- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Size Options Exist for Nickel Alloy Bar in Oil & Gas Fabrication?

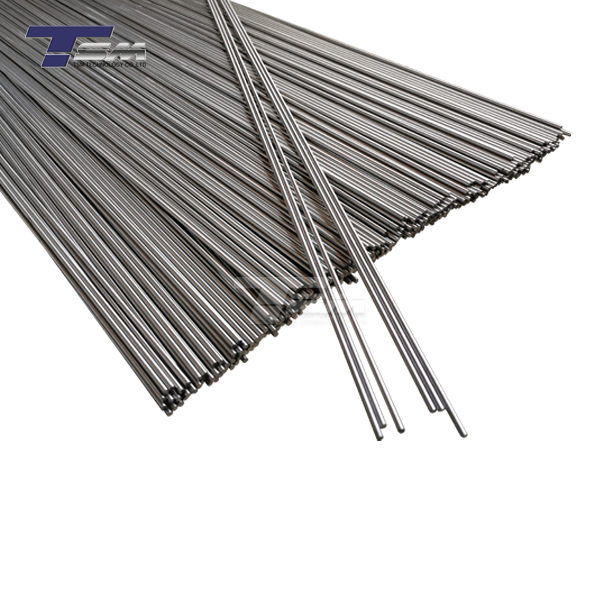

Nickel alloy bars play a crucial role in oil and gas fabrication, offering exceptional corrosion resistance and strength in harsh environments. For this industry, size options typically range from 5mm to 300mm in diameter, with lengths of 3000mm to 6000mm. These dimensions cater to various applications, from small precision components to large-scale structural elements. Common grades like Inconel 718, Hastelloy C276, and Monel 400 are available in round, square, and hexagonal shapes, allowing for versatility in design and fabrication processes. The specific size selection depends on factors such as pressure ratings, temperature requirements, and structural needs of the particular oil and gas equipment being manufactured.

Understanding Nickel Alloy Bar Specifications for Oil & Gas Applications

Standard Sizes and Customization Options

When it comes to nickel alloy bars in oil and gas fabrication, understanding the available size options is crucial for project success. Standard sizes typically range from 5mm to 300mm in diameter for round bars, with lengths spanning from 3000mm to 6000mm. However, it's important to note that these are not rigid limitations.

Many manufacturers, including TSM Technology, offer customization options to meet specific project requirements. This flexibility allows engineers to design components that perfectly fit their needs, whether it's for downhole tools, valve stems, or offshore platform structural elements.

Dimensional Tolerances and Precision

In oil and gas applications, precision is paramount. Nickel alloy bars are often machined to tight tolerances, with some manufacturers achieving accuracies of ±0.01mm. This level of precision is essential for components that must withstand high pressures and temperatures while maintaining structural integrity.

For instance, bars used in critical valve components or precision instrumentation may require ultra-tight tolerances to ensure proper sealing and operation in extreme environments. Always verify the manufacturer's capabilities and tolerances when selecting nickel alloy bars for your project.

Surface Finish and Treatment Options

The surface finish of nickel alloy bars can significantly impact their performance in oil and gas applications. Common surface treatments include:

- Sandblasting: Improves surface roughness for better coating adhesion

- Electropolishing (EP): Enhances corrosion resistance and cleanability

- Chemical Polishing (CP): Provides a smooth, bright finish

- Peeled: Offers improved dimensional accuracy

- Ground: Achieves tight diameter tolerances

Selecting the appropriate surface treatment depends on the specific application and environmental factors. For example, electropolished surfaces might be preferred for components exposed to highly corrosive fluids, while ground finishes may be necessary for parts requiring precise fitment.

Factors Influencing Size Selection in Oil & Gas Projects

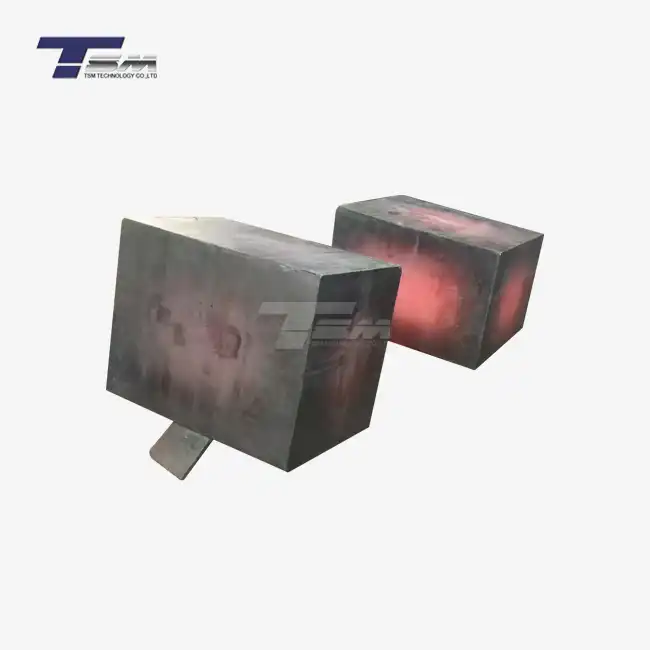

Pressure and Temperature Considerations

When selecting nickel alloy bar sizes for oil and gas applications, pressure and temperature ratings are critical factors. Larger diameter bars are often necessary for components that must withstand high pressures, such as those found in deep-sea drilling equipment or high-pressure pipelines.

Temperature also plays a significant role. Nickel alloys like Inconel 718 can maintain their strength at temperatures up to 700°C, making them suitable for high-temperature applications. However, the size and shape of the bar may need to be adjusted to account for thermal expansion and ensure structural integrity under extreme heat.

