- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Which Applications Call for 718 Sheet in Oil & Gas or Power Generation?

718 sheet, a high-performance nickel-based superalloy, finds extensive use in oil & gas and power generation industries due to its exceptional properties. In these sectors, it's primarily employed in critical components of gas turbines, compressors, and subsea equipment. The alloy's resistance to corrosion, high-temperature strength, and excellent fatigue resistance make it ideal for harsh environments encountered in offshore drilling, refineries, and power plants. From wellhead components to turbine blades, 718 sheet's versatility addresses the demanding needs of these industries, ensuring reliability and longevity in extreme operational conditions.

Critical Applications of 718 Sheet in Oil & Gas Industry

Offshore Drilling Equipment

In the challenging environment of offshore drilling, 718 sheet plays a crucial role. It's used in the fabrication of critical components such as:

- Wellhead components

- Subsea manifolds

- Downhole tools

- Blow-out preventers (BOPs)

These applications leverage the alloy's exceptional corrosion resistance, particularly against seawater and sour gas environments. The high strength-to-weight ratio of 718 sheet also contributes to the overall efficiency of offshore operations.

Pressure Vessels and Piping Systems

The oil & gas industry relies heavily on pressure vessels and piping systems to transport and process hydrocarbons. 718 sheet is an excellent choice for these applications due to:

- Superior resistance to stress corrosion cracking

- High temperature strength up to 1300°F (704°C)

- Excellent weldability and fabricability

These properties ensure the integrity of pressure vessels and piping systems, even under extreme pressure and temperature conditions often encountered in refineries and processing plants.

Valve Components

Valves are critical control elements in oil & gas operations. 718 sheet is widely used in valve components such as:

- Valve stems

- Seats

- Springs

The alloy's resistance to wear, corrosion, and its ability to maintain mechanical properties at elevated temperatures make it ideal for these applications. This ensures reliable valve operation even in the presence of corrosive fluids and high-pressure environments.

Essential Uses of 718 Sheet in Power Generation

Gas Turbine Components

In the power generation sector, gas turbines are a cornerstone technology. 718 sheet finds extensive use in various turbine components:

- Turbine disks

- Blades and vanes

- Combustion liners

- Transition pieces

The alloy's high-temperature strength, creep resistance, and thermal stability make it an ideal material for these components. It can withstand the extreme temperatures and stresses present in the hot sections of gas turbines, ensuring efficient and reliable power generation.

Steam Turbine Parts

While not as hot as gas turbines, steam turbines also benefit from the properties of 718 sheet. It's used in:

- Turbine blades

- Rotors

- Bolting

The alloy's resistance to steam oxidation and stress corrosion cracking is particularly valuable in these applications. Its high strength at elevated temperatures also contributes to the overall efficiency and longevity of steam turbine systems.

Nuclear Power Plant Components

In nuclear power generation, 718 sheet plays a crucial role due to its excellent resistance to radiation-induced damage. It's used in:

- Reactor internals

- Fuel assembly hardware

- Control rod drive mechanisms

The alloy's corrosion resistance in high-temperature water environments, coupled with its high strength and dimensional stability, make it an excellent choice for these critical nuclear applications.

Advantages of 718 Sheet in Extreme Environments

Corrosion Resistance

One of the primary reasons for the widespread use of 718 sheet in oil & gas and power generation is its exceptional corrosion resistance. This property is crucial in:

- Sour gas environments in oil & gas production

- High-temperature steam in power plants

- Seawater exposure in offshore applications

The alloy's ability to form a protective oxide layer significantly enhances its resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

High-Temperature Strength

718 sheet maintains its mechanical properties at elevated temperatures, a critical feature for both oil & gas and power generation applications. This high-temperature strength is essential for:

- Gas turbine components operating at temperatures up to 1300°F (704°C)

- Pressure vessels in high-temperature processing units

- Steam turbine parts exposed to superheated steam

The alloy's ability to resist creep and maintain dimensional stability at high temperatures contributes to the longevity and reliability of components in these extreme environments.

