Key Certification Standards for Nickel Alloy Bars

ASTM Standards

ASTM International provides comprehensive standards for nickel alloy bars, covering various grades and specifications. Some of the most relevant ASTM standards include:

- ASTM B160: Standard Specification for Nickel Rod and Bar

- ASTM B164: Standard Specification for Nickel-Copper Alloy Rod, Bar, and Wire

- ASTM B166: Standard Specification for Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) Rod, Bar, and Wire

These standards define the chemical composition, mechanical properties, and dimensional requirements for different nickel alloy grades. They ensure consistency and reliability in the production and performance of nickel alloy bars across various industrial applications.

ASME Standards

The American Society of Mechanical Engineers (ASME) provides standards specific to pressure vessel and boiler applications. Key ASME standards for nickel alloy bars include:

- ASME SB160: Specification for Nickel Rod and Bar

- ASME SB164: Specification for Nickel-Copper Alloy Rod, Bar, and Wire

These standards are often referenced in conjunction with ASTM specifications and are crucial for applications in the power generation and petrochemical industries where high-temperature and high-pressure environments are common.

EN Standards

European Norm (EN) standards provide specifications for nickel alloy bars in the European market. Some relevant EN standards include:

- EN 10095: Heat Resistant Steels and Nickel Alloys

- EN 10204: Metallic Products - Types of Inspection Documents

These standards ensure compliance with European regulations and facilitate international trade by providing harmonized specifications for nickel alloy bars.

Industry-Specific Certification Standards

Aerospace Standards

The aerospace industry has stringent requirements for materials used in aircraft and spacecraft components. Key aerospace certification standards for nickel alloy bars include:

- AMS 5662: Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings

- AMS 5663: Nickel Alloy, Corrosion and Heat-Resistant, Bars, Wire, Forgings, and Rings

These standards ensure that nickel alloy bars meet the exacting requirements for strength, durability, and performance in aerospace applications. Compliance with these standards is often a prerequisite for suppliers in the aerospace supply chain.

Oil and Gas Industry Standards

The oil and gas industry relies on corrosion-resistant materials for various applications. Key standards in this sector include:

- NACE MR0175/ISO 15156: Materials for use in H2S-containing environments in oil and gas production

- API 6A: Specification for Wellhead and Christmas Tree Equipment

These standards ensure that nickel alloy bars used in oil and gas applications can withstand harsh, corrosive environments and maintain their integrity under extreme conditions.

Nuclear Industry Standards

The nuclear industry has unique requirements for materials used in reactor components. Relevant standards include:

- ASME BPVC Section III: Rules for Construction of Nuclear Facility Components

- RCC-M: Design and Construction Rules for Mechanical Components of PWR Nuclear Islands

These standards ensure that nickel alloy bars used in nuclear applications meet the stringent safety and performance requirements of the industry.

Quality Assurance and Traceability

Material Test Reports (MTR)

Material Test Reports (MTRs) are crucial documents that accompany nickel alloy bars and provide detailed information about the material's chemical composition, mechanical properties, and compliance with applicable standards. Key aspects of MTRs include:

- Chemical analysis results

- Mechanical test results (e.g., tensile strength, yield strength, elongation)

- Heat treatment details

- Certification of compliance with specified standards

MTRs ensure full traceability of the material from the manufacturer to the end-user, which is essential for quality control and regulatory compliance.

Non-Destructive Testing (NDT)

Non-destructive testing methods are often employed to verify the integrity of nickel alloy bars. Common NDT techniques include:

- Ultrasonic testing (UT)

- Magnetic particle inspection (MPI)

- Liquid penetrant testing (PT)

These tests help detect any internal or surface defects in the material, ensuring that only high-quality nickel alloy bars are used in critical applications.

Third-Party Certification

Many industries require third-party certification to validate compliance with specific standards. Notable certification bodies include:

- Lloyd's Register

- DNV GL

- TÜV

These organizations provide independent verification of a manufacturer's quality management system and product compliance, adding an extra layer of assurance for end-users.

