- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

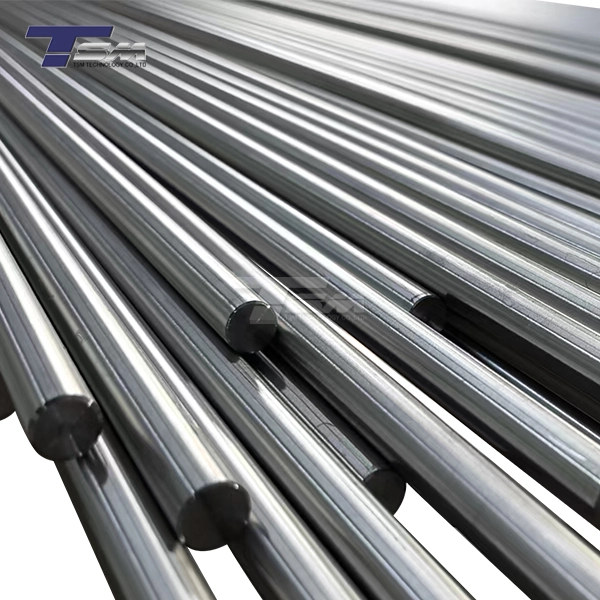

An Overview of Inconel 600 Round Bars: Properties and Applications

When selecting materials for extreme operating conditions, Inconel 600 round bars stand out as a premium nickel-chromium alloy solution. This versatile material combines exceptional oxidation resistance, superior corrosion protection, and remarkable high-temperature strength, making it indispensable across demanding industrial applications. Composed primarily of nickel (72% minimum) and chromium (14-17%), these round bars maintain structural integrity in environments where conventional materials fail. Whether facing corrosive chemicals, extreme heat, or aggressive atmospheres, this nickel-based superalloy delivers reliable performance. Engineers and procurement specialists worldwide trust this material for critical applications in chemical processing, heat treatment equipment, nuclear reactors, and aerospace systems where failure is not an option.

Understanding Inconel 600: Composition and Core Properties

Chemical Composition and Metallurgical Structure

The foundation of Inconel 600's exceptional performance lies in its carefully balanced chemical composition. This nickel-chromium alloy contains a minimum of 72% nickel, 14-17% chromium, and 6-10% iron, with trace amounts of manganese, silicon, copper, and carbon. The high nickel content provides outstanding resistance to chloride-ion stress-corrosion cracking, while chromium delivers superior oxidation resistance at elevated temperatures. This austenitic structure remains stable across a broad temperature range, preventing phase transformations that could compromise material integrity. The metallurgical makeup creates a face-centered cubic crystal structure that resists embrittlement and maintains ductility even after prolonged exposure to challenging environments.

Mechanical Properties at Various Temperatures

Inconel 600 round bars manufactured from this superalloy exhibit impressive mechanical characteristics across temperature extremes. At room temperature, the material demonstrates a tensile strength ranging from 550-750 MPa and yield strength of 240-450 MPa, providing robust structural capabilities. What distinguishes this alloy is its retention of strength at elevated temperatures - maintaining approximately 90% of its room-temperature strength at 540°C (1000°F). The elongation percentage typically exceeds 30%, indicating excellent ductility and formability. These mechanical properties make the material suitable for components subjected to thermal cycling, mechanical stress, and dynamic loading conditions without premature failure or deformation.

Corrosion Resistance Characteristics

The corrosion resistance profile of these round bars sets them apart in hostile chemical environments. The alloy demonstrates exceptional resistance to organic acids, alkaline solutions, and neutral salts. Particularly noteworthy is its performance in reducing atmospheres where chromium-based alloys often struggle. The material resists attack from ammonia gas, halogen gases, and numerous organic compounds. The passive oxide film that forms on the surface provides self-healing protection against pitting and crevice corrosion. This corrosion resistance extends to both aqueous and gaseous environments, making it versatile for diverse industrial applications where material degradation would compromise safety and operational efficiency.

