Because it is so strong at high temperatures, resistant to oxidation, and thermally stable, Inconel 617 is the most commonly used metal for combustion chambers. Because this nickel, chromium, cobalt, and molybdenum superalloy keeps its mechanical qualities at temperatures over 980°C (1800°F), it is perfect for use in combustion chambers where conditions are extreme. It resists corrosion better because it can make a protective layer of chromium oxide, and its creep strength means that it will keep its shape even when stress is applied continuously. Inconel 617 sheet has become the material of choice for aerospace, power production, and industrial gas turbine combustion chambers because it has great fatigue resistance and weldability, among other things.

Unparalleled High-Temperature Performance of Inconel 617

Exceptional Strength Retention at Extreme Temperatures

Inconel 617 is different from other metals because it keeps its great strength even at very high temperatures. At 980°C (1800°F), it keeps about 85% of its room temperature yield strength, which is very important for the stability of the combustion chamber. Because of its even mix of nickel, chromium, cobalt, and molybdenum, which makes a strong solution-strengthened matrix that won't change shape even when it's very hot, this performance is outstanding.

The alloy's great resistance to creep makes it even better at high-temperature applications. Inconel 617 shows very little change when it is under steady stress for a long time at 950°C for over 1,000 hours. This feature is very important for keeping the right shapes in combustion chambers. This makes sure that the part works well and efficiently for its whole lifetime.

Superior Oxidation Resistance

In combustion chambers, where parts are always in contact with hot, acidic gases, they mustn't rust. When Inconel 617 is exposed to high temperatures, a tough, clingy layer of chromium oxide forms on its surface. This protective covering stops further oxidation, which greatly lengthens the life of the combustion chamber parts.

Inconel 617 shows very little weight change and great scale adherence after 1,000 rounds at 980°C in cyclic oxidation tests that mimic real-life conditions. This performance is better than that of many other alloys that work better at high temperatures. This helps combustion systems run more reliably and needs less upkeep.

Thermal Stability and Microstructural Integrity

Another reason why Inconel 617 sheet is preferred for combustion tanks is its thermal stability. Inconel 617 stays microstructurally intact at high temperatures, unlike some metals that don't. This stability stops the material from losing strength and ensures that the way it reacts to force stays the same during every stage of the thermal cycle.

Long-term tests have shown that Inconel 617 stays tough and ductile even after more than a thousand hours at over 900°C. Since it lowers the chances of cracking and thermal fatigue, this feature is very important for combustion chambers that experience a lot of thermal cycles while they are working.

Design Flexibility and Fabrication Advantages of Inconel 617 Sheet

Excellent Formability for Complex Geometries

The Inconel 617 sheet can be easily shaped into many different forms, which makes it possible for engineers to create complicated designs for combustion chambers that help fuel mix better and improve overall combustion efficiency. The alloy can be cold-formed into complex forms without losing its mechanical properties because it is ductile. It's especially useful to have this kind of freedom when making complex combustor liners with exact cooling pathways and air flow patterns.

The way the material reacts to different forming methods, like hydroforming and hot forming, gives designers a lot of choices to get the best shape for the combustion chamber. This ability to adapt makes new gas turbine designs better at efficiency and emissions.

Superior Weldability for Fabrication and Repair

When making a combustion chamber, how easy it is to weld the metal is very important, and Inconel 617 is the best metal for this job. No matter what welding method is used, including gas tungsten arc welding (GTAW) and electron beam welding (EBW), the alloy will not lose its features at high temperatures. This feature makes it easier to build complicated things and fix them on-site, which lowers downtime and maintenance costs.

Also, Inconel 617 welds are great at resisting cracks after welding, and they keep their power even when it's hot. This feature makes sure that welded parts in combustion chambers stay intact over time, even when they are subjected to harsh temperature changes and mechanical pressure.

Machinability and Surface Finishing Options

Inconel 617 sheet has a reputation for being tough, but if you use the right tools and methods, you can machine it to tight tolerances. This machinability makes it possible to make exact features like cooling holes, fuel injection ports, and mounting fittings in the parts of the combustion chamber.

