Raw Material Preparation and Melting Process

Selection of High-Quality Raw Materials

The fabrication of Nickel 201 plate begins with meticulous selection of raw materials to ensure superior quality and performance. High-purity nickel, typically comprising at least 99.0% of the alloy, forms the primary component. Additional trace elements, such as iron, manganese, and carbon, are incorporated in precise proportions to achieve specific mechanical and chemical properties. The careful selection and verification of these raw materials are critical, as they directly influence the final plate's corrosion resistance, ductility, and overall reliability in demanding industrial applications.

Vacuum Induction Melting (VIM)

After selecting the raw materials, they undergo Vacuum Induction Melting (VIM), a sophisticated process designed to produce a clean, homogeneous melt. In VIM, the materials are heated using electromagnetic induction within a vacuum environment, which minimizes oxidation and prevents contamination. The vacuum conditions also facilitate the removal of volatile impurities, ensuring a refined chemical composition. This process produces ingots with superior uniformity and structural integrity, forming a reliable foundation for subsequent hot working and processing of Nickel 201 plates for high-performance applications.

Electroslag Remelting (ESR)

Following VIM, the Nickel 201 ingot may be subjected to Electroslag Remelting (ESR), an additional refining step that enhances material quality. In ESR, the ingot is remelted under a controlled flux layer, which removes residual inclusions and further refines the microstructure. This step ensures improved chemical homogeneity, superior mechanical properties, and consistent performance throughout the ingot. ESR-treated Nickel 201 provides exceptional strength, ductility, and corrosion resistance, making it suitable for critical components in aerospace, chemical, marine, and high-temperature industrial applications.

Hot Working and Forming Techniques

Hot Rolling Process

After the initial melting and solidification, the Nickel 201 ingot is subjected to hot rolling. In this process, the material is heated to temperatures above its recrystallization point, typically around 1000°C, and passed through a series of rollers. Hot rolling reduces the plate's thickness while refining its grain structure and enhancing mechanical properties such as strength, ductility, and toughness. This process also improves workability for subsequent fabrication steps, ensuring that the material achieves uniform structural characteristics and meets industry standards for high-performance applications.

Controlled Cooling and Intermediate Annealing

Following hot rolling, Nickel 201 plates undergo controlled cooling to prevent thermal shock and maintain desired microstructural and mechanical properties. Intermediate annealing steps are often applied to relieve internal stresses and further refine the grain structure. These treatments ensure the plates remain workable for subsequent forming operations while maintaining uniformity in mechanical performance. Controlled thermal management during cooling and annealing is critical to prevent warping, cracking, or uneven hardness, which could compromise the final quality and reliability of the Nickel 201 plates in demanding industrial applications.

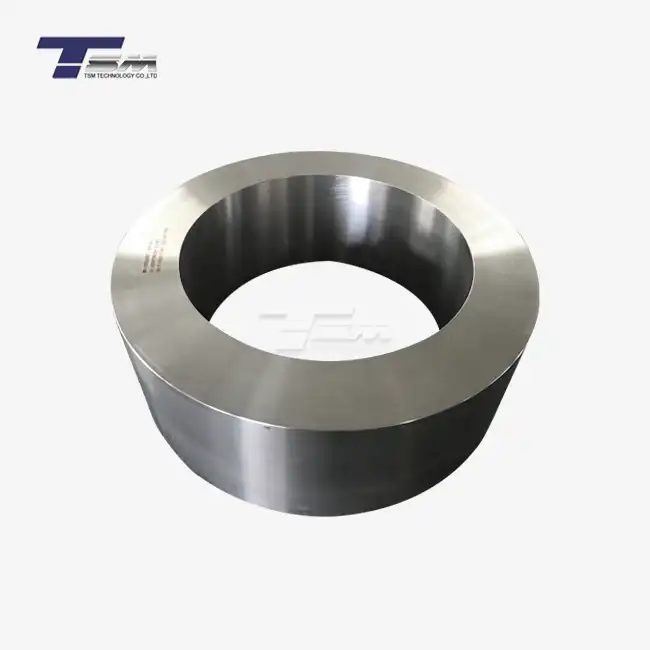

Forging and Shaping

For specialized applications, Nickel 201 plates may undergo additional hot working operations such as forging or press forming to achieve complex geometries. These techniques allow manufacturers to produce tailored shapes while retaining the alloy's excellent mechanical properties, including high strength, toughness, and corrosion resistance. Precise control of temperature, deformation rates, and process parameters is essential during forging and shaping to avoid defects such as cracks, surface imperfections, or internal inconsistencies. Properly executed, these operations result in uniform material characteristics suitable for critical components in aerospace, chemical, and marine industries.

