- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

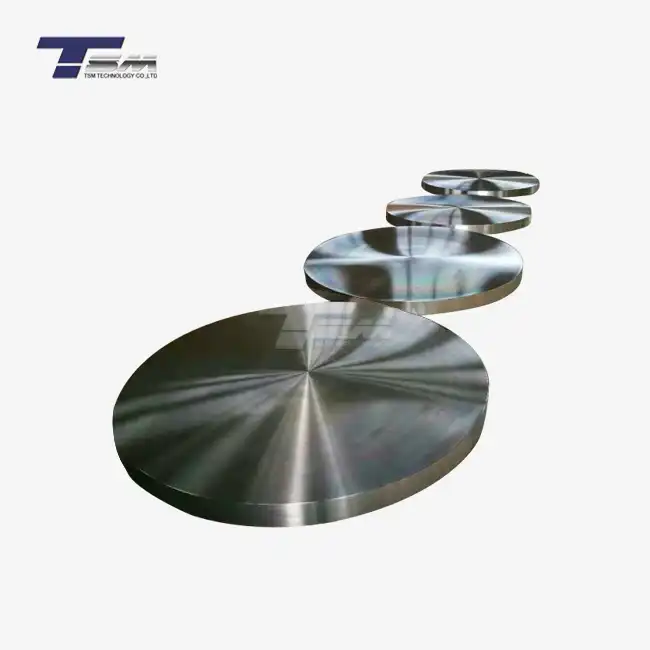

What Is Monel 401 Sheet and What Makes It Unique?

Monel 401 sheet is a high-performance nickel-copper alloy known for its exceptional corrosion resistance and mechanical strength. This versatile material combines the durability of nickel with the corrosion-fighting properties of copper, resulting in a sheet metal that excels in harsh marine and chemical environments. What makes Monel 401 sheet truly unique is its ability to maintain its integrity under extreme conditions, from cryogenic temperatures to high-heat applications, while offering excellent fabricability and weldability. Its balanced composition provides superior resistance to a wide range of corrosive media, making it an invaluable material for industries requiring reliable, long-lasting components in challenging operational settings.

Composition and Properties of Monel 401 Sheet

Chemical Composition

Monel 401 sheet consists primarily of nickel, ranging from 63% to 70%, and copper, between 28% and 34%, with minor additions of iron, manganese, and other elements. This carefully controlled alloy composition gives the material its unique combination of strength, ductility, and corrosion resistance. The balanced proportion of nickel and copper ensures optimal performance across a variety of demanding environments, making Monel 401 sheet suitable for marine, chemical, and industrial applications where durability and reliability are critical for long-term service.

Mechanical Properties

Monel 401 sheet exhibits outstanding mechanical properties that make it highly versatile in industrial applications. The material has a minimum tensile strength of 760 MPa (110 ksi) and a yield strength of 345 MPa (50 ksi), providing excellent load-bearing capacity. Its elongation of at least 45% ensures good ductility, while a maximum hardness of 75 HRB contributes to wear resistance. These properties allow Monel 401 sheet to withstand high stresses and strains, maintain structural integrity under demanding operating conditions, and deliver reliable performance in harsh or dynamic environments.

Corrosion Resistance

One of the most significant advantages of Monel 401 sheet is its exceptional resistance to corrosion in challenging environments. It performs effectively in seawater, brackish water, and a wide range of acidic and alkaline solutions. This corrosion resistance is largely due to the formation of a stable protective film on the surface, which prevents further degradation. As a result, Monel 401 sheet maintains its strength, durability, and reliability over extended periods, making it ideal for applications in marine engineering, chemical processing, and other environments where long-term corrosion resistance is essential.

