- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Where to Buy Nickel 201 Tubes - Suppliers & Pricing

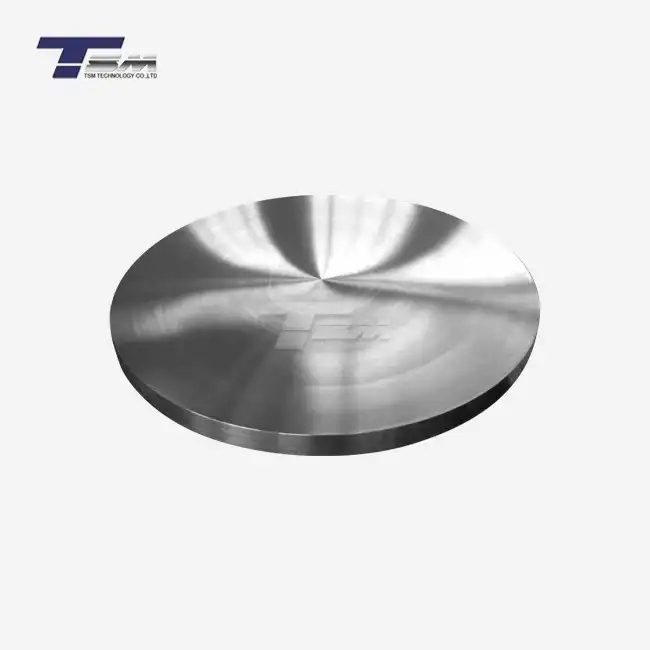

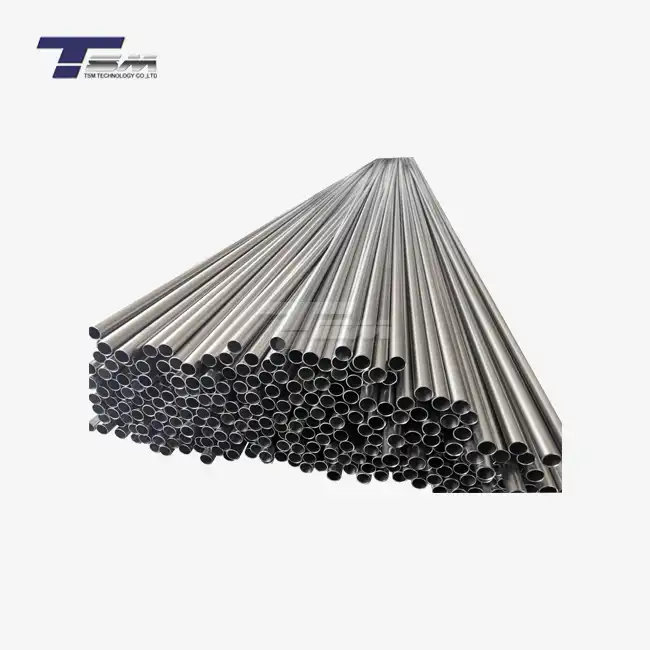

Nickel 201 is a versatile alloy known for its excellent corrosion resistance and thermal properties, making it ideal for various industrial applications. When it comes to purchasing Nickel 201 tubes, it's crucial to find reputable suppliers who offer competitive pricing without compromising on quality. In this comprehensive guide, we'll explore the best sources for Nickel 201 tubing, factors affecting pricing, and tips for ensuring you get the best value for your investment. Whether you're in the chemical processing, aerospace, or marine industry, understanding where to buy Nickel 201 tubes and how to evaluate suppliers will help you make informed decisions for your projects.

Understanding Nickel 201 Tubes and Their Applications

Composition and Properties of Nickel 201

Nickel 201 is a commercially pure nickel alloy, containing approximately 99.5% nickel. This high nickel content gives the alloy its exceptional resistance to corrosion, particularly in reducing environments. Nickel 201 tubes exhibit remarkable mechanical properties, including high ductility and malleability, making them suitable for fabrication into various shapes and components.

