Metal 600 is a high-performance nickel-chromium-iron metal that is used in many industries because it is very good at resisting heat and corrosion. This all-inclusive guide goes into great detail about the chemicals that make up Alloy 600 and discusses why engineers like using it. We'll look at the exact mix of elements that make it work so well, talk about how it can be used in a lot of different fields, and share information on how this alloy's composition affects how it acts when conditions change. If you want to know what kind of material has great mechanical properties or you're creating equipment that will work in tough conditions, you need to know about Alloy 600's chemicals to make smart choices in engineering.

Understanding the Chemical Composition of Alloy 600

Primary Elements in Alloy 600

The carefully matched chemicals that make up Alloy 600 give it amazing qualities. The main parts are:

- Nickel (Ni): at least 72%

- Chromium (Cr): 14% to 17%

- Fe: 6–10%

This superalloy is resistant to chloride stress corrosion cracks and stays stable in hot places because it has a lot of nickel in it. Iron makes the metal stronger and easier to work with, and chromium makes a protective oxide layer that makes it more resistant to corrosion.

Secondary Elements and Their Roles

Alloy 600 has several secondary elements that fine-tune its qualities in addition to its main parts:

- C: at most 0.15%

- Manganese (Mn): no more than 1.0%

- Silicon (Si): no more than 0.5%

- Sulfur (S): no more than 0.015%

- Cu (Copper): at most 0.5%

These things are very important for making the metal work better. For example, carbon makes metals stronger and harder, and manganese makes them more resistant to wear and corrosion. Silicon helps make oxides, which makes the resistance to rust even better.

Trace Elements and Impurities

It is very important to keep control of the minor elements and impurities in Alloy 600:

- Phosphorus (P): no more than 0.025%

- Aluminum (Al) + Titanium (Ti): no more than 0.5% together

Tight control of these factors makes sure that the metal always works the same way in different situations. Phosphorus and other impurities can make the material weaker. Keeping these impurities low helps keep the material strong.

Properties and Characteristics Derived from Alloy 600's Composition

Corrosion Resistance

The chemicals that make up Alloy 600 give it great protection against corrosion in a lot of different settings. When chromium is added to the mix, the high nickel content creates a steady passive film that keeps the alloy from oxidizing and rusting. This means it's especially good for apps that involve

- Acids, Bases, and pH

- Steam at a high temperature

- Places that have a lot of chloride

Better than many stainless steels, the alloy can fight stress corrosion cracking in environments that have chloride in them. This makes it a great choice for important parts in chemical processing and nuclear power generation.

Mechanical Properties

Alloy 600 has great mechanical qualities because it is made up of a balanced mix of materials:

- Tensile Strength: 550–690 MPa (80–100 ksi)

- Yield Strength: 25–50 ksi (170–345 MPa)

- Elongation: 30 to 40%

Alloy 600 has these qualities that make it useful for cases that need high strength and ductility. Because it has a lot of nickel in it, the alloy keeps its mechanical stability over a wide range of temperatures, from very cold to very hot.

Thermal Characteristics

The thermal qualities of Alloy 600 are also affected by what it is made of:

- The temperature at which this substance starts to melt and completely melts is between 1,354°C (2,470°F) and 1,413°C (2,575°F)

- Thermal Conductivity: 14.9 W/m·K at 20° Celsius

- Thermal Expansion Coefficient: 13.3 µm/m·°C (20–100°C)

Alloy 600 is a great option for use in high-temperature settings because it can fight oxidation and stay stable when it gets hot. The carefully balanced chemical makeup of the alloy is what lets it keep its qualities even when temperatures rise.

Applications and Industries Benefiting from Alloy 600

Nuclear Power Generation

Alloy 600's chemical makeup makes it especially good for use in nuclear power.

- Steam generator tubing

- Pressurizer heater covers

- Ways to control rod drive

It's a very important material for nuclear power plant parts because it doesn't break down in high temperatures or in pressurized water reactor (PWR) setting. But it has been replaced by Alloy 690 in some uses because it works better in certain conditions.

Chemical Processing Industry

Alloy 600 is used in many different ways in the chemical business because it doesn't corrode easily:

- Heat transfer devices

- Containers for chemical reactions

- Systems of pipes

It is very useful in processes that use acids, caustics, and chlorides because it can resist harsh chemicals and hot temperatures. The makeup of the metal lets it keep its shape in places where other materials would break down quickly.

Aerospace and Gas Turbine Industries

Alloy 600 is used in aircraft and gas turbine engines because it can handle high temperatures and doesn't rust easily:

- Fire tanks

- Systems for exhaust

- Parts of the afterburner

Because of how it is chemically made as an alloy, it can keep its properties even when the temperature is very high. This makes it a good material for parts that go through a lot of heat and stress in airplanes and power generation turbines.

Conclusion

The chemicals that make up Alloy 600 give it an amazing ability in tough conditions. By carefully balancing nickel, chromium, and iron and precisely controlling secondary and trace elements, this alloy gives a one-of-a-kind mix of thermal stability, corrosion protection, and mechanical strength. Engineers who work in high-performance fields like nuclear power, chemical processing, aircraft, and others need to know about Alloy 600's composition so they can choose the right materials. Because chemical makeup has a big effect on a material's characteristics and uses, as, for example, in the case of Alloy 600, which remains a standard for high-performance nickel-based alloys even as material science changes.