Key Properties of Inconel 600 Round Bars

High-Temperature Performance and Oxidation Resistance

These cylindrical products excel in high-temperature environments where many materials experience rapid degradation. The alloy maintains structural stability up to 1093°C (2000°F) in oxidizing conditions, with continuous service temperatures reaching 1150°C (2100°F) for shorter durations. The chromium content forms a tenacious chromium oxide layer that prevents further oxidation and scaling. Unlike carbon steel or stainless steel alternatives, these round bars resist carburization and nitriding in process atmospheres containing carbon or nitrogen. The material exhibits minimal creep deformation under sustained loads at elevated temperatures, ensuring dimensional stability in furnace components, heat exchangers, and thermal processing equipment throughout extended service life.

Fabrication and Machining Characteristics

Working with Inconel 600 round bar requires understanding its unique fabrication behavior. The material work-hardens rapidly during cold working operations, necessitating intermediate annealing cycles for extensive forming. Hot working temperatures between 870-1230°C (1600-2250°F) provide optimal formability. Machining these round bars demands carbide or high-speed steel tooling with positive rake angles and adequate coolant flow. Recommended cutting speeds are approximately 50-60% of those used for mild steel. Welding can be accomplished using gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW) techniques with matching filler metals. Solution annealing at 900-1050°C followed by rapid cooling restores optimal corrosion resistance after fabrication, ensuring component performance meets specification requirements.

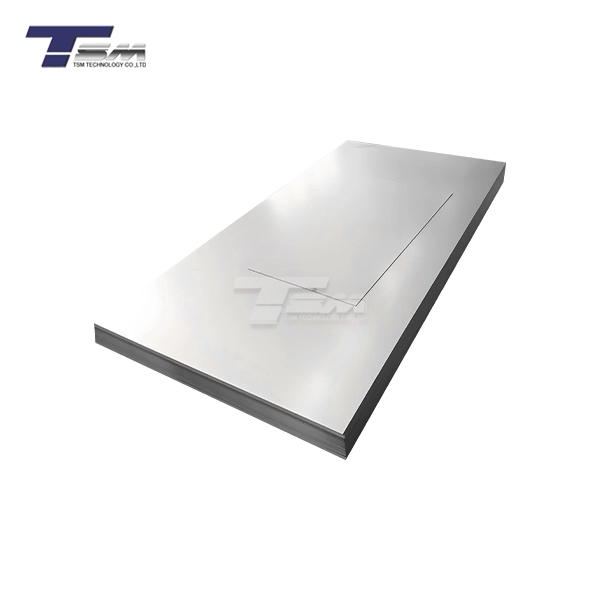

Physical Properties and Specifications

The physical characteristics of these round bars contribute significantly to their application suitability. The material density measures 8.47 g/cm³, providing substantial mass for structural applications. The melting range spans 1354-1413°C (2470-2575°F), well above typical operating temperatures. Thermal conductivity at 100°C is approximately 14.8 W/m·K, offering moderate heat transfer capabilities. The coefficient of thermal expansion measures 13.3 μm/m·°C (20-100°C), requiring consideration in precision assemblies. These round bars are available in various diameters ranging from 6mm to 300mm, with standard lengths up to 6 meters. Surface finishes include hot-rolled, cold-drawn, peeled, and polished conditions, each suited to different application requirements and precision tolerances.

Industrial Applications and Use Cases

Chemical Processing and Petrochemical Industries

The chemical processing sector relies heavily on Inconel 600 round bars for equipment handling corrosive media. They serve as feedstock for manufacturing reactor vessels, heat exchanger tubing, condenser tubes, and distillation column internals. The material's resistance to chloride stress-corrosion cracking makes it invaluable in chlor-alkali production facilities. Petrochemical plants utilize these components in catalytic reforming units, hydrocarbon processing systems, and sulfuric acid manufacturing equipment. The round bars are machined into valve stems, pump shafts, and agitator shafts where mechanical strength must combine with corrosion resistance. In environments containing fluorine, hydrofluoric acid, or mixed acids, this alloy often outperforms alternative materials, reducing maintenance costs and unplanned downtime.

