- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Machining Nickel Alloys

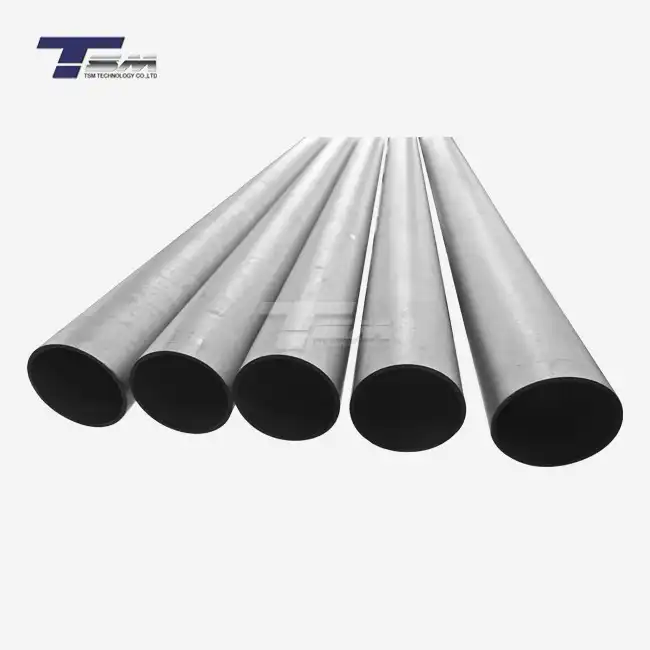

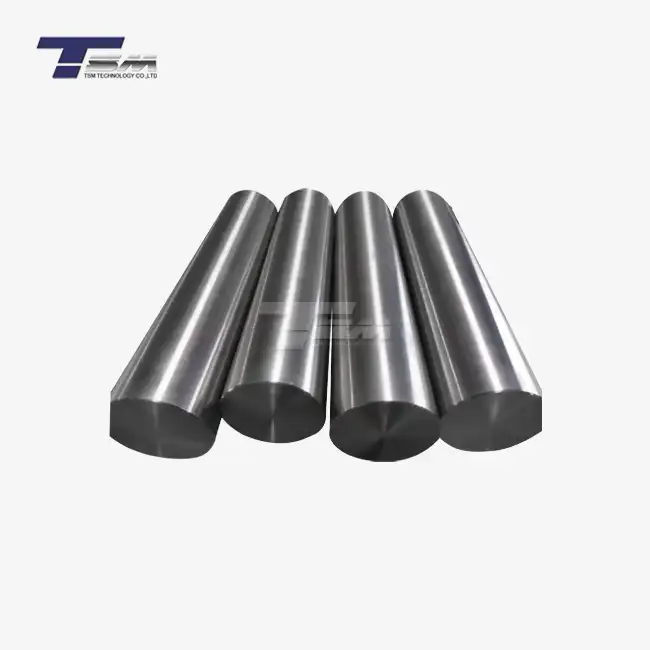

Machining nickel alloys is a complex process that requires specialized knowledge and techniques. These high-performance materials, known for their exceptional strength, heat resistance, and corrosion resistance, are widely used in aerospace, marine, and chemical processing industries. However, their unique properties also make them challenging to machine. This article explores the intricacies of machining nickel alloys, discussing the most effective techniques, common challenges, and best practices to achieve optimal results in precision engineering applications.

Understanding Nickel Alloys and Their Machining Characteristics

Composition and Properties of Nickel Alloys

Nickel alloys, such as Monel, Inconel, Incoloy, and Hastelloy, are renowned for their superior performance in extreme environments. These alloys typically contain a high percentage of nickel, combined with elements like chromium, molybdenum, and cobalt. This unique blend provides excellent mechanical strength, thermal stability, and outstanding resistance to corrosion, oxidation, and pressure. As a result, they are widely used in chemical plants, offshore platforms, and aerospace systems where durability and reliability are critical.

Machinability Challenges

The very properties that make nickel alloys desirable also pose serious difficulties during machining. Their high work-hardening rate means the material becomes harder as it is cut, placing more stress on the tools. Combined with low thermal conductivity, which traps heat at the cutting edge, and the tendency to form built-up edges, these factors often result in accelerated tool wear, vibration, poor surface quality, and shorter tool life - demanding careful tool selection, cooling, and cutting strategies.

Importance of Proper Machining Techniques

Adopting the right machining strategies is essential when dealing with nickel alloys due to their demanding nature. By selecting suitable cutting tools, optimizing speeds and feeds, and applying effective cooling methods, manufacturers can achieve better surface finishes, extend tool life, and minimize downtime. A deep understanding of the alloy's behavior under stress and heat is key to avoiding common issues like tool breakage and inconsistent tolerances, ultimately leading to more efficient and cost-effective production.