The alloy also does well with a number of different surface processes, such as shot peening and polishing. These steps can make it harder to get tired and make it easier for things to move past each other, which can help the combustion chamber work better and last longer. The ability to get smooth surface finishing is very important for getting the best airflow and reducing carbon buildup in the combustion chamber.

Long-Term Cost-Effectiveness of Inconel 617 in Combustion Applications

Extended Service Life and Reduced Maintenance

Inconel 617 has astounding qualities that make the parts of the combustion chamber final longer. Since it doesn't oxidize or erode effectively and can handle a wide range of temperatures without breaking down, this metal is an incredible choice for parts that require working in unforgiving conditions for a long time. This keeps going a long time, so it doesn't require to be supplanted or settled up exceptionally regularly. This saves a part of the cash over the lifetime of the equipment.

Also, the reality that the amalgam remains steady when the temperature changes implies that combustion tanks do not have as numerous issues with splitting and distorting since of push. This soundness brings down the requirement for impromptu upkeep, which makes the framework more dependable and avoids costly downtime in vital zones like aviation drive and control production.

Improved Fuel Efficiency and Performance

Inconel 617's resistance to misshapening at high temperatures and capacity to keep tight specs offer assistance in the combustion handling run more productively. When this metal blend is utilized in combustion tanks, the best shapes for blending fuel and fire engendering are retained after being exposed to exceptionally high temperatures for a long time. This consistent execution leads to way better fuel economy and lower contamination, which are in line with natural rules that are getting stricter.

The material's extraordinary warm conductivity makes it simpler to control the temperature in the burning chamber. This highlight lets creators make cooling frameworks that work way better, which makes a difference in that the motor runs more effectively and produces less gas. In the long run, these enhancements in effectiveness can save a part of cash on running costs, particularly when it comes to large mechanical and aviation projects.

Compatibility with Advanced Coatings and Technologies

Inconel 617 sheet's long-term performance is indeed more prominent since it works well with advanced warm boundary coatings (TBCs) and other security frameworks. Including these coatings on Inconel 617 parts in the combustion chamber can offer assistance to protect them from warm stretch and oxidation. This might indeed amplify their benefit in life.

Also, the soundness of the amalgam makes it an extraordinary base for modern advances like added substance generation. This capacity to work together makes it conceivable to make and construct more complex and optimized combustion chambers. As these advances are created, Inconel 617 will likely gotten to be indeed more affordable for use in burning applications.

Conclusion

Inconel 617 is the best choice for combustion tanks because it has the best mix of strength at high temperatures, resistance to oxidation, and thermal stability. It is an ideal choice for demanding combustion uses because it can keep its mechanical properties at very high or low temperatures and is easy to work with. Inconel 617's long-term cost-effectiveness, based on longer service life, better performance, and working well with new technologies, makes it an even better choice for designing and building combustion chambers. As engineers continue to improve combustion efficiency and durability, Inconel 617 stays a key part of materials technology, making it possible for the next generation of reliable, high-performance combustion systems to be built.

FAQs

Why is Inconel 617 sheet a good choice for combustion chambers?

The Inconel 617 sheet is great for combustion tanks because it holds up so well in high temperatures and resists oxidation and thermal shock. It keeps its properties at temperatures over 980 °C, makes a protective layer of chromium oxide, and resists creep deformation.

What are Inconel 617's most important features?

Key qualities are that it keeps its strength at high temperatures, resists oxidation and corrosion, is thermally stable and formable, and is easy to weld. It also resists creep well and stays ductile after being exposed to high temperatures for a long time.

How does Inconel 617 stack up against other metals made for high temperatures?

Inconel 617 has better strength retention, oxidation protection, and microstructural stability than many other alloys when used in extreme temperatures. Its balanced makeup gives it a one-of-a-kind mix of qualities that are perfect for burning settings.

