Exceptional Properties of Incoloy 800 Tubes for Petrochemical Applications

High-Temperature Strength and Durability

Incoloy 800 tubes are engineered to provide exceptional strength and stability even under extreme thermal conditions, making them ideal for demanding petrochemical processes involving high temperatures. The alloy’s carefully balanced composition allows it to maintain structural integrity during prolonged exposure to heat, minimizing the risk of equipment deformation, failure, or operational interruptions. This high-temperature durability ensures reliable performance over extended service periods, contributing to safer, more efficient operations and a longer operational lifespan for reactors, heat exchangers, and other critical petrochemical equipment.

Superior Corrosion Resistance

Incoloy 800 pipes excel in the highly aggressive environments commonly found in petrochemical plants. The alloy demonstrates outstanding resistance to oxidation, sulfidation, and carburization, which are frequent challenges in petroleum refining and chemical processing operations. Its superior corrosion resistance prevents material degradation, extending the service life of critical equipment. By mitigating the impact of corrosive elements, Incoloy 800 significantly reduces maintenance requirements, downtime, and operational costs, making it a reliable material choice for piping, heat exchangers, and other components exposed to harsh chemical and thermal environments.

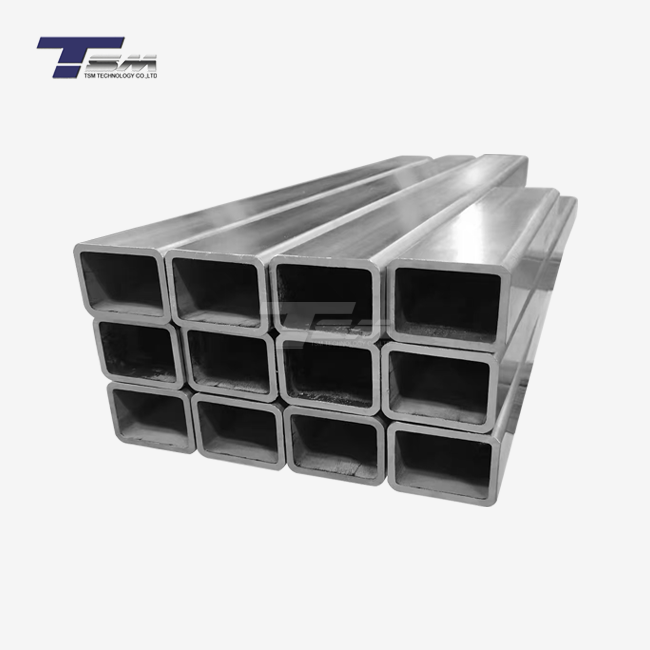

Excellent Fabrication Properties

Incoloy 800 tubes offer excellent versatility for fabrication, making them highly adaptable for complex petrochemical systems. The alloy can be welded, formed, and machined with relative ease, allowing engineers to design custom equipment that meets specific process requirements. This ease of fabrication ensures precise integration into reactors, piping networks, and heat exchangers, enhancing operational efficiency and reliability. The combination of mechanical robustness, corrosion resistance, and manufacturability allows Incoloy 800 to support high-performance petrochemical operations while maintaining long-term durability and reducing overall maintenance efforts.

Key Applications of Incoloy 800 Tubes in Petrochemical Processes

Heat Exchangers and Boilers

Incoloy 800 pipes are extensively used in heat exchangers and boilers within petrochemical plants. Their exceptional thermal conductivity and resistance to high-temperature corrosion make them ideal for transferring heat efficiently in various processes, including distillation, cracking, and reforming. The tubes' ability to withstand thermal cycling and maintain their properties over time ensures reliable performance in these critical applications.

Ethylene Production Systems

In ethylene production, Incoloy 800 tubes are crucial components of furnace quench systems. These systems rapidly cool the hot gases produced during the cracking process, and Incoloy 800 pipes can withstand the severe thermal shock and corrosive environments associated with this application. Their use in ethylene furnaces contributes to improved process efficiency and extended equipment life.

Petrochemical Processing Equipment

Incoloy 800 tubes find wide application in various petrochemical processing equipment, including reactors, distillation columns, and piping systems. The alloy's resistance to a broad range of chemicals and its ability to maintain strength at high temperatures make it an excellent choice for handling diverse petrochemical streams. This versatility allows for the design of robust and efficient processing units across the petrochemical industry.

Advantages of Using Incoloy 800 Tubes in the Petrochemical Industry

Enhanced Process Efficiency

The use of Incoloy 800 pipes in petrochemical applications leads to significant improvements in process efficiency. Their superior heat transfer properties and resistance to fouling allow for more effective heat exchange, reducing energy consumption and improving overall plant performance. Additionally, the alloy's durability minimizes downtime for maintenance and repairs, contributing to increased productivity.