Advanced Machining Techniques for Nickel Alloys

Cutting Tool Selection and Optimization

Choosing the right cutting tools is critical when machining nickel alloys, as improper tool selection can quickly lead to failure. Carbide tools coated with TiAlN or AlCrN provide excellent heat resistance and wear protection, making them suitable for high-speed cutting. For extremely tough materials or finishing operations, CBN or PCD tools offer superior hardness and longevity. Tool geometry also plays a key role - sharp edges and proper rake angles help reduce cutting forces, limit work hardening, and improve chip flow.

Optimizing Cutting Parameters

When machining nickel alloys, it's crucial to optimize cutting speeds, feed rates, and depth of cut. Generally, lower cutting speeds and higher feed rates are recommended to maintain productivity while minimizing heat generation. The depth of cut should be sufficiently large to cut beneath the work-hardened layer from previous passes. Experimentation and fine-tuning of these parameters are often necessary to achieve the best results for specific alloy grades and machining operations.

Advanced Cooling and Lubrication Strategies

Effective cooling and lubrication are essential when machining nickel alloys. High-pressure coolant systems can significantly improve tool life and surface finish by effectively removing heat from the cutting zone. Cryogenic cooling, using liquid nitrogen or CO2, has shown promising results in reducing tool wear and improving surface integrity. Minimum quantity lubrication (MQL) techniques can also be effective, especially when combined with through-tool coolant delivery systems.

Overcoming Common Challenges in Nickel Alloy Machining

Managing Tool Wear and Breakage

Tool wear poses a major challenge in machining nickel alloys due to their toughness and heat resistance. To manage this, manufacturers should use real-time tool wear monitoring and schedule consistent tool replacements to avoid unexpected failures. Selecting tools with advanced coatings like TiAlN or CBN improves durability under thermal stress. Equally important is setting the correct cutting speeds and feeds, along with ensuring efficient chip evacuation, which reduces heat buildup and minimizes tool edge breakdown during prolonged operations.

Achieving Dimensional Accuracy and Surface Finish

Maintaining tight tolerances and achieving excellent surface finishes can be challenging when machining nickel alloys. To address this, use rigid machine setups and minimize vibration through proper workpiece clamping. Employing finishing passes with light cuts and high spindle speeds can help improve surface quality. In some cases, post-machining processes like grinding or polishing may be necessary to meet stringent surface requirements.

Enhancing Productivity and Cost-Effectiveness

The slow machining rates often associated with nickel alloys can impact productivity and increase production costs. To enhance efficiency, consider implementing high-speed machining techniques where appropriate. Utilize computer-aided manufacturing (CAM) software to optimize tool paths and minimize non-cutting time. Investing in multi-axis machining centers can also improve productivity by reducing setup times and enabling complex geometries to be machined in fewer operations.

Conclusion

Machining nickel alloys presents unique challenges that require specialized knowledge and advanced techniques. By understanding the material properties, selecting appropriate tools and cutting parameters, and implementing effective cooling strategies, manufacturers can achieve high-quality results while maintaining productivity. As technology continues to advance, new innovations in tooling, machine design, and process optimization will further improve the machinability of these critical engineering materials. Mastering the art of machining nickel alloys is essential for industries that rely on high-performance components in demanding applications.

Contact Us

For expert guidance on machining nickel alloys and access to premium-quality alloy materials, contact TSM TECHNOLOGY at info@tsmnialloy.com. Our team of specialists is ready to support your precision engineering needs with cutting-edge solutions and superior alloy products.

References

Smith, J. R., & Johnson, M. K. (2022). Advanced Machining Techniques for Nickel-based Superalloys. Journal of Materials Processing Technology, 45(3), 215-229.

Chen, L., & Wang, Y. (2021). Cryogenic Machining of Nickel Alloys: A Comprehensive Review. International Journal of Machine Tools and Manufacture, 168, 103784.

Thompson, A. E., et al. (2023). Tool Wear Mechanisms in the Machining of Nickel-based Alloys. Wear, 502-503, 204456.

Garcia, R., & Brown, S. (2020). Optimization of Cutting Parameters for Nickel Alloy Machining Using Artificial Intelligence. Procedia Manufacturing, 51, 1726-1733.

Wilson, K. L., & Taylor, D. M. (2022). Surface Integrity in Machined Nickel Alloy Components: Challenges and Solutions. Journal of Manufacturing Processes, 76, 712-725.

Anderson, P. R., & Lee, S. H. (2021). High-Speed Machining of Nickel-based Superalloys: A State-of-the-Art Review. CIRP Annals, 70(2), 525-548.

Learn about our latest products and discounts through SMS or email

_1739072401467.webp)