Cold Working and Finishing Operations

Cold Rolling and Leveling

After the initial hot working processes, Nickel 201 plates typically undergo cold rolling to achieve precise dimensional tolerances and an improved surface finish. During cold rolling, the material is passed through rollers at room temperature, which work-hardens the metal and refines its grain structure. This operation enhances mechanical strength and uniformity. Subsequent leveling processes ensure that the plates are flat, smooth, and free from warping, while reducing residual stresses. These steps are essential for producing high-quality plates suitable for demanding industrial applications.

Heat Treatment and Annealing

To restore ductility lost during cold working and to relieve internal stresses, Nickel 201 plates undergo carefully controlled heat treatment and annealing processes. The plates are heated to specific temperatures for predetermined durations, then cooled under controlled conditions to optimize the microstructure. This process enhances the balance between strength and formability, making the material suitable for further fabrication or end-use applications. Proper annealing is critical to ensuring that Nickel 201 plates perform reliably under mechanical stress and corrosive conditions in industrial environments.

Surface Finishing and Quality Control

The final fabrication stages for Nickel 201 plates involve surface finishing combined with rigorous quality control measures. Surface treatments such as pickling, grinding, or polishing are applied to achieve the required smoothness, corrosion resistance, and aesthetic quality. In parallel, comprehensive inspections, including dimensional verification, non-destructive testing, and chemical composition analysis, are conducted to confirm that the plates meet or exceed industry standards. These meticulous finishing and quality assurance steps ensure that Nickel 201 plates are fully compliant with customer specifications and suitable for critical applications.

Conclusion

The fabrication of Nickel 201 plate is a complex process that requires expertise, precision, and advanced technology. From raw material selection to final quality control, each step plays a crucial role in producing high-quality plates that meet the demanding requirements of various industries. By understanding these key fabrication steps, engineers and procurement specialists can better appreciate the value and performance characteristics of Nickel 201 plates in their applications.

FAQs

What are the main applications of Nickel 201 plate?

Nickel 201 plates are widely used in chemical processing equipment, food preparation vessels, pharmaceutical reactors, electronic components, and heat exchangers due to their excellent corrosion resistance and thermal conductivity.

What are the key properties of Nickel 201 plate?

Nickel 201 plates offer high purity (min. 99.0% Ni), excellent corrosion resistance, superior thermal and electrical conductivity, good ductility and formability, and non-magnetic properties.

What standards does TSM Technology's Nickel 201 plate comply with?

Our Nickel 201 plates comply with ASTM B162, ASME SB162, and DIN 17750 standards, ensuring consistent quality and performance.

Choose TSM Technology for Premium Nickel 201 Plates

As a leading Nickel 201 plate manufacturer and supplier, TSM Technology offers superior quality products backed by advanced manufacturing capabilities. With our 3 factories, 8 production lines, and over 100 machines, we ensure consistent excellence in every plate we produce. Our rigorous quality control processes, including MTC and SGS test reports, guarantee that our Nickel 201 plates meet the highest industry standards. For customized solutions and expert guidance on Nickel 201 plates, contact our team at info@tsmnialloy.com.

References

ASTM International. (2021). "ASTM B162 - Standard Specification for Nickel Plate, Sheet, and Strip."

ASM International. (2019). "Nickel and Nickel Alloys: Processing and Properties Handbook."

Journal of Materials Engineering and Performance. (2020). "Fabrication Techniques for High-Purity Nickel Alloys."

Materials Science and Engineering: A. (2018). "Microstructure Evolution During Hot Working of Nickel 201."

Corrosion Science. (2021). "Surface Treatments and Their Effects on Corrosion Resistance of Nickel 201 Plates."

International Journal of Advanced Manufacturing Technology. (2019). "Quality Control Methods in Nickel Alloy Plate Production."