Heat Treatment and Furnace Applications

Thermal processing industries depend on these round bars for critical furnace components and heat treatment equipment. They are fabricated into radiant tubes, muffles, retorts, and fixtures exposed to combustion gases and extreme temperatures. The oxidation resistance prevents scaling that would contaminate processed materials or reduce heat transfer efficiency. Manufacturers produce baskets, trays, and support structures from these bars for sintering, annealing, and brazing operations. The material maintains mechanical strength under thermal cycling conditions that cause conventional alloys to fail prematurely. Carburizing and nitriding furnace components benefit from the alloy's resistance to carbon and nitrogen absorption, maintaining dimensional accuracy and extending service intervals between replacements.

Nuclear and Aerospace Applications

Critical industries with stringent performance requirements specify these round bars for specialized components. Nuclear power generation facilities utilize the material for steam generator tubing, control rod components, and reactor core structural elements. The combination of corrosion resistance, mechanical strength, and radiation stability makes it suitable for primary and secondary coolant systems. Aerospace applications include turbine engine components, exhaust systems, and fasteners requiring high-temperature stability. The round bars are machined into specialized fasteners, springs, and structural elements for aircraft and spacecraft operating in extreme environments. The aerospace sector values the material's proven reliability, extensive performance data, and compliance with rigorous quality standards essential for safety-critical applications.

Conclusion

Inconel 600 round bars represent a proven engineering solution for the most demanding industrial environments. Their exceptional combination of high-temperature strength, corrosion resistance, and oxidation stability makes them irreplaceable in chemical processing, thermal systems, and critical aerospace applications. Understanding the material's composition, mechanical properties, and fabrication characteristics enables engineers to optimize component design and material selection. While the initial investment exceeds conventional materials, the extended service life, reduced maintenance requirements, and superior reliability deliver compelling lifecycle value. As industries continue pushing operational boundaries with higher temperatures, more aggressive chemicals, and stricter safety standards, these nickel-chromium alloy round bars remain essential for engineering excellence and operational success.

FAQs

What temperature range can Inconel 600 round bars withstand?

These alloy bars perform continuously at temperatures up to 1093°C (2000°F) in oxidizing environments, with short-term exposure capabilities reaching 1150°C (2100°F). They maintain excellent mechanical properties from cryogenic temperatures through their maximum service range.

How does Inconel 600 compare to stainless steel for corrosion resistance?

This nickel-based superalloy significantly outperforms austenitic stainless steels in chloride environments, reducing atmospheres, and high-temperature oxidation. It resists stress-corrosion cracking where stainless steels fail, particularly in chloride-containing solutions.

Can these round bars be welded?

Absolutely. Welding is readily accomplished using GTAW or GMAW processes with matching composition filler metals. Proper technique and post-weld heat treatment ensure weld zones maintain the base material's corrosion resistance and mechanical properties.

Get Premium Inconel 600 Round Bars from TSM TECHNOLOGY

TSM Technology Co., Ltd. stands as your reliable partner for superior quality nickel alloy products. As experienced manufacturers and stockists with over 14 years of international trading expertise, we supply precision-engineered round bars meeting the strictest quality standards. Our comprehensive inspection system ensures every product delivers the performance your critical applications demand. Whether you need standard sizes or custom specifications, our technical team provides expert guidance from material selection through delivery. Contact our specialists today at info@tsmnialloy.com to discuss your project requirements and experience the TSM advantage in superior alloy supply.

References

Davis, J.R. (2000). Nickel, Cobalt, and Their Alloys. ASM International, Materials Park, Ohio.

Lai, G.Y. (2007). High-Temperature Corrosion and Materials Applications. ASM International, Materials Park, Ohio.

Special Metals Corporation. (2008). Technical Bulletin: Inconel Alloy 600. Engineering Properties and Applications Guide.

Donachie, M.J. and Donachie, S.J. (2002). Superalloys: A Technical Guide, 2nd Edition. ASM International.

Craig, B.D. and Anderson, D.S. (1995). Handbook of Corrosion Data, 2nd Edition. ASM International, Materials Park, Ohio.

Sims, C.T., Stoloff, N.S., and Hagel, W.C. (1987). Superalloys II: High-Temperature Materials for Aerospace and Industrial Power. John Wiley & Sons, New York.

Learn about our latest products and discounts through SMS or email