- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

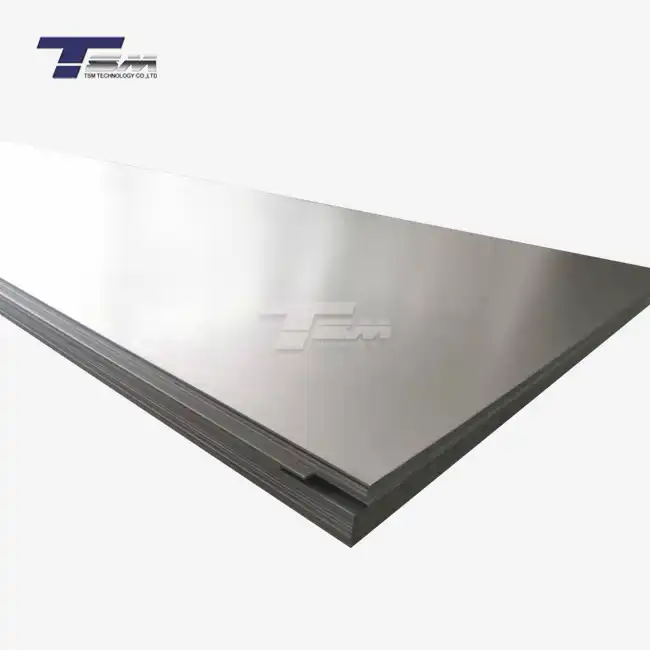

What Is Nickel 201 Plate and How Is It Made?

Nickel 201 plate is a high-purity nickel alloy material known for its excellent corrosion resistance and thermal properties. It contains a minimum of 99.0% nickel, making it ideal for applications requiring superior chemical and heat resistance. Nickel 201 plate is produced through a multi-step manufacturing process involving melting, casting, hot and cold rolling, heat treatment, and surface finishing. The result is a versatile material widely used in chemical processing, food preparation, pharmaceuticals, electronics, and heat exchange equipment.

Understanding Nickel 201 Plate Properties and Composition

Chemical Composition and Purity

Nickel 201 plate is composed of at least 99.0% pure nickel, with only trace amounts of other elements like carbon, manganese, iron, sulfur, and copper. This high purity gives Nickel 201 its exceptional corrosion resistance, particularly in caustic environments. The low carbon content (maximum 0.02%) also contributes to its excellent welding characteristics and resistance to intergranular corrosion.

Physical Properties

Nickel 201 plate exhibits several advantageous physical properties:

- Density: 8.89 g/cm³

- Melting Point: 1435°C

- Thermal Conductivity: 70 W/m·K

- Electrical Resistivity: 9.5 µΩ·cm

These properties make Nickel 201 ideal for applications that require high thermal and electrical conductivity, combined with corrosion resistance. Its relatively high melting point also allows it to maintain strength at elevated temperatures.

Mechanical Properties

Nickel 201 plate offers a good balance of strength and ductility:

- Tensile Strength: 380-550 MPa

- Yield Strength: 105-380 MPa

- Elongation: 30-50%

This combination of properties enables Nickel 201 to be easily formed and welded while still providing adequate strength for many industrial applications. Its ductility allows for complex forming operations without cracking or failure.

Manufacturing Process of Nickel 201 Plate

Melting and Casting

The manufacturing process of Nickel 201 plate starts with melting high-purity nickel in an electric arc or induction furnace under a controlled atmosphere. This ensures minimal contamination and consistent chemical composition. Once the molten metal reaches the desired temperature, it is cast into ingots or slabs using precise cooling methods. These cast forms serve as the foundation for later deformation processes that define the plate’s mechanical and physical characteristics.

Hot Rolling

During hot rolling, the cast slabs are reheated to approximately 1100°C–1250°C to enhance their plasticity. The material is then passed through multiple rolling stands to progressively reduce thickness while refining grain structure. This stage not only improves uniformity and strength but also eliminates internal defects formed during casting. The hot-rolled plate is cooled under controlled conditions to preserve structural integrity and ensure dimensional stability.

Cold Rolling and Annealing

After hot rolling, the Nickel 201 plate undergoes cold rolling to achieve precise thickness control and an improved surface finish. This mechanical deformation increases hardness and strength through work hardening. To restore ductility and relieve residual stresses, the plate is annealed at temperatures ranging from 750°C to 900°C. The annealing process produces a refined microstructure, resulting in a balance of strength, flexibility, and superior formability suitable for industrial applications.