Conclusion

Certification standards play a crucial role in ensuring the quality, reliability, and performance of nickel alloy bars across various industries. From general standards like ASTM and ASME to industry-specific certifications for aerospace, oil and gas, and nuclear applications, these specifications provide a framework for consistent material properties and performance. Manufacturers and end-users must stay informed about the relevant standards and ensure compliance to meet the demanding requirements of their respective applications. By adhering to these certification standards, the industry can maintain high levels of safety, efficiency, and reliability in critical operations involving nickel alloy bars.

FAQs

What are the most common certification standards for nickel alloy bars?

The most common standards are ASTM B160, ASME SB160, and EN 10095. These cover general specifications for nickel alloy bars across various industries.

How do aerospace standards differ from general industrial standards for nickel alloy bars?

Aerospace standards like AMS 5662 and AMS 5663 have more stringent requirements for mechanical properties, chemical composition, and quality control to ensure reliability in critical aerospace applications.

What information is typically included in a Material Test Report (MTR) for nickel alloy bars?

MTRs usually include chemical analysis results, mechanical test data, heat treatment details, and certification of compliance with specified standards.

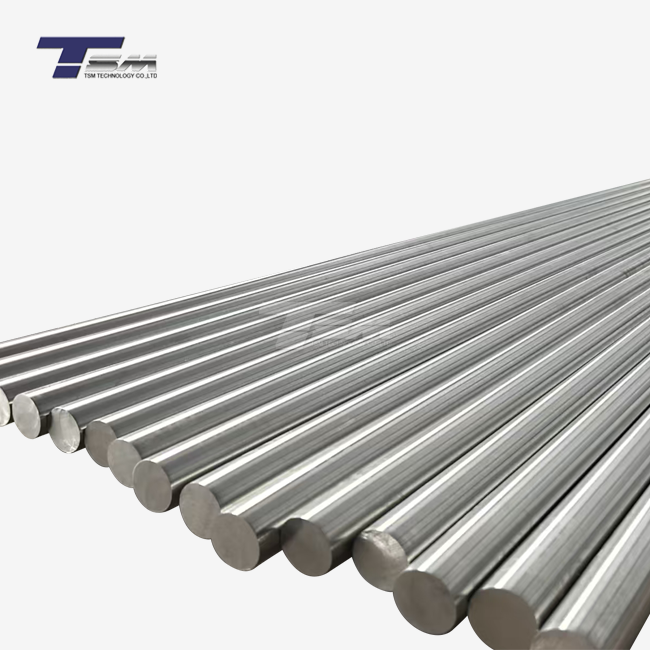

Experience the TSM Technology Advantage in Nickel Alloy Bars

At TSM Technology, we pride ourselves on delivering premium-quality nickel alloy bars that meet and exceed industry certification standards. With our state-of-the-art 50,000㎡ facility, we offer a wide range of nickel alloy grades, including Inconel, Hastelloy, and Monel, in various dimensions to suit your specific needs. Our AS9100D certification and rigorous quality control processes ensure that every bar we produce meets the most demanding aerospace, marine, and industrial standards. Experience unmatched reliability and precision with TSM Technology's nickel alloy bars. For more information or to discuss your requirements, please contact us at info@tsmnialloy.com.

References

ASTM International. (2021). "Standard Specification for Nickel Rod and Bar." ASTM B160-21.

American Society of Mechanical Engineers. (2019). "Specification for Nickel Rod and Bar." ASME SB160-2019.

European Committee for Standardization. (2018). "Heat Resistant Steels and Nickel Alloys." EN 10095:2018.

SAE International. (2020). "Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings." AMS 5662R.

NACE International. (2015). "Materials for use in H2S-containing environments in oil and gas production." NACE MR0175/ISO 15156.

American Petroleum Institute. (2018). "Specification for Wellhead and Christmas Tree Equipment." API Specification 6A, 21st Edition.