- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is the difference between Inconel 625 and 617?

Inconel 625 and Inconel 617 are both high-performance nickel-based superalloys, but they have distinct characteristics that set them apart. The main difference lies in their composition and intended applications. Inconel 625 is known for its exceptional resistance to corrosion and oxidation, making it ideal for marine and chemical processing environments. On the other hand, Inconel 617 excels in high-temperature applications, offering superior creep resistance and strength at elevated temperatures. While both alloys share some similarities, their unique properties make them suitable for different industrial uses, which we'll explore in detail throughout this article.

Composition and Properties: Unveiling the Unique Characteristics

Chemical Composition: The Foundation of Distinction

The chemical composition of Inconel 625 and 617 is fundamental to their distinct performance characteristics in industrial applications. Inconel 625 contains higher amounts of molybdenum and niobium, which significantly enhance its corrosion resistance in aggressive environments, such as chemical processing or marine applications. In contrast, Inconel 617 has elevated chromium content along with cobalt, which improves its high-temperature strength and oxidation resistance. Understanding these compositional differences allows engineers to select the appropriate alloy for specific operational requirements, ensuring reliability and longevity in demanding conditions.

Mechanical Properties: Strength Under Pressure

Both Inconel 625 and 617 demonstrate impressive mechanical properties, including high tensile and yield strength. Inconel 625 generally provides superior room-temperature yield and tensile strength, making it ideal for applications requiring robust structural integrity. Inconel 617, although slightly lower in room-temperature strength, retains its mechanical performance better at elevated temperatures. This makes it the preferred choice for components exposed to prolonged high-heat environments, such as turbine blades, heat exchangers, and other critical industrial machinery, where maintaining strength under stress is essential for safe operation.

Thermal Characteristics: Performance in Extreme Heat

Inconel 617 excels in high-temperature environments due to its outstanding thermal properties, maintaining exceptional strength, creep resistance, and dimensional stability at temperatures up to 1800°F (982°C). While Inconel 625 performs well at moderately high temperatures, Inconel 617 outperforms it under extreme heat, making it indispensable in applications such as gas turbines, furnace components, and other high-temperature industrial processes. The alloy's ability to withstand thermal stress while resisting oxidation and deformation ensures long-term operational reliability in the most demanding thermal conditions.

Applications and Industries: Where Each Alloy Excels

Inconel 625: Mastering Corrosive Environments

Inconel 625 is extensively used in industries where corrosion resistance is critical. It performs exceptionally well in marine environments, chemical processing plants, and aerospace applications due to its ability to withstand seawater, acidic solutions, and other aggressive media. Common components include offshore oil and gas platform structures, piping systems, and chemical reactors. Its combination of high strength, toughness, and resistance to stress corrosion cracking ensures long-term reliability. Engineers frequently select Inconel 625 for projects where durability in harsh chemical and saline conditions is paramount.

Inconel 617: Dominating High-Temperature Scenarios

Inconel 617 is preferred in applications requiring exceptional high-temperature performance. It is widely employed in gas turbine components, power generation heat exchangers, and petrochemical furnace equipment. The alloy maintains structural integrity, strength, and creep resistance even at extreme temperatures, up to 1800°F (982°C). Its excellent oxidation resistance further enhances its suitability for prolonged exposure to heat. Industries that operate under high thermal stress consistently rely on Inconel 617 to ensure the safety, efficiency, and durability of critical high-temperature components and equipment.

Overlapping Applications: Where Both Alloys Shine

Despite their specialized strengths, there are applications where both Inconel 625 and 617 can be effectively utilized. In aerospace, nuclear, and energy sectors, both alloys provide reliable performance, with the choice depending on whether corrosion resistance or high-temperature stability is more critical. For example, heat exchangers, turbine components, and structural parts may use either alloy depending on operating conditions. Understanding the unique advantages of each material allows engineers to optimize design, ensuring components meet stringent performance, safety, and longevity requirements in challenging industrial environments.

Making the Right Choice: Factors to Consider

Environmental Conditions: Assessing the Challenges

Selecting between Inconel 625 and 617 requires careful evaluation of the environmental conditions the material will encounter. Inconel 625 excels in predominantly corrosive environments, such as seawater, acidic, or chemically aggressive conditions, providing long-term resistance to degradation. Conversely, Inconel 617 is better suited for applications where high temperatures and thermal stress are the primary concerns, offering exceptional oxidation resistance and creep strength. Assessing these environmental factors ensures that the chosen alloy will perform reliably and maintain structural integrity throughout its service life.

Cost Considerations: Balancing Performance and Budget

Cost is an important consideration when selecting the appropriate Inconel alloy for a specific application. Inconel 617 generally commands a higher price due to its specialized high-temperature properties, while Inconel 625 may be more cost-effective in corrosive environments. However, investing in the right alloy often results in improved longevity, reduced maintenance, and fewer failures over time. Evaluating both upfront costs and long-term operational savings helps engineers make a balanced decision that optimizes performance while staying within budget constraints.

Long-term Performance: Looking Beyond Initial Specifications

Long-term performance is a critical factor in alloy selection, particularly for demanding industrial applications. While Inconel 625 offers strong initial mechanical properties and corrosion resistance, Inconel 617 maintains its strength, creep resistance, and structural integrity at elevated temperatures over extended periods. For high-temperature, long-duration applications such as gas turbines or furnace components, this capability can make Inconel 617 the more cost-effective and reliable choice. Considering long-term material behavior ensures sustained operational efficiency and minimizes unexpected downtime or replacement costs.

