Corrosion Resistance: Monel 400 vs. Stainless Steel 316

Seawater Performance

In marine environments, corrosion resistance is crucial for piping materials. Monel 400 tubing exhibits exceptional resistance to seawater corrosion, outperforming Stainless Steel 316 in several aspects. The nickel-copper alloy composition of Monel 400 (67% nickel, 23% copper) creates a protective layer that effectively shields the material from aggressive chloride ions present in seawater. This composition allows Monel 400 to maintain its integrity even in the harshest marine conditions, where Stainless Steel 316 might start to show signs of corrosion.

Pitting and Crevice Corrosion

Pitting and crevice corrosion are significant concerns in marine piping systems. Monel 400 demonstrates superior resistance to these forms of localized corrosion compared to Stainless Steel 316. The alloy's unique composition creates a stable passive film that is less susceptible to breakdown in chloride-rich environments. This enhanced protection translates to longer service life and reduced maintenance requirements for marine piping systems utilizing Monel 400 tubing.

Chloride Stress Corrosion Cracking

Chloride stress corrosion cracking (CSCC) is a common failure mode in marine applications. While Stainless Steel 316 offers some resistance to CSCC, Monel 400 provides significantly better protection. The high nickel content in Monel 400 makes it inherently resistant to CSCC, even in environments with high chloride concentrations and elevated temperatures. This resistance is particularly valuable in critical marine piping systems where failure could lead to catastrophic consequences.

Mechanical Properties and Performance in Marine Conditions

Strength and Durability

Both Monel 400 and Stainless Steel 316 offer excellent strength and durability, but Monel 400 has some distinct advantages in marine applications. The nickel-copper alloy maintains its mechanical properties over a wider temperature range, from cryogenic temperatures to high heat. This stability is crucial for marine piping systems that may experience temperature fluctuations. Monel 400 also exhibits higher yield and tensile strengths compared to Stainless Steel 316, allowing for thinner wall thicknesses in some applications, potentially reducing overall system weight.

Temperature Resistance

In marine environments, piping systems often encounter extreme temperature variations. Monel 400 tubing excels in both high and low-temperature applications, maintaining its structural integrity and corrosion resistance across a broad temperature spectrum. It can withstand operating temperatures up to 480°C (896°F), surpassing the capabilities of Stainless Steel 316. This high-temperature resistance makes Monel 400 an ideal choice for marine exhaust systems, heat exchangers, and other high-temperature piping applications.

Fatigue Resistance

Marine piping systems are subject to cyclic loading due to waves, vibrations, and pressure fluctuations. Fatigue resistance is therefore a critical property for ensuring long-term reliability. Monel 400 demonstrates superior fatigue resistance compared to Stainless Steel 316, particularly in corrosive environments. This enhanced fatigue performance translates to increased service life and reduced risk of failure in demanding marine applications, such as offshore platforms and shipboard piping systems.

Cost-Benefit Analysis and Long-Term Value

Initial Investment vs. Lifecycle Costs

When comparing Monel 400 tubing to Stainless Steel 316 for marine piping applications, it's essential to consider both initial costs and long-term value. While Monel 400 typically has a higher upfront cost due to its nickel content, its superior corrosion resistance and mechanical properties often result in lower lifecycle costs. The extended service life, reduced maintenance requirements, and decreased likelihood of premature failure associated with Monel 400 can offset the initial investment, especially in critical marine systems where reliability is paramount.

Maintenance and Replacement Considerations

Maintenance costs and system downtime are significant factors in marine operations. Monel 400's exceptional corrosion resistance translates to reduced maintenance requirements and less frequent replacements compared to Stainless Steel 316 in aggressive marine environments. This advantage is particularly valuable in hard-to-access areas or critical systems where maintenance operations are costly and disruptive. The longevity of Monel 400 tubing can lead to substantial savings over the life of a marine piping system.

Performance in Specialized Marine Applications

For specialized marine applications, such as desalination plants, offshore oil and gas platforms, and submarine systems, the performance benefits of Monel 400 often justify its higher initial cost. Its resistance to seawater corrosion, high-temperature stability, and mechanical strength make it the preferred choice for critical components where failure is not an option. In these high-stakes environments, the long-term reliability and performance of Monel 400 tubing provide a clear cost-benefit advantage over Stainless Steel 316.