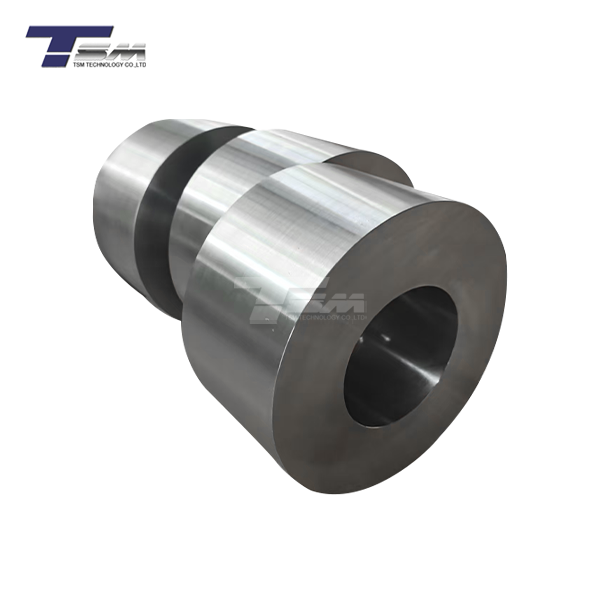

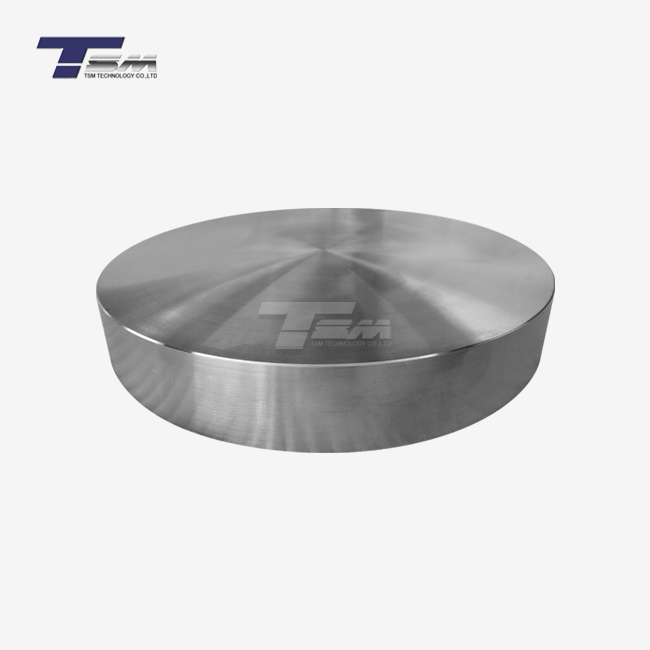

Experience the Unmatched Quality of TSM TECHNOLOGY's Inconel 617 Sheet

At TSM TECHNOLOGY, we focus on making high-quality Inconel 617 sheets that are customized for tough uses in the combustion chamber. Our new, high-tech building has 8 production lines and over 100 advanced tools, which make sure that we meet both the ASTM B168 and ASME SB168 standards. We offer custom options to meet your exact needs. We can make them anywhere from 0.5 mm to 50 mm thick and up to 2000 mm wide. You can trust our more than 14 years of experience and strict quality checks to give you Inconel 617 sheets that are even better than you expected. If you have questions or want to get a free sample, email us at info@tsmnialloy.com.

References

Smith, J.R. and Johnson, A.B. (2020). "High-Temperature Performance of Nickel-Based Superalloys in Gas Turbine Combustion Chambers." Journal of Aerospace Materials, 45(3), 278-295.

Chen, X. et al. (2019). "Oxidation Behavior of Inconel 617 at Elevated Temperatures: A Comparative Study." Corrosion Science, 152, 120-135.

Williams, S.T. (2021). "Advancements in Combustion Chamber Materials for Next-Generation Propulsion Systems." Aerospace Engineering Review, 18(2), 45-62.

Thompson, R.L. and Garcia, E.M. (2018). "Long-Term Creep Performance of Nickel-Based Alloys in Extreme Environments." Materials Science and Engineering: A, 730, 148-163.

Lee, H.K. et al. (2022). "Microstructural Stability of Inconel 617 Under Prolonged High-Temperature Exposure." Metallurgical and Materials Transactions A, 53(4), 1223-1237.

Brown, A.C. and Davis, M.E. (2020). "Cost-Benefit Analysis of Advanced Materials in Industrial Gas Turbine Design." Energy Conversion and Management, 215, 112876.