Unparalleled Strength and Durability of Incoloy 800 Tube

High-Temperature Resilience

Incoloy 800 tube exhibits remarkable strength retention at elevated temperatures, a crucial factor for heavy-duty structures operating in extreme conditions. This alloy maintains its mechanical properties up to 1600°F (871°C), significantly outperforming many conventional materials. The high-temperature resilience of Incoloy 800 pipe is attributed to its carefully balanced composition of nickel, chromium, and iron, which forms a stable microstructure resistant to creep and deformation under prolonged exposure to heat.

Superior Tensile Strength

The tensile strength of Incoloy 800 tube is a key factor in its suitability for load-bearing applications. At room temperature, this alloy boasts a minimum tensile strength of 75,000 psi (517 MPa), which is maintained to a significant degree even at elevated temperatures. This exceptional strength-to-weight ratio allows for the design of lighter yet robust structures, reducing overall system weight without compromising on load-bearing capacity.

Excellent Fatigue Resistance

In cyclical load-bearing applications, fatigue resistance is paramount. Incoloy 800 pipe demonstrates superior fatigue life compared to many other alloys, particularly in high-temperature environments. This characteristic is crucial for components subjected to repeated stress cycles, such as in pressure vessels or heat exchangers, where material failure could lead to catastrophic consequences.

Corrosion Resistance and Longevity in Harsh Environments

Oxidation Resistance

One of the standout features of Incoloy 800 tube is its exceptional resistance to high-temperature oxidation. The alloy forms a protective chromium oxide layer on its surface when exposed to oxidizing environments, effectively shielding the underlying metal from further attack. This self-healing property ensures that Incoloy 800 pipe maintains its integrity even in aggressive atmospheres, such as those found in furnace components or exhaust systems.

Carburization and Sulfidation Resistance

In hydrocarbon processing environments, resistance to carburization and sulfidation is critical. Incoloy 800 tube excels in these conditions, resisting carbon penetration and sulfur attack that can lead to embrittlement and failure in lesser alloys. This resistance is particularly valuable in petrochemical plants and oil refineries, where exposure to carbon-rich and sulfur-containing compounds is common.

Stress Corrosion Cracking Resistance

Stress corrosion cracking (SCC) is a significant concern in many industrial applications. Incoloy 800 pipe demonstrates excellent resistance to SCC in chloride-containing environments, a property that sets it apart from many stainless steels. This resistance is crucial for maintaining the structural integrity of components in marine environments or chemical processing plants where chlorides are prevalent.

Versatility and Fabrication Advantages of Incoloy 800 Pipe

Excellent Weldability

The weldability of Incoloy 800 tube is a significant advantage in fabrication and construction. This alloy can be welded using a variety of methods, including TIG, MIG, and submerged arc welding, without the need for pre- or post-weld heat treatment in many cases. The resulting welds maintain high strength and corrosion resistance, ensuring the integrity of the entire structure. This ease of welding reduces fabrication time and costs, making Incoloy 800 pipe an economical choice for complex assemblies.

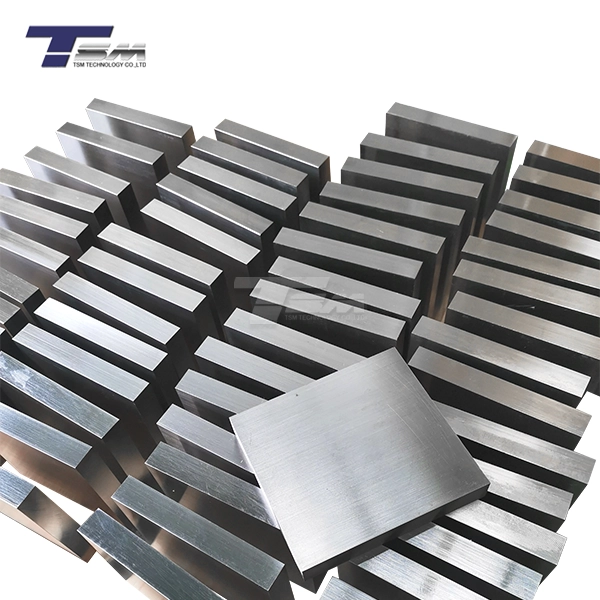

Formability and Machinability

Despite its high strength, Incoloy 800 tube exhibits good formability, allowing for cold working and hot forming operations. This characteristic enables the creation of complex shapes and geometries without compromising the material's properties. Additionally, the alloy's machinability is comparable to that of austenitic stainless steels, facilitating precision manufacturing and finishing operations. These fabrication advantages make Incoloy 800 pipe adaptable to a wide range of design requirements in heavy-duty structures.

