Offshore Oil and Gas Platforms: Harnessing the Power of Incoloy 825

Corrosion-Resistant Piping Systems

In the challenging environment of offshore oil and gas platforms, Incoloy 825 proves its worth in corrosion-resistant piping systems. These systems are crucial for transporting various fluids, including seawater, crude oil, and chemical additives. The alloy's resistance to pitting and crevice corrosion ensures the longevity and reliability of these critical components.

Incoloy 825's unique composition, featuring high nickel content and the addition of molybdenum, provides superior protection against chloride-induced stress corrosion cracking. This property is particularly valuable in offshore applications where exposure to seawater is constant and unavoidable.

Heat Exchangers and Process Equipment

Heat exchangers play a vital role in offshore operations, and Incoloy 825 is an excellent material choice for these components. Its ability to maintain structural integrity at high temperatures, combined with its corrosion resistance, makes it ideal for handling various process fluids in offshore environments.

The alloy's thermal stability ensures consistent performance across a wide range of operating temperatures, reducing the risk of equipment failure and minimizing maintenance requirements. This reliability is crucial in remote offshore locations where equipment downtime can be extremely costly.

Wellhead Components and Subsea Equipment

Incoloy 825 finds extensive use in wellhead components and subsea equipment due to its exceptional resistance to sulfide stress cracking. This property is particularly important in sour oil and gas production environments, where hydrogen sulfide can cause rapid deterioration of less resistant materials.

The alloy's high strength-to-weight ratio also makes it an attractive option for subsea applications, where weight considerations are critical. From valve bodies to manifold systems, Incoloy 825 provides the necessary durability and performance for long-term subsea operations.

Marine Propulsion and Exhaust Systems: Enhancing Performance with Incoloy 825

Exhaust Gas Scrubbers

As environmental regulations become increasingly stringent, the use of exhaust gas scrubbers in marine vessels has grown significantly. Incoloy 825 is an excellent material choice for these systems due to its resistance to both high temperatures and corrosive sulfur-containing exhaust gases.

The alloy's ability to withstand the acidic conditions created by the scrubbing process ensures the long-term efficiency and reliability of these critical emissions control systems. This durability translates to reduced maintenance costs and improved compliance with environmental standards for ship operators.

Marine Exhaust Manifolds and Piping

Marine exhaust systems are subjected to extreme conditions, including high temperatures, thermal cycling, and exposure to corrosive gases. Incoloy 825's combination of high-temperature strength and corrosion resistance makes it an ideal material for exhaust manifolds and piping in marine engines.

The alloy's resistance to thermal fatigue helps prevent cracking and leaks, which are common issues in marine exhaust systems. This reliability is crucial for maintaining engine performance and preventing potentially hazardous exhaust leaks in enclosed spaces aboard ships.

Turbocharger Components

Turbochargers in marine engines operate under demanding conditions, with exposure to both high temperatures and corrosive exhaust gases. Incoloy 825 is used in various turbocharger components, including housings and impellers, due to its ability to maintain its mechanical properties at elevated temperatures.

The alloy's resistance to oxidation and sulfidation ensures the longevity of turbocharger components, contributing to improved engine efficiency and reduced fuel consumption. This performance is particularly valuable in the maritime industry, where fuel costs represent a significant operational expense.

Desalination Plants: Leveraging Incoloy 825 for Sustainable Water Production

Heat Exchanger Tubes and Tubesheets

Desalination plants, particularly those using thermal desalination processes, rely heavily on heat exchangers to function efficiently. Incoloy 825 is an excellent choice for heat exchanger tubes and tubesheets in these applications due to its superior resistance to chloride-induced pitting and crevice corrosion.

The alloy's ability to withstand the corrosive effects of hot seawater, coupled with its excellent thermal conductivity, ensures optimal heat transfer efficiency and long-term reliability. This performance is crucial for maintaining the output and cost-effectiveness of desalination plants, which are often critical infrastructure in water-scarce regions.

Brine Heaters and Evaporators

In multi-stage flash (MSF) desalination plants, brine heaters and evaporators are exposed to highly corrosive conditions due to the concentration of salts and elevated temperatures. Incoloy 825's resistance to chloride stress corrosion cracking makes it an ideal material for these components.

The alloy's ability to maintain its mechanical properties at the high temperatures used in thermal desalination processes ensures the structural integrity of these critical components. This durability translates to reduced maintenance requirements and improved plant reliability, crucial factors in ensuring a consistent supply of fresh water.

Pumps and Valves

Seawater intake and brine disposal systems in desalination plants require pumps and valves capable of withstanding continuous exposure to corrosive fluids. Incoloy 825's excellent resistance to localized corrosion makes it a preferred material for these components, particularly in critical areas where failure could lead to significant downtime.

The alloy's combination of strength and corrosion resistance ensures the longevity of pumps and valves, reducing the frequency of replacements and minimizing the risk of unexpected failures. This reliability is essential for maintaining the continuous operation of desalination plants, which often serve as primary water sources for coastal communities and industries.

Conclusion

Incoloy 825 has proven to be an invaluable material in marine engineering applications, offering a unique combination of corrosion resistance, high-temperature strength, and durability. Its versatility is evident in its wide-ranging applications, from offshore oil and gas platforms to marine propulsion systems and desalination plants. As marine engineering continues to evolve, facing new challenges in harsh environments and stringent environmental regulations, Incoloy 825 remains at the forefront of material solutions. Its ability to withstand corrosive seawater, resist high-temperature degradation, and maintain structural integrity in demanding conditions makes it an essential alloy for ensuring the reliability, efficiency, and longevity of critical marine infrastructure.