Cost-Effective Long-Term Solution

While the initial investment in Incoloy 800 tubes may be higher compared to some alternatives, their long-term benefits make them a cost-effective choice for petrochemical operations. The extended service life, reduced maintenance requirements, and improved process efficiency result in substantial cost savings over time. This makes Incoloy 800 pipes an economically viable solution for petrochemical plants seeking to optimize their operations and reduce lifecycle costs.

Compliance with Industry Standards

Incoloy 800 tubes manufactured to international standards such as ASTM B163, ASTM B704, and ASTM B407 ensure compliance with rigorous industry requirements. This adherence to established standards provides petrochemical companies with confidence in the quality and reliability of the materials used in their critical processes. It also simplifies the specification and procurement processes, streamlining project implementation and maintenance activities.

Conclusion

Incoloy 800 tubes have become indispensable in the petrochemical industry due to their exceptional properties and versatile applications. From heat exchangers and ethylene production systems to various processing equipment, these high-performance pipes contribute significantly to the efficiency, reliability, and longevity of petrochemical operations. As the industry continues to evolve and face new challenges, the role of Incoloy 800 tubes in ensuring safe, efficient, and cost-effective processes is likely to grow even further, cementing their position as a critical material in petrochemical engineering.

FAQs

What are the key advantages of using Incoloy 800 tubes in petrochemical applications?

Incoloy 800 tubes offer exceptional high-temperature strength, superior corrosion resistance, and excellent fabrication properties, making them ideal for demanding petrochemical environments.

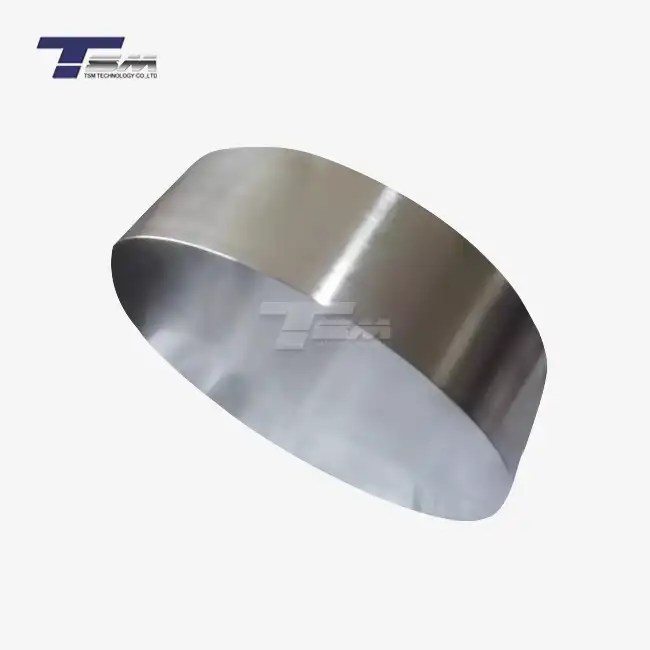

What are the typical dimensions of Incoloy 800 pipes available for petrochemical use?

Incoloy 800 tubes are available in outside diameters ranging from 6.0 to 114 mm, with wall thicknesses from 0.5 to 15 mm. Custom sizes can be produced to meet specific requirements.

How do Incoloy 800 tubes contribute to cost savings in petrochemical plants?

While initially more expensive, Incoloy 800 pipes offer long-term cost savings through extended service life, reduced maintenance needs, and improved process efficiency in petrochemical operations.

Applications of Incoloy 800 Tube in the Petrochemical Industry | TSM TECHNOLOGY

TSM Technology, a leading Incoloy 800 tube manufacturer and supplier since 2011, offers high-quality pipes for petrochemical applications. With state-of-the-art production facilities and strict quality control, we provide customized solutions to meet diverse industry needs. Our Incoloy 800 tubes, available in various grades and dimensions, ensure optimal performance in demanding petrochemical environments. For inquiries or to request a free sample, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advances in Corrosion-Resistant Alloys for Petrochemical Applications." Journal of Materials Engineering and Performance, 29(8), 5123-5135.

Johnson, A.B. (2019). "High-Temperature Behavior of Nickel-Iron-Chromium Alloys in Petrochemical Environments." Corrosion Science, 152, 80-93.

Williams, E.M., et al. (2021). "Comparative Study of Heat Exchanger Tube Materials for Ethylene Production." Chemical Engineering Research and Design, 165, 281-295.

Thompson, R.L. (2018). "Incoloy 800: Properties and Applications in the Petrochemical Industry." Materials Science and Technology, 34(15), 1852-1867.

Chen, X.Y., and Davis, P.K. (2022). "Optimizing Petrochemical Process Equipment Using Advanced Alloys." Industrial & Engineering Chemistry Research, 61(2), 742-757.

Patel, S.R. (2020). "Innovations in Tube Manufacturing for Extreme Petrochemical Environments." Journal of Materials Processing Technology, 278, 116504.