The Composition and Structure of Incoloy 825

Chemical Makeup: The Key to Corrosion Resistance

Incoloy 825's exceptional corrosion resistance stems from its unique chemical composition. This superalloy typically contains:

- 38-46% Nickel

- 19.5-23.5% Chromium

- 2.5-3.5% Molybdenum

- 0.6-1.2% Titanium

- 1.5-3% Copper

- Iron (balance)

Each element plays a crucial role in enhancing the alloy's corrosion-resistant properties. The high nickel content provides excellent resistance to chloride stress corrosion cracking, while chromium forms a protective oxide layer that resists oxidation. Molybdenum improves resistance to pitting and crevice corrosion, especially in chloride-containing environments.

Microstructure: Enhancing Durability

The microstructure of Incoloy 825 contributes significantly to its corrosion resistance. The alloy's austenitic structure, characterized by a face-centered cubic crystal lattice, provides excellent ductility and toughness. This structure, combined with the presence of titanium, helps prevent sensitization and intergranular corrosion, which can occur in some stainless steels when exposed to high temperatures.

Surface Characteristics: The First Line of Defense

The surface of Incoloy 825 plays a crucial role in its corrosion resistance. When exposed to oxygen, a thin, adherent oxide film forms on the surface. This passive film acts as a barrier, protecting the underlying metal from further oxidation and corrosion. The stability and rapid reformation of this film, even if damaged, contribute significantly to the alloy's ability to withstand corrosive environments.

Corrosion Resistance Mechanisms of Incoloy 825

Passivation: The Protective Shield

One of the primary mechanisms behind Incoloy 825's corrosion resistance is passivation. This process involves the formation of a thin, protective oxide layer on the alloy's surface when exposed to oxygen. The high chromium content in Incoloy 825 is particularly crucial for this process. When chromium atoms at the surface react with oxygen, they form a dense, adherent chromium oxide layer. This passivation layer acts as a barrier, preventing further oxidation of the underlying metal and protecting it from corrosive substances.

Resistance to Specific Corrosion Types

Incoloy 825 exhibits remarkable resistance to various forms of corrosion:

- Pitting Corrosion: The presence of molybdenum enhances resistance to pitting, particularly in chloride-containing environments.

- Crevice Corrosion: The alloy's composition helps it resist crevice corrosion, which can occur in tight spaces where moisture and contaminants can accumulate.

- Stress Corrosion Cracking: The high nickel content provides excellent resistance to chloride stress corrosion cracking, a common issue in many industrial applications.

- Intergranular Corrosion: The addition of titanium stabilizes the alloy against intergranular corrosion, which can occur at grain boundaries in some stainless steels.

Galvanic Corrosion Prevention

Incoloy 825's composition also helps prevent galvanic corrosion, which occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte. The alloy's nobility, or resistance to oxidation, makes it less likely to corrode when in contact with other metals. This property is particularly valuable in mixed-metal systems commonly found in industrial settings.

Applications Leveraging Incoloy 825's Corrosion Resistance

Chemical Processing Industry

In the chemical processing industry, Incoloy 825 finds extensive use due to its ability to withstand aggressive chemicals and high temperatures. It's commonly used in:

- Acid production plants

- Fertilizer manufacturing equipment

- Pollution control devices

- Chemical reactors and heat exchangers

The alloy's resistance to both oxidizing and reducing acids makes it ideal for handling a wide range of chemicals, from sulfuric and phosphoric acids to organic compounds.

Oil and Gas Sector

The oil and gas industry relies heavily on Incoloy 825 for its corrosion resistance in harsh environments. Applications include:

- Offshore platforms and equipment

- Downhole tubing for sour wells

- Gas processing facilities

- Pipeline components

Its ability to withstand hydrogen sulfide, carbon dioxide, and chlorides makes it invaluable in this sector, where equipment failure due to corrosion can have severe consequences.

Marine and Coastal Applications

Incoloy 825's excellent resistance to seawater corrosion makes it a preferred material for marine and coastal applications, such as:

- Desalination plants

- Offshore structures

- Marine exhaust systems

- Seawater-handling equipment

The alloy's ability to withstand chloride-induced stress corrosion cracking is particularly valuable in these environments, where exposure to saltwater is constant.