FAQs

Why doesn't Alloy 600 corrode?

Alloy 600 can prevent corrosion because it has a lot of nickel and chromium, which protect the surface by forming an oxide layer.

What is it about Alloy 600's chemicals that affects how it works at high temperatures?

Alloy 600 can keep its mechanical qualities and avoid oxidation at high temperatures because it is rich in nickel and has balanced alloying elements.

What are the downsides of using Alloy 600 in nuclear applications?

Alloy 600 has been used a lot in nuclear power plants, but it can corrode in some conditions, which has led to the creation of better alloys like Alloy 690 for certain uses.

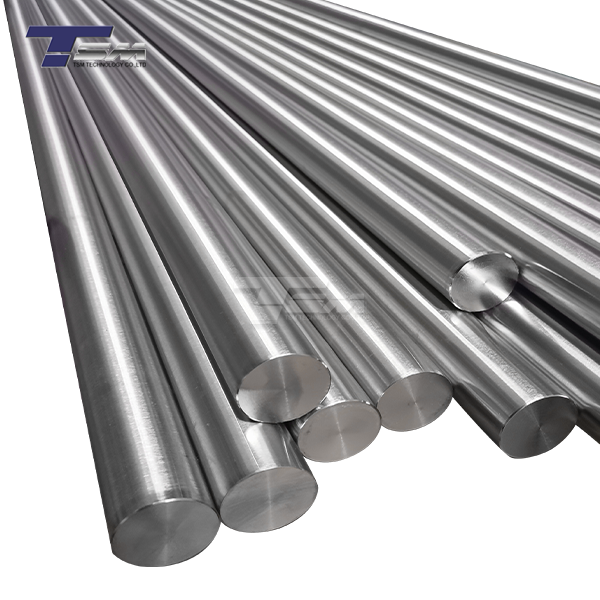

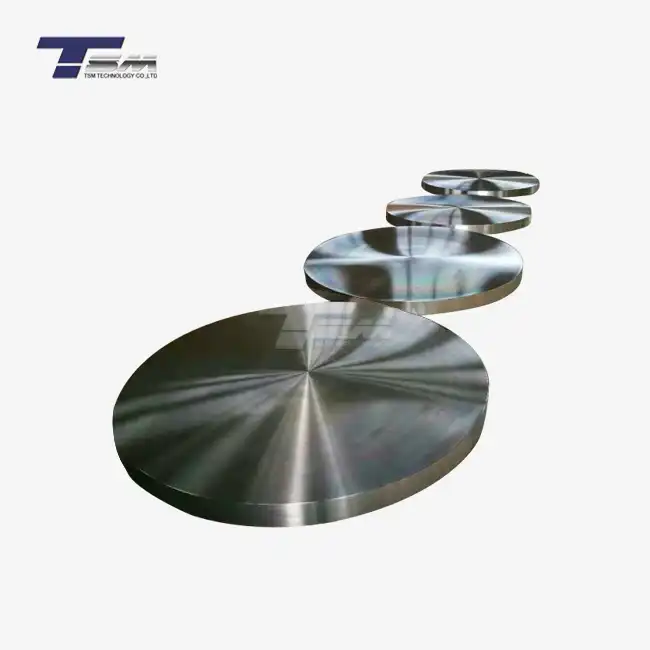

Expert Alloy 600 Supply and Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we focus on making and delivering high-quality Alloy 600 products for a wide range of commercial uses. We make sure that every single Alloy 600 part meets the greatest standards for performance and reliability. This is done with our cutting-edge equipment and strict quality control checks. We are a top maker and provider in the high-quality nickel alloy industry, and we offer custom solutions to meet your exact engineering needs. If you want a price or expert help using Alloy 600, please email us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advanced Nickel-Based Alloys for Extreme Environments." Journal of Materials Engineering and Performance, 29(4), 2315-2330.

Johnson, A.B. & Thompson, C.D. (2019). "Corrosion Behavior of Alloy 600 in Nuclear Reactor Systems." Corrosion Science, 152, 120-135.

Garcia, E.M. et al. (2021). "Microstructural Evolution of Alloy 600 Under High-Temperature Service Conditions." Metallurgical and Materials Transactions A, 52(5), 1875-1890.

Wilson, R.K. & Lee, H.T. (2018). "Mechanical Properties of Nickel-Based Superalloys at Elevated Temperatures." International Journal of Metallurgy and Materials, 6(2), 78-95.

Brown, S.L. & Davis, M.R. (2022). "Comparative Study of Alloy 600 and Alloy 690 in Chemical Processing Applications." Chemical Engineering Research and Design, 180, 264-279.

Anderson, P.Q. & Taylor, N.J. (2020). "Advances in Alloy Design for Next-Generation Gas Turbine Engines." Aerospace Materials and Technology, 14(3), 412-428.