- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

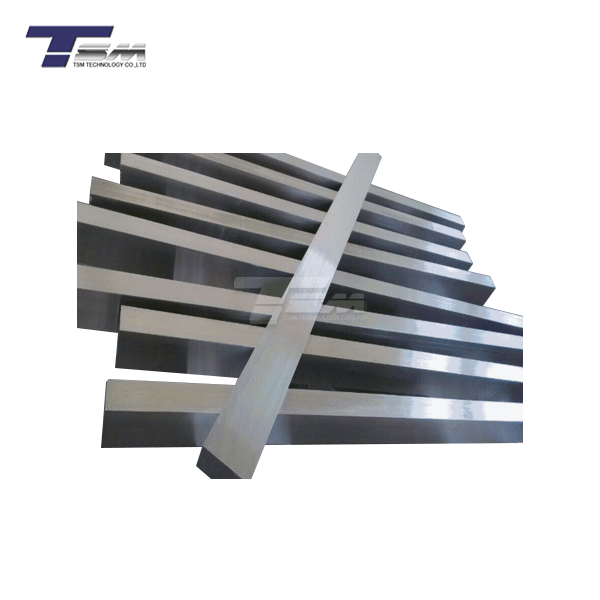

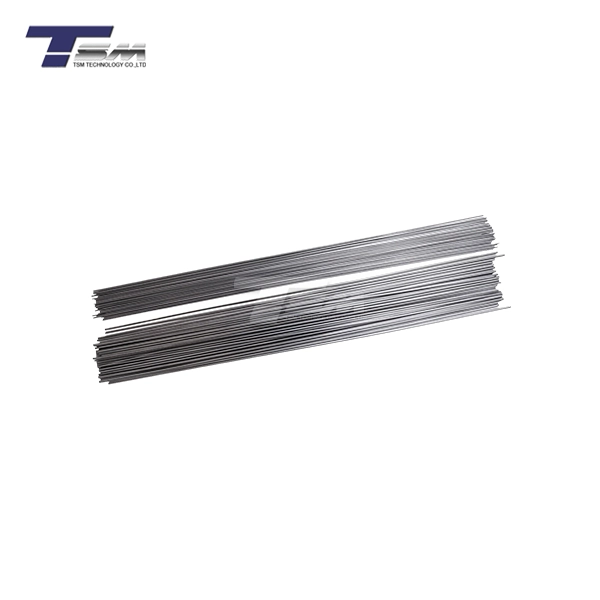

Nickel Alloy Wire

3 factories × 8 production lines × 100+ machines

Material Options:MONEL 400, INCONEL 600, HASTELLOY C276

Diameter Range: 0.05 mm – 12.0 mm

Form: Coiled, Straight, or Precision-cut

Standards: ASTM, ISO, DIN, JIS

Processing: Cold-drawn, annealed, or hardened

Certifications: Mill Test Reports (MTR), ISO 9001

Custom Services: Alloy composition adjustment, special coatings

Nickel Alloy Wire: Superior Performance for Demanding Applications

Since 2011, TSM Technology has grown into a world-class manufacturer of premium Nickel Alloy Wire, leveraging our 3,200㎡ modern production base in Shaanxi, China. Equipped with vacuum arc furnaces and 2,500-ton forging presses, we maintain complete vertical integration with 1,200-ton annual capacity. Our advanced processing technology and rigorous quality control deliver superior nickel alloy products - including wires, plates, tubes, and forgings - that meet the stringent demands of aerospace, medical, energy, and chemical industries. With 14 years of expertise, we combine innovation with reliability to provide high-performance metal solutions globally.

What are Nickel Alloy Wires?

The items are flexible materials known for their extraordinary erosion resistance, high-temperature quality, and solidity. These wires are composed of nickel and other components, making combinations with one-of-a-kind properties appropriate for challenging situations.

Specification

| Property | Value |

|---|---|

| Diameter Range | 0.05 mm - 12.0 mm |

| Form | Coiled, Straight, or Precision-cut |

| Processing | Cold-drawn, annealed or hardened |

Physical and Chemical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550-1240 MPa |

| Elongation | 30-60% |

| Melting Point | 1300-1450°C |

| Density | 8.4-8.9 g/cm³ |

Product Standards

Our products comply with international standards including ASTM, ISO, DIN, and JIS, ensuring consistent quality and performance.

Features of Nickel Alloy Wire

- Excellent corrosion resistance

- High-temperature strength

- Superior mechanical properties

- Good weldability

- Resistance to oxidation and sulfidation

Production and Processing Technology

TSM Technology employs advanced manufacturing techniques for nickel alloy wire production, including precision melting, controlled hot and cold working, and targeted heat treatment. From raw material selection to cold drawing and surface finishing, each step ensures optimal properties and dimensional accuracy. Rigorous quality control covers material composition, mechanical properties, surface inspection, and non-destructive testing, guaranteeing reliable performance for critical applications.

Applications

Nickel Alloy Wire finds extensive use in:

- Aerospace components

- Medical devices

- Chemical processing equipment

- Oil and gas industry

- Electronics manufacturing

Package and Shipping

Our item is carefully bundled to guarantee assurance amid transportation. We offer different shipping choices to meet your conveyance needs.

Why Choose TSM Technology?

Global Supply Chain

Reliable worldwide distribution network

Strategic raw material reserves

Customized Solutions

Tailored alloy compositions for specific applications

Rapid response to special requirements

Traceability Management

Complete material history documentation

Heat number tracking system

Comprehensive Quality Assurance

ISO 9001/13485, AS9100D, and NADCAP certifications

Full compliance with industry standards

Precision Manufacturing

Tight tolerance control

Customized surface treatments for medical and chemical applications

Advanced Material Technology

High-purity nickel alloy production

Precise composition control for optimal properties

Company Exhibition

TSM Technology regularly participates in international trade shows and industry exhibitions, showcasing our latest innovations in the product technology.

FAQ

Q: What is the minimum order quantity for the product?

A: Our MOQ varies depending on the specific alloy and dimensions. Please contact us for details.

Q: Can you provide custom product compositions?

A: Yes, we offer custom alloy formulations to meet specific application requirements.

Q: What certifications do your products have?

A: Our products are certified to ISO 9001, AS9100D, and NADCAP standards.

Q: How long is the typical lead time for the product orders?

A: Lead times vary based on quantity and specifications. Standard orders are usually processed within 2-4 weeks.

Q: Do you offer samples of your product?

A: Yes, we give tests for testing and assessment. Contact our deals group for more data.

Contact Us

For more information about our Nickel Alloy Wire products or to discuss your specific needs, please contact us at info@tsmnialloy.com. Our group of specialists is prepared to help you in finding the culminate arrangement for your application.

Learn about our latest products and discounts through SMS or email

Learn about our latest products and discounts through SMS or email