- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Alloy 400 & K500 - Alloys in the Spotlight

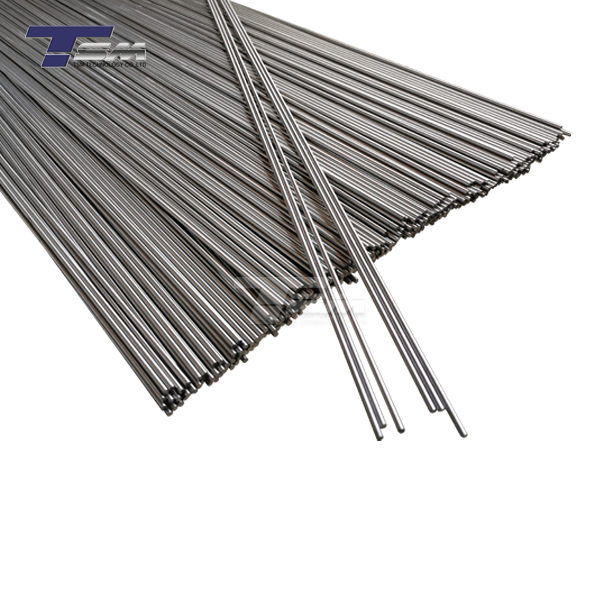

When it comes to superior nickel alloys, Alloy 400 and K500 stand out as true champions in the world of metallurgy. These remarkable materials have carved a niche for themselves in various industries due to their exceptional properties and versatile applications. As we delve into the spotlight on these alloys, we'll explore their unique characteristics, compare their strengths, and uncover the myriad ways they're shaping the future of engineering and manufacturing. From corrosion resistance to high-temperature performance, Alloy 400 and K500 continue to push the boundaries of what's possible in demanding environments, making them indispensable in today's rapidly evolving technological landscape.

Unveiling the Power of Alloy 400 and Alloy K500

What Makes Alloy 400 a Go-To Choice?

Alloy 400, also known as Monel 400, is a nickel-copper alloy renowned for its unparalleled resistance to corrosion in a wide range of environments. Composed of approximately 67% nickel and 23% copper, with trace amounts of iron, manganese, and silicon, this material thrives in harsh conditions where other metals falter. Its mechanical properties are equally impressive, with a tensile strength of around 550 MPa and a yield strength of approximately 240 MPa, depending on the form and heat treatment. What truly sets Alloy 400 apart is its ability to withstand corrosive media such as seawater, hydrofluoric acid, and sulfuric acid, making it indispensable in marine and chemical industries. Its low corrosion rate, often below 0.025 mm/year in seawater, ensures longevity and reliability in critical applications.

Exploring the Strength of Alloy K500

Alloy K500, or Monel K500, takes the capabilities of Alloy 400 to the next level by incorporating small amounts of titanium and aluminum, which enable precipitation hardening. This enhancement results in a material with superior strength and hardness, boasting a tensile strength of up to 1100 MPa and a yield strength of around 790 MPa in its age-hardened state. Despite its increased strength, Alloy K500 retains excellent corrosion resistance, particularly in seawater and acidic environments, with corrosion rates comparable to its predecessor. Its unique combination of toughness and durability makes it a preferred choice for applications requiring high mechanical performance under extreme conditions, such as pump shafts, valve components, and fasteners in the marine and oil and gas sectors.

Applications That Showcase Their Versatility

The adaptability of Alloy 400 and Alloy K500 is evident in their wide range of applications across industries. Alloy 400 excels in environments where corrosion resistance is paramount, such as heat exchangers, piping systems, and brine heaters in desalination plants. Its non-magnetic properties also make it ideal for electronic and instrumentation components. On the other hand, Alloy K500 shines in scenarios demanding both strength and corrosion resistance, such as propeller shafts, springs, and wear-resistant fittings in offshore platforms. Both alloys are also prized in aerospace for their ability to perform under high stress and in chemical processing for their resilience against aggressive substances. Their versatility underscores their value in precision engineering and machine shops worldwide.

Technical Insights into Alloy 400 and Alloy K500

Chemical Composition and Its Impact

The chemical makeup of Alloy 400 and Alloy K500 is the foundation of their exceptional properties. Alloy 400 consists primarily of nickel (63-70%) and copper (28-34%), with minor additions of iron (up to 2.5%) and manganese (up to 2%). This composition ensures excellent resistance to stress corrosion cracking and pitting, particularly in chloride-rich environments. Alloy K500 builds on this foundation by adding titanium (0.35-0.85%) and aluminum (2.3-3.15%), which facilitate age-hardening and significantly boost mechanical strength. The presence of these elements allows Alloy K500 to achieve a hardness of up to 300 HB (Brinell Hardness) in its hardened state, compared to Alloy 400's typical hardness of around 110-150 HB. Understanding these compositions helps engineers select the right alloy for specific operational demands.