The alloy's low carbon content (maximum 0.02%) enhances its weldability and reduces the risk of intergranular corrosion. This characteristic is particularly valuable in applications where the material is exposed to high temperatures or corrosive environments. Nickel 201 also maintains its strength and toughness over a wide temperature range, from cryogenic conditions to elevated temperatures up to 600°C (1112°F).

Key Industries and Applications

Nickel 201 tubes find extensive use across several industries due to their unique combination of properties. In the chemical processing industry, these tubes are often employed in the construction of heat exchangers, condensers, and reaction vessels. The alloy's resistance to caustic alkalis and organic compounds makes it an excellent choice for handling corrosive fluids.

The food processing and pharmaceutical industries also benefit from Nickel 201 tubing. Its non-contaminating nature and ease of cleaning make it ideal for equipment used in the production of food, beverages, and medicines. In aerospace applications, Nickel 201 tubes are utilized in fuel systems and hydraulic lines, where their resistance to high temperatures and corrosive fluids is crucial.

Advantages of Nickel 201 Over Other Alloys

Compared to other nickel-based alloys, Nickel 201 offers several distinct advantages. Its high purity results in superior corrosion resistance, particularly in reducing environments where other alloys might falter. The material's excellent thermal conductivity makes it an optimal choice for heat transfer applications, outperforming many stainless steel grades in this aspect.

Nickel 201 also exhibits exceptional formability and weldability, allowing for complex fabrications without compromising the material's integrity. This characteristic is particularly valuable in custom-designed systems or when retrofitting existing equipment. Additionally, the alloy's resistance to hydrogen embrittlement makes it suitable for applications involving hydrogen gas or where hydrogen can be generated as a byproduct of chemical reactions.

Factors Influencing Nickel 201 Tube Pricing

Raw Material Costs and Market Trends

The price of Nickel 201 tubes is significantly influenced by the cost of raw nickel, which can be volatile due to global market dynamics. Nickel prices are subject to fluctuations based on supply and demand, geopolitical factors, and economic conditions. As Nickel 201 contains a high percentage of pure nickel, any changes in the metal's market price directly impact the cost of the finished tubes.

Additionally, the availability of high-purity nickel suitable for Nickel 201 production can affect pricing. Increased demand from emerging technologies, such as electric vehicle batteries, can drive up the cost of nickel, consequently affecting the price of Nickel 201 tubes. Savvy buyers often monitor nickel market trends to time their purchases advantageously.

Manufacturing Processes and Quality Control

The manufacturing process for Nickel 201 tubes involves several stages, each contributing to the final cost. The initial melting and alloying process requires precise control to achieve the desired composition. Subsequent forming, heat treatment, and finishing operations add to the production expenses. Advanced manufacturing techniques, such as seamless tube extrusion or welded tube fabrication with stringent quality controls, can increase the overall cost but often result in superior product quality.

Quality control measures, including non-destructive testing, chemical analysis, and mechanical property verification, are crucial in ensuring the tubes meet industry standards and customer specifications. These rigorous quality assurance processes, while adding to the cost, are essential for maintaining the integrity and reliability of Nickel 201 tubes in critical applications.

Supply Chain and Logistics Considerations

The global nature of the Nickel 201 tube market means that supply chain and logistics play a significant role in pricing. Factors such as transportation costs, import/export regulations, and tariffs can impact the final price of the tubes. The location of the manufacturer relative to the end-user can influence shipping costs and lead times, potentially affecting the overall project timeline and budget.

Furthermore, inventory management strategies adopted by suppliers can influence pricing. Some suppliers may offer competitive prices on stock items, while custom or non-standard sizes might come at a premium due to additional processing or lower production volumes. Understanding these supply chain dynamics can help buyers negotiate better terms and secure more favorable pricing for their Nickel 201 tube requirements.

Selecting the Right Nickel 201 Tube Supplier

Evaluating Supplier Credentials and Certifications

When searching for a reliable Nickel 201 tube supplier, it's crucial to evaluate their credentials and certifications. Look for suppliers who hold relevant industry certifications such as ISO 9001 for quality management systems. Certifications specific to the manufacturing of nickel alloys, like those from NACE (National Association of Corrosion Engineers) or ASME (American Society of Mechanical Engineers), can provide additional assurance of a supplier's expertise and product quality.