Applications and Advantages of Nickel 201 Plate

Chemical Processing Equipment

Nickel 201 plate is a preferred material in the chemical processing industry because of its exceptional resistance to strong alkalis, acids, and other corrosive chemicals. It is widely used in the construction of evaporators, reaction vessels, heat exchangers, and caustic soda handling systems where durability and reliability are critical. Its excellent mechanical strength and oxidation resistance at elevated temperatures allow it to function efficiently in high-pressure, high-temperature environments, ensuring long service life and minimal maintenance downtime.

Food and Pharmaceutical Industries

In the food and pharmaceutical industries, Nickel 201 plate is prized for its purity, corrosion resistance, and ease of sterilization. The smooth, non-porous surface prevents microbial growth, ensuring hygienic conditions in the production of food additives, medical compounds, and sterile liquids. It is commonly used to manufacture sanitary piping, storage tanks, and processing vessels. Additionally, its non-magnetic nature eliminates any interference with precision instruments, maintaining product quality and compliance with strict regulatory standards.

Heat Exchangers and Thermal Management

Nickel 201 plate is extensively used in heat exchangers and advanced thermal management systems due to its high thermal conductivity and chemical stability. It is employed in the fabrication of tube sheets, baffles, and condensers that must perform reliably under corrosive and fluctuating temperature conditions. The material's ability to maintain mechanical strength during continuous heat transfer operations enhances system efficiency and operational safety. This combination of thermal performance and corrosion resistance significantly extends the equipment’s lifespan and reduces operational costs.

Conclusion

Nickel 201 plate is a versatile and high-performance material that serves a vital role across numerous industrial sectors. Its exceptional combination of corrosion resistance, thermal stability, mechanical strength, and formability makes it ideal for use in demanding environments such as chemical processing, food and pharmaceutical production, and heat transfer systems. The material's ability to maintain structural integrity under extreme temperatures and aggressive chemical exposure ensures reliable and long-lasting performance. As modern industries continue to evolve and face harsher operating conditions, Nickel 201 plate remains a preferred and trusted solution for engineers, designers, and manufacturers seeking both durability and efficiency.

FAQs

What are the key differences between Nickel 200 and Nickel 201?

Nickel 201 has a lower carbon content, offering better weldability and resistance to embrittlement at high temperatures.

Can Nickel 201 plate be welded?

Yes, Nickel 201 plate has excellent weldability due to its low carbon content.

What surface treatments are available for Nickel 201 plate?

Common surface treatments include sandblasting and anodizing, which can enhance corrosion resistance and appearance.

What standards govern Nickel 201 plate production?

Nickel 201 plate is typically produced to ASTM B162, ASME SB162, and DIN 17750 standards.

Is Nickel 201 plate magnetic?

No, Nickel 201 plate is non-magnetic, making it suitable for applications where magnetic properties could interfere.

Why Choose TSM Technology for Your Nickel 201 Plate Needs?

TSM Technology stands out as a leading Nickel 201 plate manufacturer and supplier, with 3 state-of-the-art factories, 8 production lines, and over 100 advanced machines. Our commitment to quality is evident in our strict adherence to ASTM B162, ASME SB162, and DIN 17750 standards. We offer customized sizes, thicknesses from 5-150 mm, and widths of 1000-2500 mm, along with various surface treatments. Our products are backed by MTC and SGS test reports, ensuring top-notch quality and reliability. For inquiries or to request a free sample, please contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "ASTM B162 - Standard Specification for Nickel Plate, Sheet, and Strip."

ASM International. (2019). "ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials."

Nickel Institute. (2020). "Nickel Plating Handbook."

Journal of Materials Engineering and Performance. (2018). "Corrosion Behavior of Nickel 201 in Various Industrial Environments."

Materials Science and Engineering: A. (2017). "Mechanical Properties and Microstructure Evolution of Nickel 201 under Different Processing Conditions."

Corrosion Science. (2019). "Long-term Corrosion Performance of Nickel Alloys in Aggressive Chemical Environments."

Learn about our latest products and discounts through SMS or email

_1739071581132.webp)