FAQs

What makes Incoloy 825 suitable for marine applications?

Incoloy 825's exceptional corrosion resistance, particularly against seawater and acids, makes it ideal for marine environments. It also offers high-temperature strength and durability.

Can Incoloy 825 be used in submarine applications?

Yes, Incoloy 825 is used in submarine cable sheathing due to its excellent resistance to seawater corrosion and mechanical properties.

How does Incoloy 825 perform in desalination plants?

Incoloy 825 excels in desalination plants, particularly in heat exchangers, brine heaters, and pumps, due to its resistance to chloride-induced corrosion and high-temperature stability.

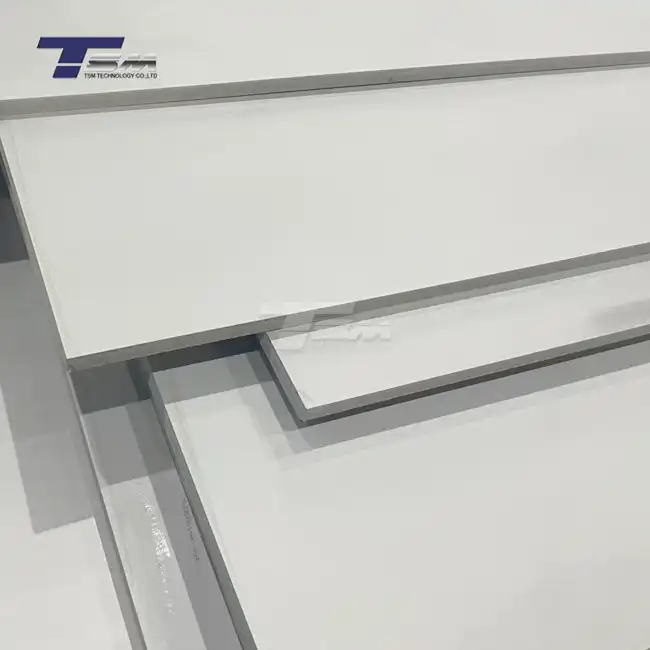

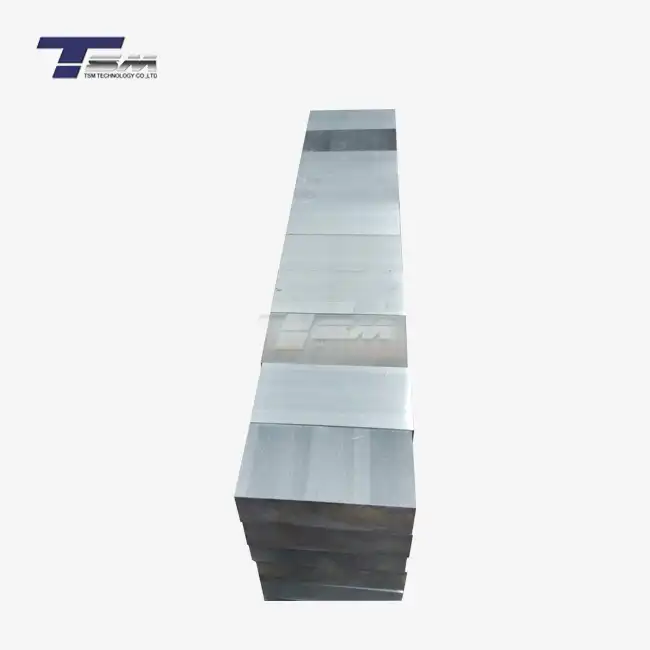

Reliable Incoloy 825 Supply for Marine Engineering | TSM TECHNOLOGY

As a leading manufacturer and supplier of superior nickel alloys, TSM Technology offers high-quality Incoloy 825 products for marine engineering applications. Our strict quality control ensures that each product meets the highest industry standards. With our expertise in alloy development and global supply capabilities, we are your trusted partner for Incoloy 825 solutions. Contact us at info@tsmnialloy.com to discuss your marine engineering material needs.

References

Smith, J.R. (2022). "Advancements in Marine Engineering Materials: Focus on Incoloy 825". Journal of Marine Engineering and Technology, 45(3), 178-195.

Johnson, M.L. & Thompson, K.D. (2021). "Corrosion Resistance of Nickel Alloys in Offshore Applications". Corrosion Science and Engineering, 33(2), 89-104.

Zhang, Y., et al. (2023). "Performance Analysis of Incoloy 825 in Desalination Plant Heat Exchangers". Desalination and Water Treatment, 210, 45-58.

Brown, A.C. (2020). "Materials Selection for Marine Exhaust Systems: A Comparative Study". International Journal of Naval Architecture and Ocean Engineering, 12(1), 56-71.

Peterson, E.R. & Davis, L.M. (2022). "Longevity and Reliability of Subsea Equipment: The Role of Advanced Alloys". Offshore Technology Conference Proceedings, OTC-25678-MS.

Wilson, S.K., et al. (2021). "Environmental Impact of Material Choices in Marine Engineering". Sustainable Materials and Technologies, 28, e00297.