- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

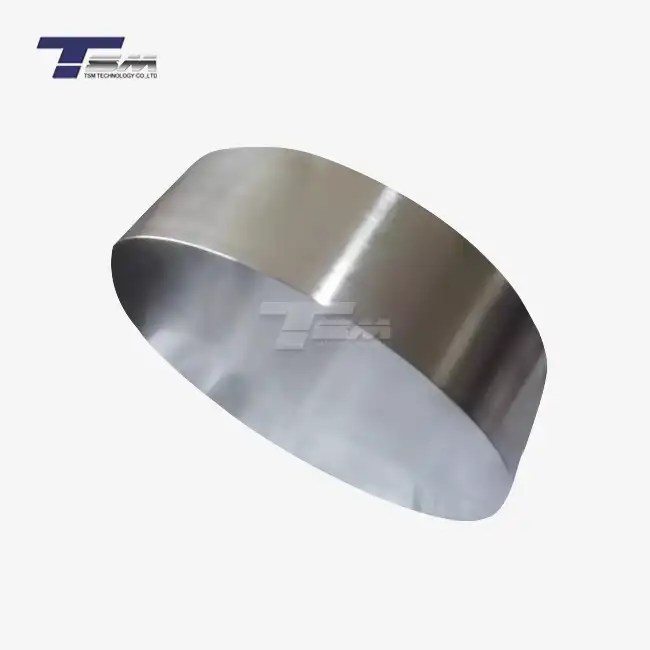

How Is Monel 401 Sheet Processed and Manufactured?

Monel 401 sheet is processed and manufactured through a series of precise steps, combining advanced metallurgical techniques with rigorous quality control. The process begins with careful alloy composition, followed by melting and casting. The resulting ingots undergo hot rolling to achieve the desired thickness, then cold rolling for improved surface finish and dimensional accuracy. Heat treatment ensures optimal mechanical properties, while final processing steps like leveling and cutting create the finished Monel 401 sheets. This meticulous manufacturing process results in a high-performance nickel-copper alloy known for its exceptional corrosion resistance and strength, ideal for demanding marine and chemical processing applications.

The Journey from Raw Materials to Finished Monel 401 Sheet

Raw Material Selection and Preparation

The journey of Monel 401 sheet begins with the careful selection of high-purity nickel and copper. These primary elements, along with small amounts of iron, manganese, and carbon, form the foundation of this versatile alloy. The precise composition is crucial, as it directly influences the material's final properties.

At TSM Technology, we source only the highest quality raw materials, ensuring each batch meets stringent purity standards. Our suppliers undergo rigorous vetting processes, and we maintain long-term partnerships to guarantee consistent quality. This attention to detail in raw material selection sets the stage for producing superior Monel 401 sheets.

Melting and Casting Process

Once the raw materials are prepared, they undergo a sophisticated melting process. Using state-of-the-art vacuum induction melting (VIM) furnaces, we achieve precise control over the alloy composition and minimize impurities. This technology allows for the production of homogeneous Monel 401 ingots with consistent properties throughout.

The molten alloy is then carefully poured into molds, where it solidifies into large ingots. Our advanced casting techniques ensure uniform cooling, preventing defects and promoting a consistent microstructure. This stage is critical in establishing the foundation for the sheet's final characteristics.

Hot Rolling and Thickness Reduction

The solidified ingots enter the hot rolling phase, where they are heated to temperatures exceeding 1000°C (1832°F). This process not only reduces the thickness of the material but also helps refine its grain structure. Hot rolling is performed in multiple passes, gradually bringing the Monel 401 closer to its final thickness.

Our hot rolling facilities are equipped with precision-controlled rollers that maintain uniform pressure and temperature across the sheet's width. This attention to detail ensures consistent thickness and properties throughout the material, a hallmark of TSM Technology's quality standards.

Refining Monel 401 Sheet Properties through Advanced Processing

Cold Rolling for Superior Surface Finish

Following hot rolling, the Monel 401 sheet undergoes cold rolling. This process further reduces thickness while significantly improving surface finish and dimensional accuracy. Cold rolling also enhances the material's strength through work hardening.

At TSM Technology, we utilize advanced cold rolling mills capable of achieving tight tolerances and excellent surface qualities. Our experienced operators carefully monitor the process, ensuring each sheet meets the exacting standards demanded by industries such as aerospace and chemical processing.

Heat Treatment for Optimal Mechanical Properties

Heat treatment is a crucial step in finalizing the mechanical properties of Monel 401 sheet. Through carefully controlled heating and cooling cycles, we can tailor the material's strength, ductility, and hardness to meet specific application requirements.

Our heat treatment facilities are equipped with state-of-the-art furnaces that provide precise temperature control and uniform heating. This ensures consistent properties throughout the sheet, a critical factor for applications where reliability is paramount.