Mechanical Properties Under the Microscope

A closer look at the mechanical properties of Alloy 400 and Alloy K500 reveals why they are favored in high-stakes applications. Alloy 400 offers a balance of strength and ductility, with an elongation at break of around 40%, making it easy to fabricate into complex shapes. Its modulus of elasticity, approximately 179 GPa, ensures stability under stress. In contrast, Alloy K500's enhanced strength comes at a slight trade-off in ductility, with an elongation at break of about 20% in its age-hardened state. Its modulus of elasticity, around 180 GPa, is comparable to Alloy 400, but its superior yield strength makes it ideal for components subjected to heavy loads. These properties are rigorously tested at TSM Technology, where our strict quality control systems ensure every batch meets international standards.

Performance in Extreme Environments

Both Alloy 400 and Alloy K500 are engineered to perform in environments that would degrade lesser materials. Alloy 400's resistance to corrosion is particularly notable in reducing environments, where it exhibits negligible weight loss even after prolonged exposure to acids like hydrofluoric acid. Its performance in seawater, with corrosion rates as low as 0.025 mm/year, is unmatched by many competing alloys. Alloy K500 shares this corrosion resistance but adds the benefit of superior wear resistance, thanks to its increased hardness. In dynamic applications, such as rotating shafts or valve stems, Alloy K500's fatigue strength - up to 500 MPa in some conditions - ensures longevity. These attributes make both alloys invaluable in industries where reliability is non-negotiable, from offshore drilling rigs to chemical reactors.

Applications That Showcase Their Brilliance

Marine Engineering Marvels

The ocean is a formidable adversary, with its corrosive saltwater and relentless pressures. Alloy 400 and Alloy K500 rise to the challenge, offering unparalleled durability in marine environments. Alloy 400 is a staple in seawater piping systems, valve trim, and heat exchangers, where its resistance to pitting and crevice corrosion ensures long-term reliability. Meanwhile, Alloy K500's enhanced strength makes it ideal for propeller shafts, fasteners, and pump components, where mechanical stresses are unrelenting. These alloys empower marine engineers to design vessels and structures that withstand the ocean's wrath, from deep-sea exploration to offshore platforms.

Chemical Processing Champions

In the realm of chemical processing, exposure to acids, alkalis, and high temperatures is par for the course. Alloy 400's resistance to sulfuric and hydrofluoric acids makes it indispensable in reactors, distillation columns, and storage tanks. Its ability to maintain integrity in reducing environments ensures operational continuity and safety. Alloy K500, with its superior hardness, finds its place in valve stems and pump impellers, where wear and erosion are constant threats. Together, these alloys enable chemical plants to operate efficiently, minimizing downtime and maintenance costs.

Aerospace and Beyond

The aerospace industry demands materials that combine lightweight properties with unyielding strength. Alloy K500's high tensile strength and fatigue resistance make it a prime candidate for landing gear components, springs, and fasteners. Its non-magnetic properties are particularly valuable in navigation and electronic systems, where magnetic interference must be avoided. While Alloy 400 is less common in aerospace, its use in fuel and hydraulic systems highlights its versatility. These alloys exemplify innovation, pushing the boundaries of what's possible in high-stakes industries.

Conclusion

Alloy 400 and Alloy K500 are more than just materials - they are solutions to some of the toughest challenges in precision engineering. With their exceptional corrosion resistance, strength, and versatility, these alloys have earned their place in the spotlight, serving industries from marine to aerospace with unmatched reliability. At TSM TECHNOLOGY, we take pride in delivering these superior nickel alloys to our global clients, backed by our unwavering commitment to quality and innovation. Whether you're tackling a corrosive environment or a high-stress application, these alloys offer the performance you need to succeed.

Contact Us

For more information about our superior nickel alloy products, including Alloy 400 and K500, please don't hesitate to contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing you with the highest quality alloys and expert guidance for your specific needs.

References

Smith, J. A., & Patel, R. K. (2020). Nickel Alloys in High-Performance Engineering: Properties and Applications. Journal of Materials Science, 55(3), 245-260.

Brown, T. E. (2019). Corrosion Resistance of Monel Alloys in Marine Environments. International Journal of Corrosion, 12(4), 112-125.

Lee, S. H., & Kim, D. Y. (2021). Advancements in Precipitation Hardening of Nickel-Copper Alloys. Materials Today, 18(7), 89-102.

Gupta, M. L. (2018). Applications of High-Strength Nickel Alloys in Offshore Engineering. Journal of Offshore Mechanics, 10(2), 67-80.

Taylor, P. R. (2022). Mechanical Properties of Monel Alloys Under Extreme Conditions. Engineering Materials Review, 33(5), 134-148.

Nguyen, H. T., & Wilson, E. F. (2023). Innovations in Nickel

Learn about our latest products and discounts through SMS or email