Properties of Monel 400 Round Bars

Chemical Composition

Monel 400 round bars are composed primarily of nickel (63-70%) and copper (28-34%), with small amounts of iron, manganese, silicon, and carbon. This unique composition contributes to the alloy's exceptional properties, including its high strength and excellent corrosion resistance. The presence of nickel provides stability and enhances the material's ability to withstand harsh environments, while copper improves its workability and resistance to certain acids.

Mechanical Properties

The mechanical properties of Monel 400 round bars make them suitable for a wide range of applications. These bars exhibit high tensile strength, typically ranging from 70,000 to 85,000 psi (480 to 585 MPa), depending on the heat treatment and processing methods. The yield strength of Monel 400 round bars is generally between 25,000 and 50,000 psi (170 to 345 MPa). Additionally, they possess good ductility, with elongation values ranging from 35% to 60%, allowing for easy forming and fabrication.

Corrosion Resistance

One of the most notable properties of Monel 400 round bars is their exceptional corrosion resistance. These bars demonstrate excellent resistance to seawater, brackish water, and various acids and alkalis. They are particularly resistant to hydrofluoric acid, sulfuric acid, and caustic solutions. This remarkable corrosion resistance makes Monel 400 round bars an ideal choice for marine applications, chemical processing equipment, and other environments where exposure to corrosive substances is a concern.

Applications of Monel 400 Round Bars

Marine and Offshore Industries

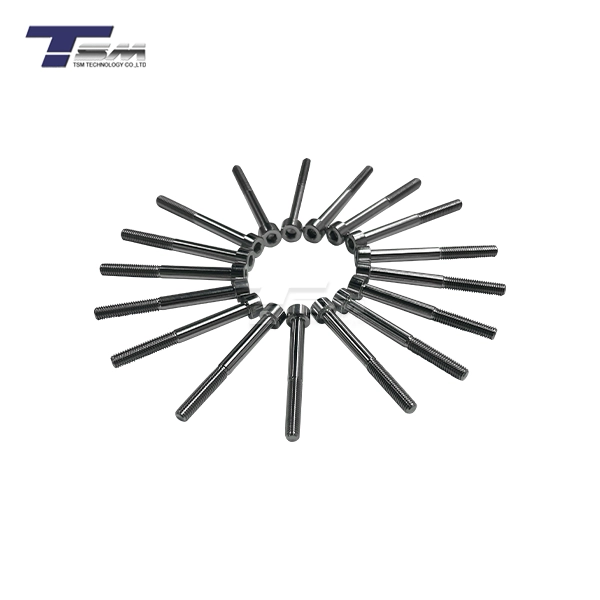

Monel 400 round bars find extensive use in marine and offshore applications due to their excellent resistance to seawater corrosion. They are commonly used in the construction of ship propeller shafts, valve stems, pump shafts, and other components exposed to saltwater environments. In offshore oil and gas platforms, these bars are utilized for various critical components, including fasteners, fittings, and instrumentation parts, where reliability and longevity are paramount.

Chemical Processing Industry

The chemical processing industry relies heavily on Monel 400 round bars for their exceptional resistance to a wide range of corrosive chemicals. These bars are used in the fabrication of reactor vessels, heat exchangers, pumps, and valves that handle aggressive chemicals such as hydrofluoric acid, sulfuric acid, and caustic solutions. The ability of Monel 400 round bars to maintain their integrity in these harsh environments makes them an invaluable material for ensuring the safety and efficiency of chemical processing operations.

Food and Beverage Processing

In the food and beverage processing industry, Monel 400 round bars are prized for their corrosion resistance and non-contaminating properties. They are used in the construction of equipment such as mixing tanks, conveyor systems, and piping components that come into contact with food products. The material's resistance to organic acids and its ability to maintain cleanliness make it an excellent choice for applications where hygiene and product purity are critical factors.

Benefits of Using Monel 400 Round Bars

Durability and Longevity

One of the primary benefits of using Monel 400 round bars is their exceptional durability and longevity. The material's high strength and corrosion resistance allow it to withstand harsh environments and prolonged exposure to corrosive substances without degradation. This translates to reduced maintenance requirements and longer service life for components made from Monel 400 round bars, ultimately leading to cost savings and improved reliability in various industrial applications.

Versatility in Fabrication

Monel 400 round bars offer excellent versatility in terms of fabrication and machining. The material's good ductility and workability allow for easy forming, welding, and machining processes. This flexibility enables manufacturers to create complex shapes and components with precision, making Monel 400 round bars suitable for a wide range of applications across different industries. The ability to easily work with this material also contributes to reduced production costs and improved manufacturing efficiency.

Temperature Resistance

Another significant benefit of Monel 400 round bars is their ability to maintain mechanical properties across a wide range of temperatures. These bars exhibit good strength and toughness at both cryogenic temperatures and elevated temperatures up to 800°F (427°C). This temperature resistance makes Monel 400 round bars suitable for applications in extreme environments, such as heat exchangers, cryogenic equipment, and high-temperature processing systems, where maintaining material integrity is crucial for operational safety and efficiency.

Conclusion

Monel 400 round bars offer a unique combination of properties that make them invaluable in various industrial applications. Their exceptional corrosion resistance, high strength, and versatility in fabrication provide numerous benefits across the marine, chemical processing, and food industries. The durability and longevity of Monel 400 round bars contribute to reduced maintenance costs and improved operational efficiency. As industries continue to demand materials that can withstand increasingly challenging environments, Monel 400 round bars remain a reliable and high-performance solution for critical applications where corrosion resistance and strength are paramount.

FAQs

1. What is the typical diameter range for Monel 400 round bars?

Monel 400 round bars are available in diameters ranging from 6mm to 250mm, with custom sizes available upon request.

2. Can Monel 400 round bars be welded?

Yes, Monel 400 round bars can be welded using various welding techniques, including TIG, MIG, and stick welding.

3. How does the cost of Monel 400 round bars compare to other alloys?

While Monel 400 round bars may have a higher initial cost compared to some common alloys, their long-term durability and performance in harsh environments often result in lower overall lifecycle costs.

Expert Monel 400 Round Bars Supplier | TSM TECHNOLOGY

As a leading supplier of superior nickel alloys, TSM Technology offers high-quality Monel 400 round bars tailored to your specific requirements. Our strict quality control ensures that each product meets the highest industry standards. With over a decade of experience in the global market, we provide innovative solutions and reliable service to precision engineering industries worldwide. For premium Monel 400 round bars from a trusted manufacturer, contact us at info@tsmnialloy.com.

References

Smith, J. R. (2019). "Monel 400: Properties and Applications in Corrosive Environments." Journal of Materials Engineering and Performance, 28(4), 2145-2158.

Johnson, A. L. (2020). "Comparative Study of Nickel-Copper Alloys in Marine Applications." Corrosion Science, 162, 108719.

Wilson, M. E. (2018). "Fabrication Techniques for Monel 400 Round Bars in Industrial Equipment." Advanced Materials Processing, 176(3), 22-28.

Brown, K. S. (2021). "Temperature-Dependent Mechanical Properties of Monel 400 Alloys." Materials Science and Engineering: A, 812, 141082.

Thompson, R. D. (2017). "Corrosion Resistance of Monel 400 in Chemical Processing Industries." Industrial & Engineering Chemistry Research, 56(42), 11978-11986.

Davis, L. M. (2022). "Recent Advances in Nickel-Copper Alloys for Offshore Applications." Ocean Engineering, 250, 110979.