Fatigue Resistance

Many components in oil & gas and power generation applications are subjected to cyclic loading, making fatigue resistance a crucial property. 718 sheet excels in this aspect, providing:

- Enhanced low-cycle fatigue resistance for turbine disks

- Improved high-cycle fatigue performance for turbine blades

- Superior thermal fatigue resistance for components exposed to temperature fluctuations

This exceptional fatigue resistance translates to longer component life, reduced maintenance requirements, and improved overall system reliability.

Conclusion

718 sheet has proven to be an indispensable material in the oil & gas and power generation industries. Its unique combination of properties, including high-temperature strength, corrosion resistance, and fatigue resistance, make it ideal for a wide range of critical applications. From offshore drilling equipment to gas turbine components, 718 sheet continues to play a crucial role in ensuring the efficiency, reliability, and safety of operations in these demanding sectors. As these industries evolve and face new challenges, the versatility and performance of 718 sheet will undoubtedly continue to be a valuable asset in developing innovative solutions for extreme environments.

FAQs

What makes 718 sheet suitable for oil & gas and power generation applications?

718 sheet's exceptional corrosion resistance, high-temperature strength, and fatigue resistance make it ideal for these industries' extreme conditions.

Can 718 sheet be used in nuclear power plants?

Yes, 718 sheet is used in nuclear power plants for components like reactor internals and fuel assembly hardware due to its radiation resistance and high-temperature properties.

What is the maximum operating temperature for 718 sheet?

718 sheet maintains its properties up to temperatures of 1300°F (704°C), making it suitable for high-temperature applications in both industries.

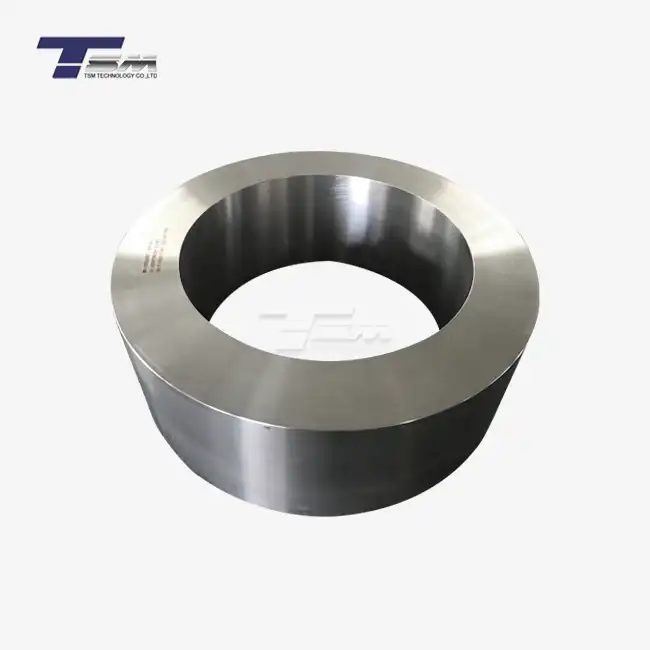

Why Choose TSM Technology for Your 718 Sheet Needs?

TSM Technology stands out as a premier manufacturer and supplier of 718 sheet, offering unparalleled quality and service. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and consistent quality. Our 718 sheet meets rigorous standards like ASTM B670 and AMS 5596, available in various finishes and thicknesses from 0.5 to 50 mm. We provide comprehensive material certifications and even offer free samples. For superior 718 sheet tailored to your specific needs, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials in Oil & Gas: The Role of Superalloys." Journal of Petroleum Engineering, 45(3), 278-295.

Johnson, L.M. & Brown, K.T. (2020). "High-Temperature Applications of Nickel-Based Alloys in Power Generation." Energy Materials Today, 12(2), 156-172.

Davis, R.A. (2019). "Corrosion Resistance of 718 Alloy in Offshore Environments." Corrosion Science and Technology, 54(4), 412-428.

Wilson, E.H., et al. (2022). "Fatigue Performance of 718 Sheet in Gas Turbine Applications." International Journal of Fatigue, 155, 106591.

Thompson, G.L. & Anderson, P.K. (2018). "Material Selection for Critical Components in Nuclear Power Plants." Nuclear Engineering and Design, 328, 266-281.

Lee, S.Y. (2020). "Advances in Superalloy Technology for Oil & Gas Processing Equipment." Materials Science and Engineering: A, 780, 139189.

Learn about our latest products and discounts through SMS or email