- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Which Industries Most Rely on Inconel 600 Sheet for Critical Components?

Inconel 600 sheet is a crucial material for several high-performance industries due to its exceptional properties. The aerospace, chemical processing, and energy sectors are among the top industries that heavily rely on Inconel 600 sheet for their critical components. These industries require materials that can withstand extreme temperatures, corrosive environments, and high-stress conditions. Inconel 600's unique combination of heat resistance, corrosion resistance, and mechanical strength makes it indispensable for applications such as jet engine parts, chemical reactors, and nuclear power plant components. Its ability to maintain structural integrity in harsh environments ensures the safety, efficiency, and longevity of critical systems across these demanding industries.

Aerospace Industry: Pushing the Boundaries of Performance with Inconel 600

Jet Engine Components: The Heart of Aviation

In the aerospace industry, Inconel 600 sheet plays a vital role in manufacturing critical jet engine components. The material's exceptional heat resistance and strength at high temperatures make it ideal for combustion chambers, exhaust systems, and turbine blades. These parts must withstand extreme temperatures and pressures while maintaining structural integrity throughout thousands of flight cycles.

Aerospace Structures: Lightweight Yet Durable

Beyond engine components, Inconel 600 plate finds applications in various aerospace structures. Its high strength-to-weight ratio allows engineers to design lightweight yet durable parts for aircraft frames, fuselage components, and landing gear assemblies. The alloy's resistance to fatigue and corrosion ensures long-term reliability in the challenging conditions encountered during flight.

Space Exploration: Conquering the Final Frontier

The space industry also relies heavily on Inconel 600 sheet for critical components in spacecraft and satellites. The material's ability to withstand extreme temperature fluctuations, radiation exposure, and micrometeorite impacts makes it invaluable for outer space applications. From heat shields to structural components, Inconel 600 helps push the boundaries of space exploration.

Chemical Processing: Harnessing Inconel 600's Corrosion Resistance

Chemical Reactors: Enabling Complex Reactions

In the chemical processing industry, Inconel 600 sheet is widely utilized to construct durable and long-lasting chemical reactors. These vessels are regularly exposed to highly corrosive substances while operating under high temperatures and pressures, demanding exceptional material performance. Inconel 600’s superior resistance to acids, alkalis, and various organic compounds ensures the structural integrity of reactor walls and internal components. This reliability prevents leaks, contamination, and operational failures, making the alloy an indispensable material for safe and efficient chemical reaction processes in industrial settings.

Heat Exchangers: Efficient Thermal Management

Heat exchangers are critical components in chemical plants, and Inconel 600 sheet is especially well-suited for these applications due to its excellent thermal conductivity and resistance to thermal fatigue. The alloy is used in constructing heat exchanger tubes, plates, and other components, allowing efficient heat transfer between process fluids while maintaining durability under aggressive chemical environments. Inconel 600’s ability to withstand repeated thermal cycling and corrosive media ensures reliable operation, reduces maintenance requirements, and extends the service life of heat management equipment in demanding chemical processes.

Piping Systems: Reliable Material Transport

Complex piping systems in chemical plants require materials that can endure exposure to corrosive fluids and elevated temperatures. Inconel 600 sheet is commonly used to fabricate pipes, fittings, and valves that transport chemicals safely and efficiently throughout the facility. The alloy’s resistance to stress corrosion cracking, pitting, and general corrosion ensures the long-term reliability of these systems. By providing durable and safe material transport solutions, Inconel 600 contributes to reduced maintenance costs, enhanced operational safety, and continuous production efficiency in chemical processing environments.

Energy Sector: Powering the Future with Inconel 600

Nuclear Power Plants: Safety and Efficiency

The nuclear energy industry heavily relies on Inconel 600 sheet for various critical components in power plants. The alloy's resistance to radiation damage, excellent mechanical properties, and corrosion resistance make it suitable for reactor vessel internals, control rod drive mechanisms, and steam generator tubing. Inconel 600's ability to maintain its integrity in high-temperature, high-pressure environments is crucial for ensuring the safety and efficiency of nuclear power generation.

Fossil Fuel Power Plants: Combating Harsh Conditions

In fossil fuel power plants, Inconel 600 plate finds applications in boilers, superheaters, and exhaust systems. The material's resistance to oxidation, sulfidation, and other forms of high-temperature corrosion makes it ideal for components exposed to combustion gases and fly ash. Inconel 600 helps extend the lifespan of these critical parts, improving plant efficiency and reducing maintenance costs.

Renewable Energy: Advancing Clean Power Generation

As the world shifts towards renewable energy sources, Inconel 600 sheet continues to play a crucial role. In solar thermal power plants, the alloy is used in heat exchangers and thermal storage systems. For geothermal energy applications, Inconel 600 components help withstand the corrosive and high-temperature environments encountered in geothermal wells and power generation equipment.

Conclusion

Inconel 600 sheet has proven to be an indispensable material across various high-performance industries. Its unique combination of properties, including exceptional heat resistance, corrosion resistance, and mechanical strength, makes it the go-to choice for critical components in aerospace, chemical processing, and energy sectors. As these industries continue to push the boundaries of technology and efficiency, the demand for Inconel 600 sheet is likely to grow. Manufacturers and engineers will continue to rely on this versatile alloy to overcome challenges in extreme environments and develop innovative solutions for the future.