Investigate the supplier's track record in the industry. How long have they been in business? Do they have experience supplying Nickel 201 tubes to your specific industry? Ask for references or case studies that demonstrate their capability to meet the exacting standards required for Nickel 201 tubing. A reputable supplier should be transparent about their manufacturing processes, quality control procedures, and material traceability systems.

Comparing Pricing Strategies and Value-Added Services

While price is an important factor, it shouldn't be the sole criterion for selecting a Nickel 201 tube supplier. Compare pricing strategies among different suppliers, but also consider the value-added services they offer. Some suppliers may provide technical consultation, custom cutting and fabrication services, or expedited delivery options that can add significant value to your purchase.

Evaluate the supplier's inventory management capabilities. A supplier with a robust stock of standard sizes can offer quicker delivery times and potentially lower prices due to economies of scale. For custom requirements, assess the supplier's flexibility in producing non-standard sizes or specifications. Some suppliers might offer volume discounts or long-term contract pricing, which can be advantageous for projects with ongoing material needs.

Assessing Technical Support and Customer Service

The level of technical support and customer service provided by a Nickel 201 tube supplier can greatly impact your project's success. Look for suppliers who offer comprehensive technical documentation, including material test reports, compliance certificates, and detailed product specifications. A supplier with a knowledgeable technical team can provide valuable insights on material selection, fabrication techniques, and application-specific recommendations.

Consider the supplier's responsiveness to inquiries and their ability to provide timely quotes and order updates. Efficient customer service can streamline your procurement process and help avoid costly delays. Some suppliers may offer online ordering systems or dedicated account managers for larger clients, enhancing the overall purchasing experience. By carefully evaluating these aspects, you can select a Nickel 201 tube supplier that not only meets your immediate needs but also becomes a trusted partner for future projects.

Conclusion

Selecting the right supplier for Nickel 201 tubes is crucial for ensuring the success of your projects and maintaining the integrity of your industrial applications. By understanding the unique properties of Nickel 201, the factors influencing its pricing, and the key considerations in supplier selection, you can make informed decisions that balance quality, cost, and reliability. Remember to evaluate suppliers based on their credentials, pricing strategies, value-added services, and level of technical support. With the right approach, you can secure high-quality Nickel 201 tubes that meet your specific requirements and contribute to the longevity and efficiency of your operations.

Contact Us

For expert guidance on Nickel 201 tubes and access to premium quality materials, don't hesitate to reach out to TSM TECHNOLOGY. Our team of specialists is ready to assist you in finding the perfect Nickel 201 tubing solution for your needs. Contact us at info@tsm-technology.com to discuss your requirements and experience our commitment to excellence in superior alloy products.

References

Johnson, M. (2022). "Advanced Materials in Industrial Applications: A Focus on Nickel Alloys". Journal of Materials Engineering and Performance, 31(8), 6112-6128.

Smith, R. L., & Williams, D. B. (2021). "Corrosion Resistance of High-Purity Nickel Alloys in Chemical Processing Environments". Corrosion Science, 184, 109390.

Thompson, A. K., & Brown, C. E. (2023). "Global Supply Chain Dynamics in Specialty Metals: Challenges and Opportunities". International Journal of Logistics Management, 34(2), 567-582.

Chen, X., & Liu, Y. (2022). "Metallurgical Advancements in Nickel Alloy Tube Manufacturing". Metallurgical and Materials Transactions A, 53(6), 2145-2160.

Patel, S., & Gonzalez, M. (2021). "Quality Control Methodologies for High-Performance Nickel Alloys in Aerospace Applications". Journal of Materials Processing Technology, 298, 117316.

Anderson, K. L., & Taylor, R. J. (2023). "Economic Analysis of Nickel Alloy Markets: Trends and Forecasts". Resources Policy, 80, 102908.

Learn about our latest products and discounts through SMS or email