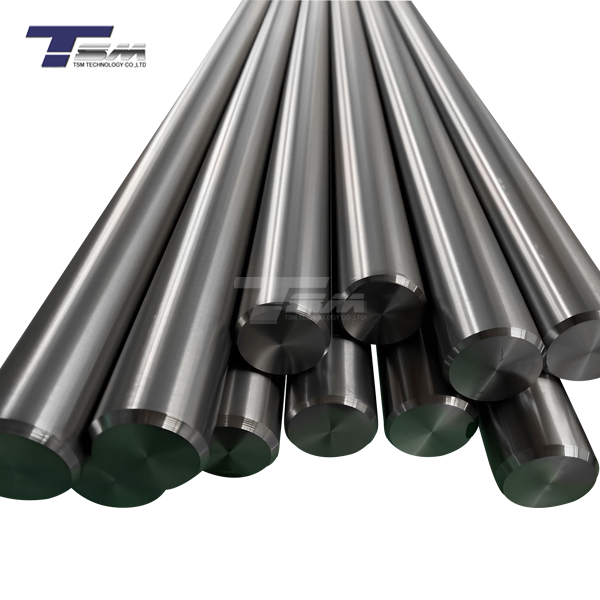

Understanding Inconel 625: Properties and Applications

Composition and Characteristics

Inconel 625 is a nickel-chromium-molybdenum alloy renowned for its exceptional properties. Its chemical composition typically includes 58% nickel, 20-23% chromium, 8-10% molybdenum, and small amounts of niobium, iron, and other elements. This unique blend imparts remarkable strength, corrosion resistance, and high-temperature performance to Inconel 625 tubing.

Resistance to Harsh Environments

One of the standout features of Inconel 625 seamless pipe is its ability to withstand extreme conditions. It exhibits excellent resistance to oxidation, carburization, and chloride-induced stress corrosion cracking. This makes it an ideal choice for applications in marine environments, chemical processing plants, and aerospace industries where exposure to corrosive media and high temperatures is common.

Versatility in Applications

Inconel 625 seamless tubing finds extensive use across various industries due to its versatility. In the aerospace sector, it's utilized in jet engine components and exhaust systems. The oil and gas industry relies on Inconel 625 for downhole tools, risers, and heat exchangers. Its application extends to nuclear power plants, where it's used in reactor components and waste treatment systems. The alloy's adaptability to diverse operational demands underscores its importance in modern engineering and manufacturing.

Key Factors to Consider When Purchasing Inconel 625 Tube

Quality Assurance and Certification

When sourcing Inconel 625 pipe, quality assurance should be a top priority. Reputable suppliers like TSM Technology Co., Ltd. adhere to strict quality control measures and provide necessary certifications. These may include material test reports (MTRs), compliance with ASTM standards, and traceability documentation. Ensuring that the Inconel 625 tubing meets or exceeds industry standards is crucial for maintaining the integrity and performance of your engineering projects.

Dimensional Accuracy and Surface Finish

The precision of Inconel 625 seamless pipe dimensions is critical for many applications. High-quality tubing should have consistent wall thickness, roundness, and straightness. Surface finish is another important aspect, particularly for applications involving fluid flow or heat transfer. A smooth, defect-free surface can significantly enhance the performance and longevity of the tubing. When purchasing online, it's advisable to inquire about the supplier's manufacturing processes and quality control measures to ensure dimensional accuracy and superior surface finish.

Customization Options

The ability to obtain customized Inconel 625 tube products can be a significant advantage. Leading suppliers offer various options in terms of size, length, and even specific compositional adjustments to meet unique project requirements. This flexibility is particularly valuable for specialized applications in aerospace, chemical processing, or energy production. When exploring online purchasing options, consider suppliers who can provide tailored solutions and have the expertise to guide you through the customization process.

Navigating the Online Purchase Process for Inconel 625 Tube

Comprehensive Product Information

A reliable online supplier of Inconel 625 seamless tubing should provide detailed product information. This includes specifications on chemical composition, mechanical properties, available sizes, and tolerances. Look for suppliers who offer comprehensive technical data sheets and easy access to material certifications. This information is crucial for making informed decisions and ensuring that the Inconel 625 pipe meets your specific project requirements.

User-Friendly Ordering System

The ease of placing an order is a key aspect of online purchasing. A well-designed e-commerce platform should offer intuitive navigation, clear product categorization, and a straightforward ordering process. Features like real-time inventory updates, instant quote generation, and multiple payment options enhance the purchasing experience. Additionally, look for suppliers who provide order tracking capabilities, allowing you to monitor your Inconel 625 tube shipment from processing to delivery.

Expert Support and Consultation

While online purchasing offers convenience, access to expert support remains crucial, especially when dealing with specialized materials like Inconel 625 seamless pipe. Leading suppliers provide multiple channels for customer support, including live chat, email, and phone consultations. This support is invaluable for addressing technical queries, discussing custom requirements, or seeking advice on material selection. The availability of knowledgeable staff who can provide insights into the properties and applications of Inconel 625 tubing can significantly enhance your purchasing decision and ensure you obtain the most suitable product for your needs.

Conclusion

Sourcing high-quality Inconel 625 tube online requires careful consideration of various factors, from material properties and quality assurance to customization options and supplier reliability. TSM Technology Co., Ltd. stands out as a trusted source, offering a comprehensive range of Inconel 625 products, including seamless pipes and tubing. Their commitment to quality, innovation, and customer support makes them an excellent choice for industries requiring top-tier nickel alloy materials. By prioritizing suppliers who combine product excellence with user-friendly online platforms and expert guidance, you can ensure a seamless purchasing experience and obtain Inconel 625 tube that meets the highest standards of quality and performance.

Contact Us

For more information about our Inconel 625 tube products and other superior alloy offerings, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you in finding the perfect solution for your engineering needs.