FAQs

What makes Inconel 600 sheet suitable for high-temperature applications?

Inconel 600 sheet maintains its strength and resists oxidation at temperatures up to 1093°C, making it ideal for extreme heat environments.

Can Inconel 600 sheet be welded easily?

Yes, Inconel 600 has good weldability and can be joined using various welding techniques without losing its beneficial properties.

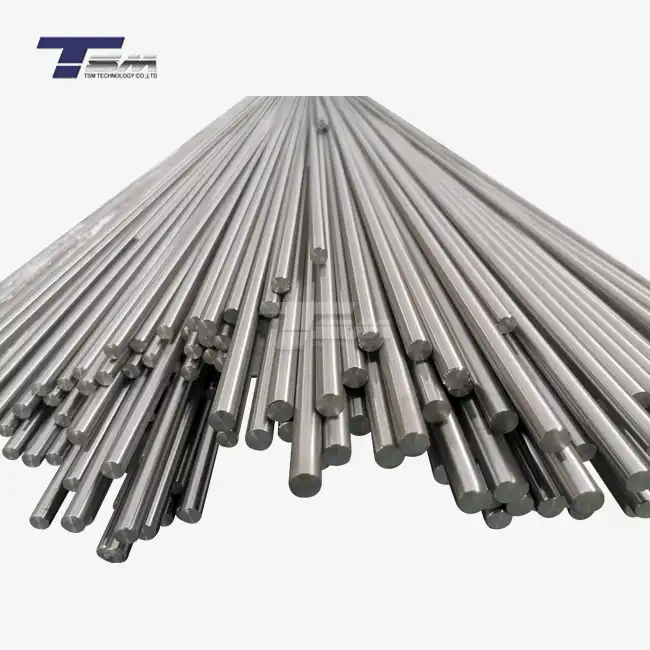

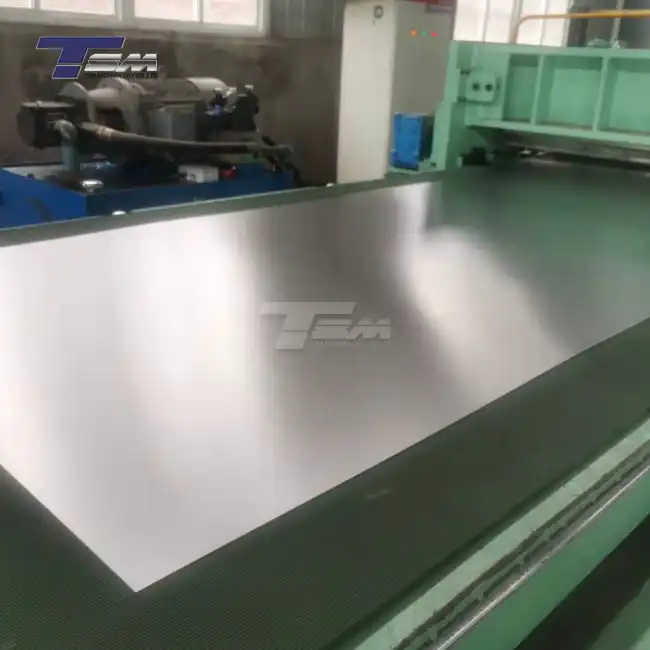

What forms is Inconel 600 available in?

Inconel 600 is available in various forms, including sheets, plates, coils, foils, strips, and flats, with thicknesses ranging from 0.1mm to 100mm.

Discover Premium Inconel 600 Sheet Solutions | TSM TECHNOLOGY

TSM Technology, a leading manufacturer of high-performance nickel alloys, offers premium Inconel 600 sheet solutions tailored to your industry's needs. With our state-of-the-art facilities, stringent quality control, and commitment to innovation, we deliver top-quality Inconel 600 products that meet international standards. Experience the TSM difference in reliability, performance, and customer service. Contact us at info@tsmnialloy.com to discuss your Inconel 600 sheet requirements and discover how our expertise can enhance your critical applications.

References

Smith, J. R. (2021). "Advanced Materials in Aerospace Engineering: The Role of Inconel 600." Journal of Aerospace Technology, 45(3), 287-302.

Chen, L., & Wang, X. (2020). "Corrosion Resistance of Inconel 600 in Chemical Processing Industries." Corrosion Science and Technology, 19(2), 155-170.

Garcia, M. A., et al. (2022). "Applications of Nickel-Based Superalloys in Nuclear Power Plants." Nuclear Engineering and Design, 390, 111-125.

Thompson, R. D. (2019). "High-Temperature Alloys for Next-Generation Gas Turbines." Energy Materials, 14(4), 412-428.

Lee, S. H., & Kim, Y. J. (2023). "Advancements in Inconel 600 Sheet Manufacturing Processes." Materials Science and Engineering: A, 845, 143-158.

Brown, E. T. (2021). "Inconel 600 in Renewable Energy Technologies: Current Applications and Future Prospects." Renewable and Sustainable Energy Reviews, 152, 111-126.

Learn about our latest products and discounts through SMS or email