- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

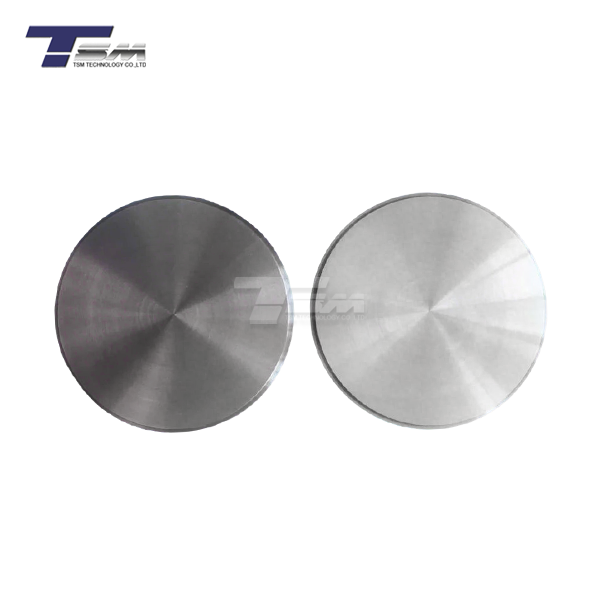

Hastelloy C276 Forgings

Size:φ(30~600)*Thk(600max)

Ship with MTC Acc.to EN 10204/3.1

Your Trusted Hastelloy C276 Forgings Manufacturer & Supplier

TSM Technology Co., Ltd is a leading supplier of Hastelloy C276 Forgings, specializing in high-quality nickel-based alloys for precision engineering industries. With over 14 years of expertise, we ensure superior corrosion-resistant materials tailored to meet demanding applications in aerospace, petrochemical, marine, and energy sectors. Our strict quality control system guarantees exceptional performance and reliability in every forging we deliver.

What is Hastelloy C276 Forgings?

Hastelloy C276 Forgings are high-performance nickel-molybdenum-chromium alloys with outstanding corrosion resistance in extreme environments. Known for their ability to withstand oxidizing and reducing conditions, these forgings are ideal for chemical processing, marine, and power industries.

Due to their superior resistance to pitting, stress corrosion cracking, and crevice corrosion, they are widely used in harsh applications where standard materials fail. Their excellent mechanical properties and weldability make them a preferred choice for critical industrial components.

Product Type

Supply type and form

Hastelloy C276 forgings are mainly customized, and the main types include:

Standard forgings: ring forgings, flanges, shafts, valve parts, etc., suitable for highly corrosive environments such as chemical equipment and marine engineering.

Special-shaped forgings: Customize complex geometric shapes (such as asymmetric structural parts, pipe joints, etc.) according to your drawings to meet special working conditions.

Supporting services: Provide welding materials, bolts and nuts and machined products (such as fine turning/polished parts) that match the forgings.

Specifications and processing capabilities

Size range: 50mm to 3000mm in diameter, adjustable thickness, support for super-large forging production.

Processing technology: Multi-directional die forging, isothermal forging technology, combined with solid solution annealing (1120-1170℃ rapid cooling) to ensure material uniformity and corrosion resistance.

Implementation standards and testing

Post-processing: surface polishing, pickling or sandblasting, providing non-destructive testing services such as ultrasonic flaw detection (UT) and penetrant testing (PT).

Standards: Following ASTM B564 (forgings), ASME SB-564.

Material Characteristics

Superior Corrosion Resistance: Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

High-Temperature Strength: Performs exceptionally well in extreme heat and pressure environments.

Excellent Weldability: This can be easily welded using standard methods without the need for post-weld heat treatment.

Versatile Applications: Suitable for highly aggressive chemical, marine, and power generation industries.

Hastelloy C-276(UNS N10276W.Nr.2.4819/NS336) |

||||||||||||||||

|

Chemical Composition |

Alloy |

% |

Ni |

Cr |

Fe |

Mo |

C |

Mn |

Si |

S |

P |

Co |

V |

W |

||

|

Hastelloy C |

min |

margin |

14.5 |

4 |

15 |

|

|

|

|

|

|

|

3 |

|||

|

|

max |

margin |

16.5 |

7 |

17 |

0.08 |

1 |

1 |

0.03 |

0.04 |

2.5 |

0.35 |

4.5 |

|||

|

C276 |

min |

margin |

14.5 |

4 |

15 |

|

|

|

|

|

|

|

3 |

|||

|

|

max |

margin |

16.5 |

7 |

17 |

0.01 |

1 |

0.08 |

0.03 |

0.04 |

2.5 |

0.35 |

4.5 |

|||

|

Physical Characteristics |

Density |

8.9g/cm³ |

||||||||||||||

|

Melting point |

1325-1370℃ |

|||||||||||||||

|

Minimum mechanical properties of alloys at room temperature |

Typical mechanical properties |

tensile strength Rm N/mm² |

Yield Strength RP0.2 N/mm² |

Elongation A5% |

Brinell hardness HB |

|||||||||||

|

Solution treatment |

690 |

283 |

40 |

|||||||||||||

Applications of Hastelloy C276 Forgings

Hastelloy C276 Forgings are widely used in industries requiring high corrosion resistance and strength, including:

Chemical Processing: Heat exchangers, reactors, evaporators, and piping systems.

Marine Industry: Seawater applications, shipbuilding, and offshore oil & gas platforms.

Aerospace & Power Generation: Turbine components, heat-resistant fasteners, and exhaust ducts.

Energy & Petrochemical: Gas processing, heat exchangers, and pressure vessels.

Factory and Equipment

Why Choose Us?

Global Availability

Reliable and timely delivery worldwide.

Customizable

Tailored sizes and processing per your requirements.

Competitive Pricing

Cost-effective solutions with bulk order discounts.

Customer Support

Dedicated team for technical assistance and after-sales service.

Packaging and shipment

FAQ

Q1: What are the key advantages of Hastelloy C276 Forgings?

A: Exceptional corrosion resistance, high strength, and superior weldability make it ideal for extreme environments.

Q2: Can you supply custom sizes?

A: Yes, we offer customized forging sizes and shapes to meet specific project requirements.

Q3: Do you provide material certifications?

A: Yes, all our products come with Mill Test Certificates (MTC) as per EN 10204/3.1.

Q4: What is the typical lead time for this product?

A: Standard sizes are available for quick shipment, while custom orders require 3-6 weeks, depending on specifications.

Contact Us

For inquiries about Hastelloy C276 Forgings, feel free to reach out to us:

Email: info@tsmnialloy.com

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email

_1739071678907.webp)