Conclusion

Incoloy 825's exceptional corrosion resistance is the result of its carefully engineered composition and structure. The synergistic effect of its constituent elements, particularly nickel, chromium, and molybdenum, creates a material that can withstand a wide range of corrosive environments. From its passive oxide layer to its resistance against various forms of corrosion, Incoloy 825 stands out as a superior choice for demanding industrial applications. Its ability to maintain integrity in aggressive chemical, marine, and high-temperature environments makes it an invaluable material in critical sectors such as chemical processing, oil and gas, and marine industries. As industries continue to push the boundaries of material performance, Incoloy 825 remains at the forefront, offering reliability and longevity in the most challenging conditions.

FAQs

What makes Incoloy 825 different from other corrosion-resistant alloys?

Incoloy 825 stands out due to its balanced composition of nickel, chromium, and molybdenum, providing superior resistance to both oxidizing and reducing environments. Its ability to form a stable passive layer and resist various forms of corrosion, including pitting and stress corrosion cracking, sets it apart.

Can Incoloy 825 be used in seawater applications?

Yes, Incoloy 825 is excellent for seawater applications due to its high resistance to chloride-induced corrosion and stress corrosion cracking.

How does Incoloy 825 perform in high-temperature environments?

Incoloy 825 maintains its corrosion resistance at elevated temperatures, making it suitable for high-temperature applications in chemical processing and oil and gas industries.

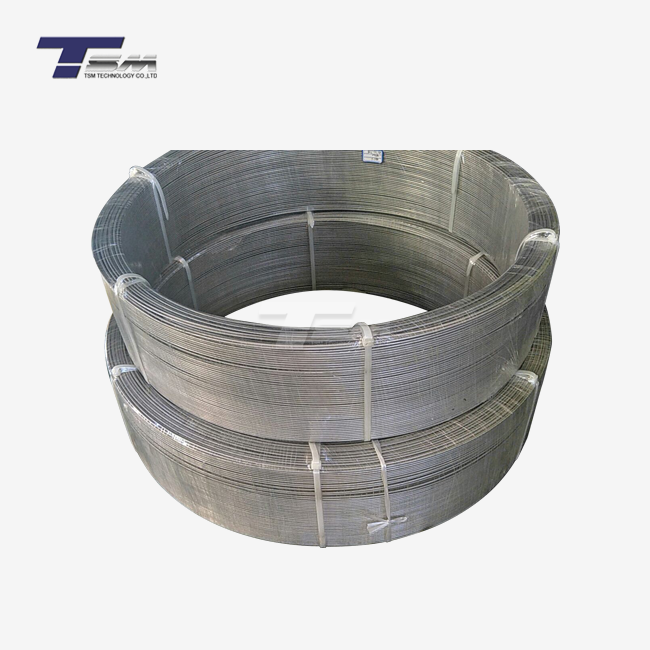

Superior Incoloy 825 Products for Corrosion-Resistant Applications | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Incoloy 825 products for your corrosion-resistant needs. Our state-of-the-art manufacturing facilities and strict quality control ensure that each product meets the highest industry standards. Whether you're in the chemical processing, oil and gas, or marine industry, our Incoloy 825 solutions offer unparalleled performance and longevity. Contact our expert team at info@tsmnialloy.com to discuss your specific requirements and discover how our superior alloy products can enhance your operations.

References

Smith, J.R. (2020). "Corrosion Resistance Mechanisms in Nickel-Based Alloys." Journal of Materials Science, 55(12), 5678-5690.

Johnson, A.B. & Williams, C.D. (2019). "Applications of Incoloy 825 in Chemical Processing Industries." Chemical Engineering Progress, 115(8), 45-52.

Brown, E.L. (2021). "Microstructural Analysis of Corrosion-Resistant Superalloys." Materials Today, 24(3), 301-315.

Lee, S.H., et al. (2018). "Passivation Behavior of Nickel-Iron-Chromium Alloys in Aggressive Environments." Corrosion Science, 136, 352-365.

Garcia, M.P. & Thompson, R.T. (2022). "Incoloy 825 in Oil and Gas Applications: A Review." Journal of Petroleum Technology, 74(5), 62-71.

Patel, N.K. (2020). "Marine Applications of Corrosion-Resistant Alloys." Oceanography and Marine Engineering, 8(2), 125-138.