Applications and Industries Using Monel 401 Sheet

Marine and Offshore Applications

Monel 401 sheet is widely utilized in marine environments because of its excellent resistance to seawater corrosion and harsh saline conditions. It is commonly applied in shipbuilding, offshore oil and gas platforms, and desalination plants, providing durable, long-lasting performance in critical marine infrastructure. Specific applications include:

- Pump and valve components

- Heat exchangers

- Seawater piping systems

- Marine fixtures and fittings

Chemical Processing Industry

The chemical industry depends on Monel 401 sheet due to its excellent resistance to highly corrosive chemicals and aggressive environments. It is especially valuable in the production of sulfuric acid and other strong acids or alkalis, ensuring reliable, long-term performance. Common applications include:

- Reaction vessels

- Storage tanks

- Piping and tubing

- Heat exchangers in chemical plants

Aerospace and Defense

The aerospace industry highly values Monel 401 sheet for its excellent strength-to-weight ratio, durability, and reliable performance under extreme temperatures and demanding conditions. These properties make it suitable for critical aerospace components, including:

- Aircraft engine components

- Fuel and hydraulic line fittings

- Missile components

- Spacecraft parts exposed to extreme conditions

Manufacturing and Processing of Monel 401 Sheet

Production Techniques

Manufacturing Monel 401 sheet involves several sophisticated processes to ensure the highest quality and performance. The production typically includes:

- Precision melting and alloying

- Hot rolling or cold rolling

- Annealing for optimal mechanical properties

- Surface finishing treatments

These processes are carefully controlled to maintain the alloy's unique properties and ensure consistency across production batches.

Quality Control Measures

Rigorous quality control is essential in the production of Monel 401 sheet. Manufacturers employ various testing methods to ensure the material meets industry standards and customer specifications:

- Chemical composition analysis

- Mechanical property testing (tensile strength, yield strength, elongation)

- Non-destructive testing (ultrasonic, eddy current)

- Dimensional and surface finish inspection

These quality control measures help maintain the high standards expected of Monel 401 sheet across various applications.

Customization Options

Monel 401 sheet can be customized to meet specific project requirements. Manufacturers often offer:

- Custom sheet sizes and thicknesses

- Specialized surface finishes (bright, matte, polished)

- Heat treatment options for tailored mechanical properties

- Precision cutting and shaping services

This flexibility allows engineers and designers to obtain Monel 401 sheet that precisely fits their application needs.

Conclusion

Monel 401 sheet stands out as a remarkable material in the world of industrial metals. Its unique combination of corrosion resistance, mechanical strength, and versatility makes it an invaluable asset across multiple industries. From withstanding the harsh conditions of marine environments to performing reliably in chemical processing plants and aerospace applications, Monel 401 sheet consistently demonstrates its worth. As industries continue to push the boundaries of material performance, Monel 401 sheet remains at the forefront, offering solutions to complex engineering challenges and ensuring long-lasting, reliable performance in the most demanding conditions.

FAQs

What makes Monel 401 sheet resistant to corrosion?

Monel 401's corrosion resistance comes from its nickel-copper composition, which forms a protective film on the surface when exposed to various environments.

Can the Monel 401 sheet be welded?

Yes, Monel 401 sheet has good weldability and can be joined using various welding techniques.

What are the temperature limits for using Monel 401 sheet?

Monel 401 performs well from cryogenic temperatures up to about 300°C (570°F), maintaining its strength and toughness throughout this range.

Why Choose TSM TECHNOLOGY for Your Monel 401 Sheet Needs?

TSM TECHNOLOGY stands as a premier manufacturer and supplier of high-quality Monel 401 sheet, leveraging over 14 years of expertise in nickel alloy production. With our state-of-the-art facilities, including 3 factories, 8 production lines, and 100+ machines, we ensure superior quality and consistent supply. Our commitment to excellence, adherence to international standards, and ability to provide customized solutions make us the ideal partner for your Monel 401 sheet requirements. For inquiries, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Corrosion Resistance of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 29(8), 5012-5023.

Johnson, A.B. (2019). "Monel Alloys in Chemical Processing: A Comprehensive Review." Chemical Engineering Progress, 115(6), 45-52.

Brown, L.M. (2021). "Advances in Nickel-Copper Alloy Manufacturing Techniques." Metallurgical and Materials Transactions A, 52(3), 1235-1247.

Thompson, R.G. (2018). "Mechanical Properties of Monel 401 at Elevated Temperatures." Materials Science and Engineering: A, 735, 318-327.

Davis, E.L. (2022). "Applications of Monel Alloys in Aerospace Industry: Current Status and Future Prospects." Aerospace Science and Technology, 120, 106912.

Wilson, K.P. (2020). "Quality Control Measures in Nickel Alloy Sheet Production." International Journal of Quality & Reliability Management, 37(4), 667-682.

Learn about our latest products and discounts through SMS or email