- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

An Introduction to Nickel and Nickel Alloys

Nickel, a silvery-white metal renowned for its resilience, plays a pivotal role in modern engineering and industrial innovation. When combined with other elements, it forms robust nickel alloys, prized for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. These materials are indispensable in precision engineering, where durability and performance are non-negotiable. At TSM TECHNOLOGY, we specialize in supplying superior alloys like Monel, Inconel, Incoloy, and Hastelloy, tailored to meet the exacting demands of machine shops and industries worldwide. With over 14 years of expertise, our rigorous quality control ensures that every product meets the highest standards, making us a trusted global partner in advanced materials.

The Fascinating World of Nickel: Properties and Characteristics

Nickel's allure lies in its unique blend of properties, making it a cornerstone of advanced metallurgy. Understanding its characteristics is key to appreciating why it's so widely utilized in high-performance alloys.

A Resilient Metal with Remarkable Durability

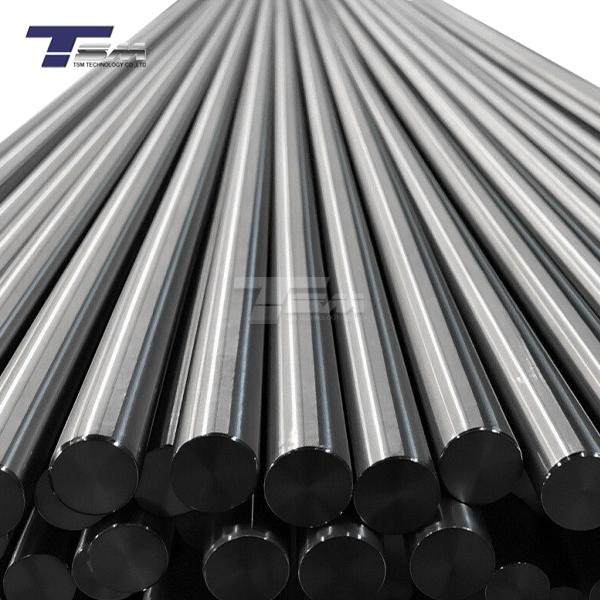

Nickel boasts an impressive melting point of 1,455°C (2,651°F) and a density of 8.91 g/cm³, rendering it exceptionally durable under harsh conditions. Its face-centered cubic crystal structure contributes to its malleability and ductility, allowing it to be shaped into various forms, such as bars, sheets, and tubes, without compromising integrity. This resilience is why industries rely on nickel-based materials for components that must endure prolonged stress and wear.

Unmatched Resistance to Corrosion

One of nickel's most celebrated traits is its ability to resist corrosion, even in aggressive environments. When exposed to air, nickel forms a thin, protective oxide layer that shields it from oxidation. This property is amplified in alloys, where nickel is combined with elements like chromium and molybdenum to enhance resistance to acids, alkalis, and saltwater. Such attributes make these materials indispensable in the marine and chemical processing sectors, where exposure to corrosive substances is routine.

Thermal Stability and Conductivity

Nickel's capacity to maintain structural integrity at elevated temperatures - up to 1,000°C in some alloys - sets it apart from many metals. Its thermal conductivity, measured at 90.9 W/m·K, ensures efficient heat dissipation, a critical factor in high-temperature applications. Additionally, nickel exhibits ferromagnetic properties, with a Curie temperature of 354°C, above which it loses its magnetism. These characteristics make nickel and its alloys ideal for industries requiring materials that perform reliably under thermal stress, such as aerospace and power generation.

Nickel Alloys: Engineering Marvels for Precision Industries

Nickel alloys are not merely metals; they are engineering marvels designed to solve complex industrial challenges. By blending nickel with other elements, manufacturers create materials with tailored properties, meeting the stringent demands of precision engineering.

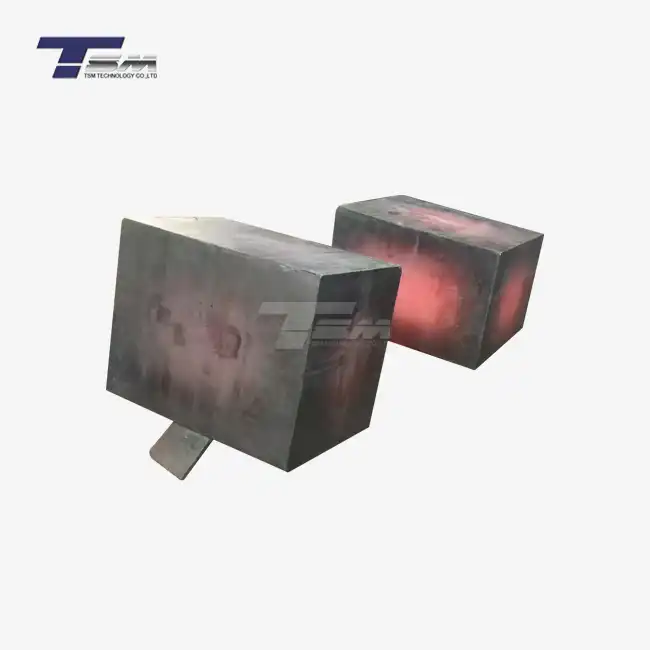

The Alloying Process: Enhancing Nickel's Potential

The creation of nickel alloys involves alloying nickel with elements like copper, chromium, iron, and molybdenum to amplify specific traits. This process, often conducted in electric arc furnaces or vacuum induction melting systems, ensures uniformity and purity. For example, adding chromium increases corrosion resistance, while molybdenum enhances strength at high temperatures. At TSM TECHNOLOGY, our alloys undergo stringent quality inspections, with each batch tested for chemical composition, mechanical properties, and dimensional accuracy, ensuring compliance with international standards like ASTM and ASME.