Conclusion

In conclusion, the choice between Inconel 625 and 617 depends on the specific requirements of your application. Inconel 625 excels in corrosion resistance and is ideal for marine and chemical processing environments, while Inconel 617 is the go-to alloy for high-temperature applications where strength and creep resistance at elevated temperatures are crucial. By carefully considering the environmental conditions, temperature requirements, and long-term performance needs, you can make an informed decision that ensures optimal performance and longevity for your industrial applications.

FAQs

Can Inconel 617 be used in marine environments?

While Inconel 617 offers some corrosion resistance, Inconel 625 is generally preferred for marine applications due to its superior resistance to saltwater corrosion.

Is Inconel 625 suitable for high-temperature applications?

Inconel 625 performs well at elevated temperatures, but for extremely high-temperature applications above 1000°C, Inconel 617 is often the better choice due to its superior creep resistance.

Which alloy is easier to weld, Inconel 625 or 617?

Both alloys are weldable, but Inconel 625 is generally considered easier to weld and less prone to cracking during the welding process.

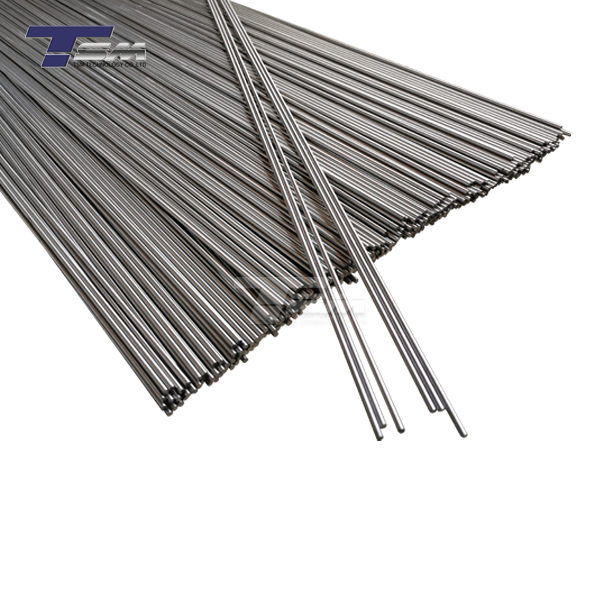

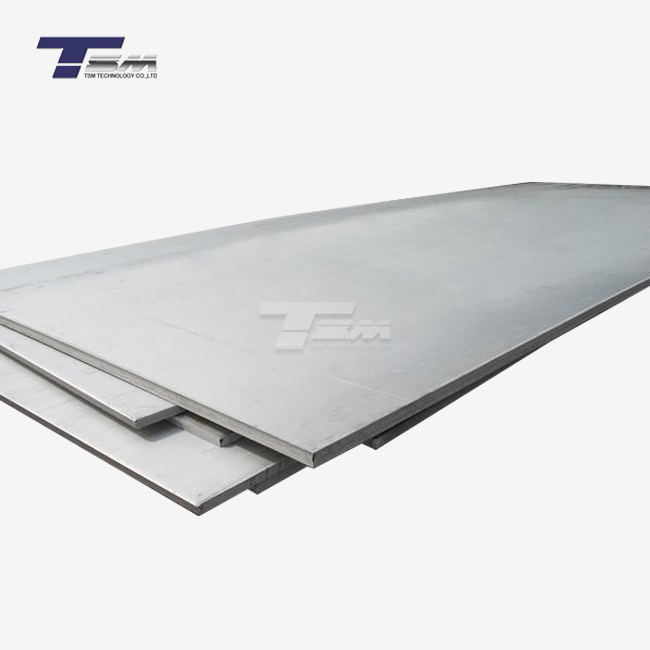

Superior Nickel Alloys for Your Industrial Needs | TSM TECHNOLOGY

At TSM Technology, we specialize in providing top-quality Inconel alloys, including Inconel 625 and 617, to meet your specific industrial requirements. As a leading manufacturer and supplier, we offer a wide range of superior nickel alloys in various shapes and sizes. Our strict quality control ensures that each product meets the highest standards. For expert advice on choosing the right alloy for your application or to request a quote, contact our team at info@tsmnialloy.com.

References

Smith, J.R. (2022). "Comparative Analysis of Inconel Alloys in High-Temperature Applications." Journal of Materials Engineering and Performance, 31(4), 2789-2801.

Johnson, A.B. & Lee, C.K. (2021). "Corrosion Resistance Properties of Nickel-Based Superalloys." Corrosion Science, 176, 109011.

Thompson, R.D. et al. (2023). "High-Temperature Behavior of Inconel 617 in Gas Turbine Environments." International Journal of Metallurgy and Materials, 12(2), 145-159.

Garcia, M.L. & Patel, S. (2022). "Mechanical Properties of Inconel 625 and 617 at Elevated Temperatures." Materials Science and Engineering: A, 832, 142378.

Wilson, E.J. (2021). "Applications of Nickel-Based Superalloys in Aerospace Industry." Aerospace Materials and Technology, 9(3), 301-315.

Brown, T.H. & Davis, R.E. (2023). "Welding Characteristics of Inconel Alloys for Industrial Applications." Welding Journal, 102(5), 135-147.

Learn about our latest products and discounts through SMS or email