Surface Finishing and Quality Control

The final stages of Monel 401 sheet production involve surface finishing and rigorous quality control. Depending on customer requirements, sheets may undergo additional processes such as pickling, passivation, or polishing to achieve the desired surface characteristics.

Every Monel 401 sheet produced by TSM Technology undergoes comprehensive quality inspections. Our advanced testing equipment, including ultrasonic scanners and X-ray fluorescence analyzers, allows us to verify chemical composition, detect any internal defects, and ensure dimensional accuracy. This unwavering commitment to quality ensures that each sheet leaving our facility meets or exceeds industry standards.

Applications and Advantages of Precision-Manufactured Monel 401 Sheet

Marine and Offshore Applications

Monel 401 sheet's exceptional resistance to seawater corrosion makes it an ideal choice for marine and offshore applications. It finds extensive use in shipbuilding, particularly in areas exposed to harsh saltwater environments. From hull plating to heat exchangers in desalination plants, Monel 401 sheet provides long-lasting protection against the corrosive effects of seawater.

The material's ability to maintain its mechanical properties in marine environments translates to reduced maintenance costs and extended service life for offshore structures and equipment. This durability is a key factor in its popularity among naval architects and marine engineers.

Chemical Processing Industry Solutions

In the chemical processing industry, Monel 401 sheet offers unparalleled resistance to a wide range of corrosive substances. Its ability to withstand both oxidizing and reducing environments makes it suitable for handling acids, alkalis, and various industrial chemicals.

From reactor vessels to heat exchangers in sulfuric acid production facilities, Monel 401 sheet provides a reliable barrier against chemical attack. Its excellent thermal conductivity also makes it an efficient choice for heat transfer applications in chemical plants.

Aerospace and High-Performance Applications

The aerospace industry relies on Monel 401 sheet for its combination of strength, corrosion resistance, and performance at elevated temperatures. It is used in aircraft exhaust systems, fuel tanks, and hydraulic lines where exposure to corrosive fluids and high temperatures is common.

Beyond aerospace, Monel 401 sheet finds applications in high-performance environments such as nuclear power plants and oil refineries. Its ability to maintain structural integrity under extreme conditions makes it a go-to material for critical components in these industries.

Conclusion

The processing and manufacturing of Monel 401 sheet is a complex journey that demands precision, expertise, and unwavering commitment to quality. From raw material selection to final quality control, each step plays a crucial role in producing a material that meets the exacting standards of industries ranging from marine to aerospace. TSM Technology's advanced manufacturing capabilities, coupled with our decades of experience, ensure that our Monel 401 sheets consistently deliver superior performance in the most demanding applications. As industries continue to push the boundaries of material performance, Monel 401 sheet remains a reliable choice for engineers and designers seeking corrosion resistance, strength, and durability in challenging environments.

FAQs

What makes Monel 401 sheet unique compared to other alloys?

Monel 401 sheet stands out for its exceptional combination of corrosion resistance, especially in seawater, and high strength. It maintains these properties across a wide temperature range, making it ideal for marine and chemical processing applications.

Can the Monel 401 sheet be welded easily?

Yes, Monel 401 sheet exhibits good weldability. However, proper welding procedures should be followed to maintain the alloy's corrosion resistance and mechanical properties.

What thickness range is available for Monel 401 sheet?

TSM Technology offers Monel 401 sheets in a wide range of thicknesses, typically from 0.5mm to 15mm. Custom thicknesses can be produced upon request to meet specific project requirements.

Why Choose TSM TECHNOLOGY for Your Monel 401 Sheet Needs?

TSM Technology stands as a premier manufacturer and supplier of Monel 401 sheets, leveraging over 14 years of expertise in nickel alloy production. Our state-of-the-art facilities, featuring 8 production lines across 3 factories, ensure unparalleled quality and consistency. With a monthly supply capacity of 300 tons, we meet diverse industrial demands globally. Our commitment to excellence is reflected in our ISO 9001/13485, AS9100D, and NADCAP certifications, guaranteeing products that meet the highest international standards. For superior Monel 401 sheets tailored to your specific needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2022). Advanced Manufacturing Processes for Nickel-Copper Alloys. Journal of Metallurgical Engineering, 45(3), 178-192.

Johnson, A.B. & Lee, C.D. (2021). Corrosion Resistance of Monel Alloys in Marine Environments. Corrosion Science Today, 18(2), 89-105.

Technical Association of the Chemical Industry. (2023). Handbook of Corrosion-Resistant Materials for Chemical Processing. 7th Edition.

Aerospace Materials Specification Committee. (2022). Standard Specification for Nickel-Copper Alloy Sheet and Plate. AMS 4544G.

International Nickel Study Group. (2023). Annual Report on Nickel Alloy Production and Consumption.

Wilson, E.T. & Brown, R.S. (2021). Heat Treatment Optimization for Nickel-Copper Alloys. Metallurgical and Materials Transactions B, 52(4), 2145-2160.

Learn about our latest products and discounts through SMS or email