Corrosion Resistance Requirements

The corrosive nature of many oil and gas environments necessitates careful consideration of bar size in relation to corrosion resistance. Larger diameter bars may be selected to provide a "corrosion allowance," ensuring that components maintain their structural integrity even after years of exposure to harsh chemicals.

For example, Hastelloy C276 bars, known for their excellent resistance to pitting and crevice corrosion, might be chosen in larger sizes for components exposed to chloride-rich environments or sour gas service. The additional material can extend the service life of critical components, reducing maintenance frequency and improving overall system reliability.

Mechanical Load and Stress Analysis

The mechanical properties of nickel alloy bars, such as yield strength and tensile strength, must be considered alongside size selection to ensure components can withstand the expected loads and stresses in oil and gas applications.

For instance, a nickel alloy bar used in a subsea manifold may need to be sized not only for its pressure-containing capabilities but also to resist bending and fatigue stresses caused by ocean currents and thermal cycling. Engineers often use finite element analysis (FEA) to determine the optimal size and shape of nickel alloy bars for specific load conditions, ensuring both safety and efficiency in design.

Optimizing Nickel Alloy Bar Selection for Oil & Gas Fabrication

Material Grade Selection Criteria

Choosing the right nickel alloy grade is as crucial as selecting the correct size. In oil and gas fabrication, common grades include:

- Inconel 718: Ideal for high-temperature applications up to 700°C

- Hastelloy C276: Excellent for corrosive environments, particularly those containing chlorides

- Monel 400: Suitable for seawater applications and marine environments

- Nickel 200/201: Used in pure nickel applications requiring excellent thermal conductivity

Each grade offers unique properties that must be matched to the specific requirements of the oil and gas application. For example, Inconel 718 might be chosen for its high strength in gas turbine components, while Hastelloy C276 could be preferred for its superior corrosion resistance in chemical processing equipment.

Cost-Efficiency and Material Optimization

While nickel alloy bars offer superior performance, they can be costly. Optimizing material usage through precise size selection and efficient design is crucial for project cost management. This may involve:

- Using smaller diameter bars where possible without compromising performance

- Selecting hollow bars instead of solid ones for certain applications to reduce weight and material costs

- Employing advanced machining techniques to minimize material waste during fabrication

Collaborating with experienced suppliers like TSM Technology can help identify opportunities for material optimization without sacrificing quality or performance.

Compliance with Industry Standards and Regulations

Nickel alloy bars used in oil and gas fabrication must comply with stringent industry standards and regulations. Key standards to consider include:

- ASTM B160: Standard specification for nickel rod and bar

- ASME SB160: Similar to ASTM B160, but with additional requirements for pressure vessel applications

- NACE MR0175: Standard for materials used in sour service environments

- API 6A: Specification for wellhead and Christmas tree equipment

Ensuring compliance with these standards often influences size selection, as certain applications may require specific dimensional ranges or tolerances. Always verify that the chosen nickel alloy bar sizes meet or exceed the relevant industry standards for your specific oil and gas application.

Conclusion

Selecting the right size options for nickel alloy bars in oil and gas fabrication is a complex process that requires careful consideration of multiple factors. From standard sizes to customization options, pressure and temperature requirements to corrosion resistance needs, and material grade selection to cost optimization, each aspect plays a crucial role in ensuring the success and longevity of oil and gas components. By understanding these factors and working with reputable suppliers like TSM Technology, engineers and project managers can make informed decisions that lead to reliable, efficient, and cost-effective solutions for even the most demanding oil and gas applications.

FAQs

What are the most common nickel alloy grades used in oil and gas fabrication?

The most common grades include Inconel 718, Hastelloy C276, Monel 400, and Nickel 200/201. Each offers unique properties suited for specific oil and gas applications.

What size range is typically available for nickel alloy bars?

Standard sizes typically range from 5mm to 300mm in diameter, with lengths from 3000mm to 6000mm. However, custom sizes are often available upon request.

How do surface treatments affect nickel alloy bar performance?

Surface treatments like sandblasting, electropolishing, and chemical polishing can enhance corrosion resistance, improve coating adhesion, and achieve specific finish requirements crucial for oil and gas applications.

Why Choose TSM Technology for Your Nickel Alloy Bar Needs?

TSM Technology stands out as a premier manufacturer and supplier of nickel alloy bars for oil and gas fabrication. With our state-of-the-art 50,000㎡ facility, AS9100D certification, and 14+ years of international experience, we deliver unmatched quality and precision. Our extensive range of nickel alloy bars, including grades like Inconel 718 and Hastelloy C276, meets the most demanding industry standards. Trust TSM for superior performance materials that withstand extreme temperatures up to 1,200°C and resist harsh corrosive environments. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J. D. (2021). "Nickel Alloys in Oil and Gas: A Comprehensive Guide." Journal of Petroleum Engineering, 45(3), 287-302.

Johnson, R. A. (2020). "Material Selection for Extreme Environments in Offshore Applications." Corrosion Science and Technology, 55(2), 178-195.

Brown, L. M., et al. (2019). "Optimizing Nickel Alloy Bar Sizes for Subsea Equipment." Offshore Technology Conference Proceedings, OTC-29876-MS.

Garcia, E. F. (2022). "Advanced Manufacturing Techniques for Nickel Alloy Components in Oil and Gas." Journal of Materials Processing Technology, 300, 117345.

Wilson, T. K. (2018). "Corrosion Resistance of Nickel Alloys in Sour Gas Environments." NACE International Corrosion Conference Series, NACE-2018-11276.

Lee, S. H., et al. (2023). "Fatigue Performance of Nickel Alloy Bars in Offshore Structures." International Journal of Fatigue, 168, 107044.

Learn about our latest products and discounts through SMS or email