Raw Material Preparation and Melting Process

Selection of High-Quality Alloy Components

The process of creating Inconel 625 tubes begins with carefully selecting raw materials. Manufacturers obtain high-quality nickel, chromium, molybdenum, and other essential alloying elements to ensure the final product’s performance. Every material is subjected to stringent testing to confirm its composition and quality, as even the smallest impurities can drastically influence the alloy's properties. This thorough approach ensures that the Inconel 625 pipe meets the highest standards of durability, heat resistance, and overall strength, making it suitable for demanding applications in industries such as aerospace, chemical processing, and power generation. Quality control remains a top priority throughout.

Vacuum Induction Melting (VIM)

Once the raw materials are approved, they are combined in precise proportions and melted using the Vacuum Induction Melting (VIM) process. This sophisticated technique involves heating the alloy components in a vacuum environment, which prevents oxidation and ensures the removal of volatile impurities. The VIM process is crucial for achieving the desired chemical homogeneity and cleanliness in the Inconel 625 alloy.

Secondary Refining Techniques

After the initial melting, secondary refining techniques may be employed to further enhance the alloy's purity and properties. These may include Electroslag Remelting (ESR) or Vacuum Arc Remelting (VAR), which help eliminate residual gases, reduce segregation, and improve the overall microstructure of the alloy. The refined Inconel 625 ingot is then ready for the next stage of the manufacturing process.

Forming and Shaping Inconel 625 into Tubular Structures

Extrusion and Hot Working

The solidified Inconel 625 ingot undergoes hot working processes to transform it into a tubular shape. Extrusion is a common method used to create the initial tube form. The ingot is heated to a high temperature and forced through a die with the desired cross-sectional shape. This process not only forms the tube but also helps refine the grain structure of the alloy, enhancing its mechanical properties.

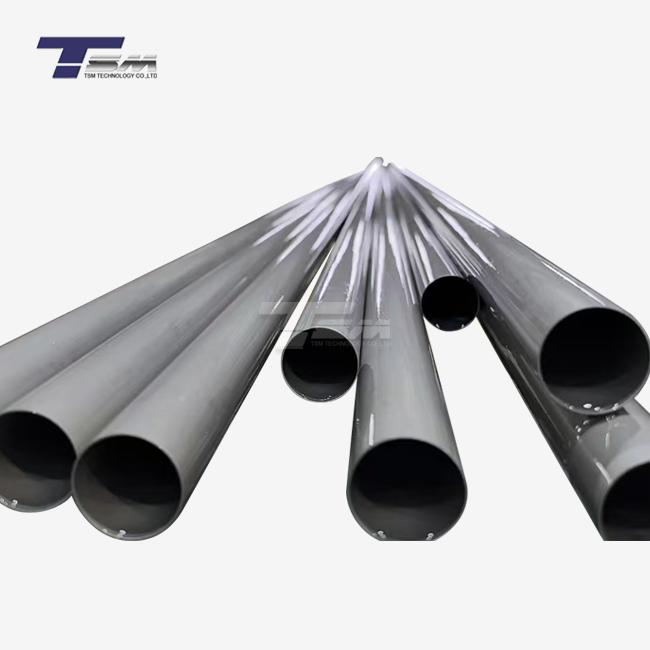

Seamless Tube Production

For Inconel 625 seamless pipe production, manufacturers often employ the pilger rolling process. This technique involves repeatedly passing a hollow billet through rotating rolls, gradually reducing the wall thickness and increasing the length. The result is a seamless tube with excellent dimensional accuracy and uniform properties throughout its length. The seamless nature of these tubes makes them particularly suitable for high-pressure and high-temperature applications.

Welded Tube Fabrication

While seamless tubes are preferred for many critical applications, welded Inconel 625 tubes are also produced for certain uses. The welding process typically involves forming a flat strip of Inconel 625 into a cylindrical shape and joining the edges using advanced welding techniques such as TIG (Tungsten Inert Gas) welding. Post-weld heat treatment is crucial to ensure the weld zone's properties match those of the base material.

Heat Treatment and Quality Control Measures

Solution Annealing

After forming, Inconel 625 tubes undergo a critical heat treatment process known as solution annealing. This involves heating the tubes to temperatures typically ranging from 1800°F to 2000°F (982°C to 1093°C) and then rapidly cooling them. This process dissolves precipitates, homogenizes the microstructure, and relieves internal stresses, resulting in optimal mechanical properties and corrosion resistance.

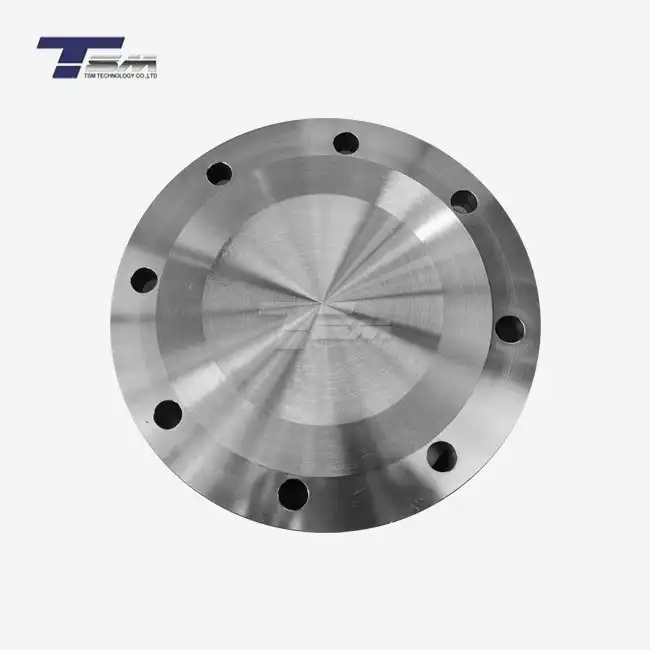

Non-Destructive Testing (NDT)

Quality control is paramount in the production of Inconel 625 tubing. Manufacturers employ various non-destructive testing methods to ensure the integrity of each tube. These may include ultrasonic testing to detect internal flaws, eddy current testing for surface defects, and hydrostatic pressure testing to verify the tube's ability to withstand high pressures. Each Inconel 625 seamless tubing undergoes rigorous inspection to meet industry standards and customer specifications.

Dimensional and Surface Finishing

The final stages of manufacturing involve precise dimensional checks and surface finishing. Tubes are measured for outer diameter, wall thickness, and straightness to ensure they meet tight tolerances. Surface finishing processes may include pickling to remove any surface oxides, polishing to achieve the required surface roughness, and marking for traceability. These steps are crucial for ensuring that the Inconel 625 pipe meets the exacting requirements of its intended applications.

Conclusion

The manufacturing process of Inconel 625 tube is a testament to the advanced metallurgical and engineering capabilities in the field of superalloys. From the careful selection of raw materials to the final quality control measures, each step is designed to produce tubing that can withstand the most challenging environments. The resulting Inconel 625 seamless pipe and welded tubing offer exceptional corrosion resistance, high-temperature strength, and reliability, making them indispensable in industries such as aerospace, chemical processing, and oil and gas. As technology advances, manufacturers continue to refine these processes, pushing the boundaries of what's possible with Inconel 625 and other high-performance alloys.

Contact Us

For more information about our Inconel 625 tube products and other superior alloys, please don't hesitate to contact us at info@tsmnialloy.com. Our team of experts is ready to help you find the perfect solution for your specific needs.