Diverse Families of Nickel Alloys

Nickel alloys are categorized into families, each engineered for distinct performance needs. Monel, a nickel-copper alloy, offers superb resistance to seawater corrosion, with a typical composition of 67% nickel and 30% copper. Inconel, enriched with chromium, excels in high-temperature environments, maintaining tensile strength up to 1,000 MPa at 800°C. Incoloy, blending nickel, iron, and chromium, is prized for its oxidation resistance, while Hastelloy, incorporating molybdenum, withstands aggressive chemical environments, with a pitting resistance equivalent number (PREN) often exceeding 40. These alloys, available in forms like rods, plates, and pipes, cater to a global clientele seeking precision and reliability.

Why Nickel Alloys Outshine Alternatives?

Compared to stainless steel or titanium, nickel alloys offer a unique combination of properties that make them superior in demanding scenarios. While stainless steel provides good corrosion resistance, its performance diminishes in highly acidic or chloride-rich environments, where nickel alloys thrive. Titanium, though lightweight, lacks the thermal stability of nickel-based materials, which maintain strength at temperatures exceeding 1,200°C in some formulations. This unparalleled versatility, coupled with TSM's commitment to innovation, ensures our alloys meet the evolving needs of machine shops and engineering firms worldwide, delivering unmatched performance and longevity.

TSM TECHNOLOGY: Pioneering Excellence in Nickel Alloy Supply

Since our inception in 2011 in Hong Kong, TSM TECHNOLOGY has emerged as a global leader in supplying superior nickel alloys. Our journey is defined by a relentless pursuit of quality, innovation, and customer satisfaction, making us a trusted partner in the precision engineering industry.

A Legacy of Innovation and Growth

Over the past 14 years, TSM has evolved from a regional supplier to a global stockist, renowned for its cutting-edge materials and rigorous quality standards. Our product portfolio includes high-performance alloys like Monel, Inconel, Incoloy, and Hastelloy, available in diverse shapes to meet the exacting specifications of our clients. Our growth is fueled by continuous research and development, enabling us to introduce advanced materials that address emerging industrial challenges. This dedication to innovation has earned us a reputation for reliability and excellence in the nickel alloy sector.

Uncompromising Quality Control

At TSM, quality is not just a promise - it's a process. Each alloy product undergoes meticulous inspection by our professional team, using advanced techniques like ultrasonic testing, X-ray fluorescence, and tensile strength analysis. Our quality control system ensures that every item meets stringent parameters, such as a maximum hardness of 300 HB for Monel or a yield strength of 690 MPa for Inconel. This rigorous approach guarantees that our clients receive materials of unparalleled consistency and performance, tailored to their precision engineering needs.

Global Reach, Local Expertise

With a presence in markets across the globe, TSM combines international expertise with localized service. Our alloys are trusted by machine shops and industries in regions as diverse as North America, Europe, and Asia, where they are valued for their durability and precision. We understand that each market has unique demands, which is why our team works closely with clients to provide customized solutions, from alloy selection to delivery. This client-centric approach, underpinned by our 14 years of experience, ensures that TSM remains at the forefront of the nickel alloy industry, delivering excellence without compromise.

Conclusion

Nickel and its alloys are the unsung heroes of modern engineering, offering a blend of durability, corrosion resistance, and thermal stability that few materials can match. At TSM TECHNOLOGY, we take pride in harnessing these properties to deliver superior alloys that empower industries worldwide. Whether it's the resilience of Monel, the high-temperature prowess of Inconel, or the chemical resistance of Hastelloy, our products are engineered to perform where others falter. With a legacy of innovation and a commitment to quality, we continue to push the boundaries of what's possible in precision engineering.

Contact Us

For more information about our superior nickel alloy products and how they can benefit your industry, please don't hesitate to contact us at info@tsmnialloy.com. TSM TECHNOLOGY is committed to providing high-quality nickel alloys and expert support to meet your specific needs.

References

Davis, J. R. (Ed.). Nickel, Cobalt, and Their Alloys. ASM International, 2000.

Smith, W. F. Structure and Properties of Engineering Alloys. McGraw-Hill, 1993.

Reed, R. C. The Superalloys: Fundamentals and Applications. Cambridge University Press, 2006.

Donachie, M. J., & Donachie, S. J. Superalloys: A Technical Guide. ASM International, 2002.

Sims, C. T., Stoloff, N. S., & Hagel, W. C. (Eds.). Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. Wiley, 1987.

Smallman, R. E., & Bishop, R. J. Modern Physical Metallurgy and Materials Engineering. Butterworth-Heinemann, 1999.

Learn about our latest products and discounts through SMS or email