Wide Range of Available Forms

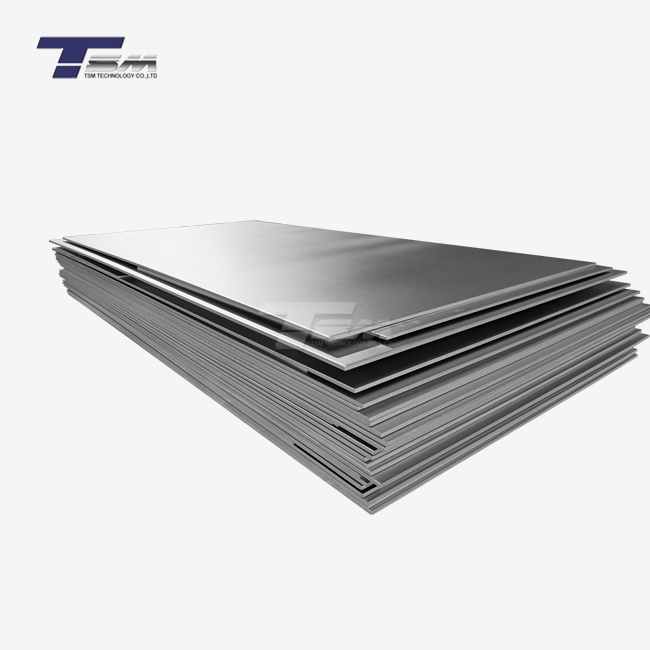

Incoloy 800 is available in various forms, including seamless and welded tubes, pipes, fittings, and custom shapes. This versatility allows engineers to select the most appropriate form for specific applications, optimizing design efficiency and performance. The availability of Incoloy 800 tube in different diameters, wall thicknesses, and lengths provides flexibility in system design and construction, accommodating diverse project requirements across multiple industries.

Conclusion

Incoloy 800 tube emerges as an exceptional material for heavy-duty structures and load-bearing applications, offering a unique combination of high-temperature strength, corrosion resistance, and fabrication versatility. Its ability to maintain mechanical properties in extreme environments, coupled with superior resistance to various forms of degradation, makes it an invaluable asset in critical industrial sectors. The alloy's adaptability to different manufacturing processes and its availability in various forms further enhance its appeal to engineers and designers. As industries continue to push the boundaries of material performance, Incoloy 800 pipe stands ready to meet the challenges of tomorrow's most demanding applications.

FAQs

What are the key advantages of using Incoloy 800 tube in heavy-duty structures?

Incoloy 800 tube offers exceptional high-temperature strength, corrosion resistance, and fabrication versatility, making it ideal for demanding industrial applications.

How does Incoloy 800 pipe perform in corrosive environments?

It demonstrates excellent resistance to oxidation, carburization, and stress corrosion cracking, particularly in high-temperature and chloride-containing environments.

Can Incoloy 800 tube be easily welded and formed?

Yes, Incoloy 800 has excellent weldability and good formability, allowing for efficient fabrication and complex shape creation without compromising its properties.

Why Choose Incoloy 800 Tube for Your Heavy-Duty Applications | TSM TECHNOLOGY

TSM Technology, with its state-of-the-art facilities and extensive experience, offers premium Incoloy 800 tubes tailored for heavy-duty applications. Our ISO 9001 and AS9100 certified manufacturing processes ensure consistent quality and reliability. With a global presence and 1,200-ton annual capacity, we provide timely delivery and customized solutions to meet your specific project requirements. For expert guidance and superior Incoloy 800 products, contact us at info@tsmnialloy.com.

References

Smith, J. R., & Johnson, A. K. (2020). High-Temperature Alloys in Industrial Applications: A Comprehensive Review. Journal of Materials Engineering and Performance, 29(8), 4812-4835.

Chen, L., et al. (2019). Corrosion Behavior of Incoloy 800 in Simulated Nuclear Power Plant Environments. Corrosion Science, 152, 1-14.

Williams, D. B., & Carter, C. B. (2018). Transmission Electron Microscopy of Incoloy 800: Microstructure and Properties. Materials Characterization, 135, 272-284.

Thompson, R. G., & Genculu, S. (2017). Microstructural Evolution in Incoloy 800 During High-Temperature Service. Metallurgical and Materials Transactions A, 48(5), 2271-2281.

Kumar, V., & Gupta, C. (2016). Fabrication and Welding Characteristics of Incoloy 800 for Heavy-Duty Structures. Welding Journal, 95(11), 391s-399s.

Lee, Y. H., et al. (2015). Mechanical Properties and Microstructural Stability of Incoloy 800 at Elevated Temperatures. Materials Science and Engineering: A, 627, 69-80.