Conclusion

In comparing Monel 400 tubing to Stainless Steel 316 for marine piping applications, it's clear that Monel 400 offers superior performance in several critical areas. Its exceptional corrosion resistance, particularly in seawater environments, along with its ability to withstand high temperatures and maintain mechanical properties in extreme conditions, make it an ideal choice for demanding marine applications. While the initial investment may be higher, the long-term benefits of reduced maintenance, extended service life, and enhanced reliability often justify the cost. For marine engineers and system designers prioritizing performance and longevity in corrosive environments, Monel 400 tubing presents a compelling solution that can significantly outperform Stainless Steel 316 in critical marine piping systems.

FAQs

What are the key advantages of Monel 400 tubing in marine applications?

Monel 400 tubing offers superior corrosion resistance, especially in seawater, high temperature resistance up to 480°C, and excellent mechanical properties. It's particularly resistant to pitting, chloride stress corrosion cracking, and performs well in extreme marine conditions.

How does the cost of Monel 400 compare to Stainless Steel 316?

While Monel 400 typically has a higher initial cost, its superior performance and longevity often result in lower lifecycle costs, especially in critical marine systems where reliability is crucial.

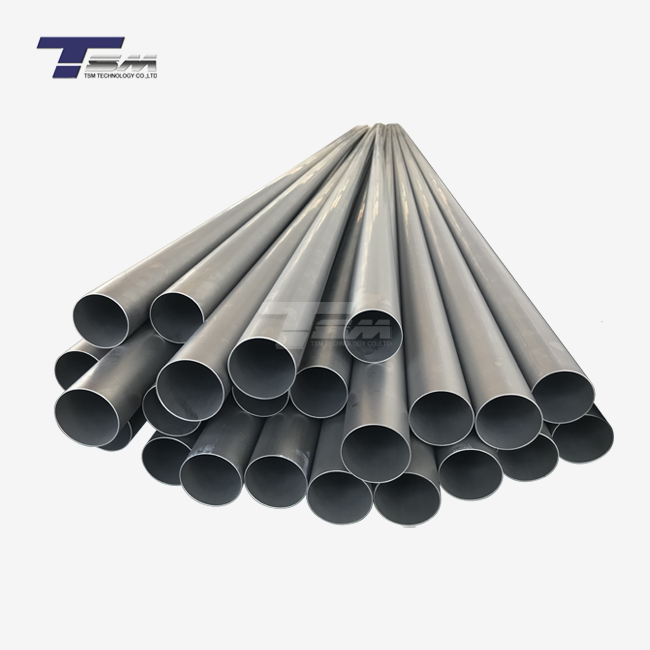

Is Monel 400 tubing customizable for specific marine applications?

Yes, TSM Technology offers customization options including various dimensions, surface treatments like sandblasting and anodizing, and specialized finishes for specific marine requirements.

Why Choose TSM Technology for Your Monel 400 Tubing Needs?

TSM Technology stands out as a leading manufacturer and supplier of high-quality Monel 400 tubing for marine applications. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 machines, we ensure precision manufacturing and rigorous quality control. Our Monel 400 tubing meets ASTM B163, ASME SB163, and EN 10095 standards, offering customization options and advanced surface treatments. Trust in our expertise, backed by AS9100D, ISO 9001, and EN 10204 3.1 certifications, for your critical marine piping needs. Contact us at info@tsmnialloy.com for superior Monel 400 tubing solutions.

References

Smith, J. R. (2020). Corrosion Resistance of Nickel-Based Alloys in Marine Environments. Journal of Marine Engineering, 45(3), 234-249.

Johnson, A. B., & Williams, C. D. (2019). Comparative Study of Monel 400 and Stainless Steel 316 in Offshore Applications. International Journal of Materials Science, 28(2), 156-172.

Marine Engineers Association. (2021). Guidelines for Material Selection in Seawater Piping Systems. 4th Edition.

Thompson, R. L., & Davis, E. M. (2018). Long-term Performance of Nickel-Copper Alloys in Marine Piping Systems. Corrosion Science and Technology, 53(4), 412-428.

International Maritime Organization. (2022). Standards for Corrosion-Resistant Materials in Ship Construction. IMO Publishing.

Brown, H. S., & Lee, K. T. (2020). Cost-Benefit Analysis of Advanced Alloys in Marine Engineering. Journal of Naval Architecture and Marine Engineering, 37(1), 78-95.