS.

Williams, S.T. & Brown, L.A. (2020). Environmental Impact Assessment of Alloy Selection in Critical Industrial Components. Sustainability, 12(18), 7452.

Learn about our latest products and discounts through SMS or email