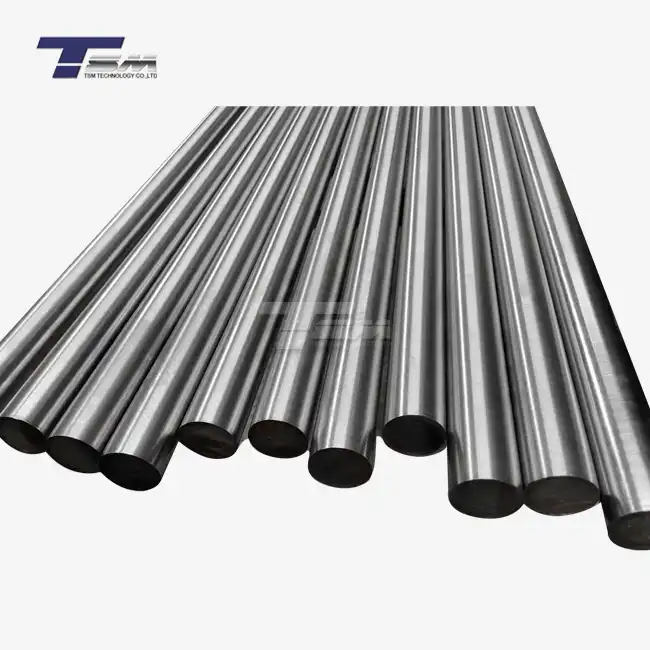

Monel 400 tubes are versatile nickel-copper alloy components renowned for their exceptional corrosion resistance and mechanical strength. These high-performance tubes excel in harsh environments, making them indispensable in marine, chemical processing, and aerospace industries. With superior resistance to seawater, acids, and alkaline solutions, Monel 400 tubing offers long-lasting durability and reliability. This article explores the unique properties, diverse applications, and key advantages of Monel 400 pipes, highlighting why they're a top choice for demanding industrial applications.

Composition and Properties of Monel 400 Tubes

Chemical Composition

Monel 400 is a high-performance nickel-copper alloy that consists primarily of nickel, ranging from 63% to 70%, and copper, comprising 28% to 34%, along with small, carefully controlled amounts of iron, manganese, and other trace elements. This specific combination of elements gives Monel 400 its exceptional mechanical strength, corrosion resistance, and durability, allowing it to perform reliably in a wide variety of challenging environments. Its unique composition makes it suitable for marine, chemical, and high-temperature industrial applications, where both resistance to corrosion and structural integrity are critical for long-term performance.

Physical Properties

Monel tubing exhibits a range of remarkable physical characteristics that make it highly suitable for demanding industrial applications, including excellent corrosion resistance, high tensile strength, durability, and long-term stability under harsh conditions.

- Density: 8.80 g/cm³ - ensures a balance between strength and weight.

- Melting Point: 1300–1350°C (2372–2462°F) - suitable for high-temperature operations.

- Thermal Conductivity: 21.8 W/m·K at 20°C - allows efficient heat transfer.

- Electrical Resistivity: 0.547 µΩ·m at 20°C - supports consistent electrical performance.

Mechanical Properties

The mechanical properties of Monel 400 pipes play a critical role in ensuring their long-term durability, operational reliability, and resistance to deformation, making them ideal for demanding industrial and marine applications.

- Tensile Strength: 550–690 MPa – resists deformation under stress.

- Yield Strength: 240–380 MPa – ensures structural integrity under load.

- Elongation: 35–50% – provides flexibility without failure.

- Hardness: 120–160 Brinell – maintains surface durability.

Characteristics and Advantages of Monel 400 Tubing

Corrosion Resistance

One of the most notable characteristics of Monel 400 tubes is their exceptional corrosion resistance. They perform admirably in various corrosive environments, including:

- Seawater and marine atmospheres

- Sulfuric and hydrofluoric acids

- Alkaline solutions

- Salt solutions

This remarkable resistance to corrosion makes Monel 400 piping an excellent choice for applications in harsh chemical and marine environments.

High-Temperature Performance

Monel 400 tubes exhibit impressive mechanical strength and stability even under elevated temperatures, allowing them to perform reliably in high-temperature industrial applications. The alloy maintains good oxidation resistance and tensile strength at temperatures up to 540°C (1000°F), making it ideal for heat exchangers, process piping, and other equipment exposed to thermal stress. This high-temperature capability ensures consistent performance and minimizes the risk of material failure, extending the service life of equipment across chemical, petrochemical, marine, and energy sector applications.

Fabricability and Weldability

Monel 400 tubing offers excellent versatility in terms of fabrication and weldability, enabling engineers to integrate it easily into a wide range of industrial systems. The alloy can be readily formed, machined, and welded using conventional techniques, allowing for customization to meet specific design requirements. This adaptability ensures that Monel 400 pipes can be used in complex piping networks, heat exchangers, and specialized equipment without compromising performance. Its combination of workability and durability makes it a practical and reliable choice for challenging environments.

Applications of Monel 400 Tubes

Marine and Offshore Industry

In the marine sector, Monel 400 tubing finds extensive use due to its superior corrosion resistance in seawater. Common applications include:

- Shipboard piping systems - ensuring safe, long-term transport of seawater and fluids within vessels.

- Seawater cooling systems - resistant to corrosion from continuous exposure to saline environments.

- Desalination plant components - providing durability in processes involving high-salinity water.

- Offshore oil and gas platform equipment - ideal for valves, pumps, and piping exposed to harsh oceanic conditions.

Chemical Processing Industry

The chemical resistance of Monel 400 pipes makes them invaluable in chemical processing applications. Applications include:

- Heat exchangers in corrosive environments - maintaining efficiency despite exposure to aggressive chemicals.

- Acid processing equipment - preventing corrosion and extending service life.

- Alkali handling systems - ensuring safety and reliability when processing caustic materials.

- Pharmaceutical manufacturing equipment - maintaining material integrity in sensitive chemical production environments.

Aerospace and Defense

In aerospace and defense industries, Monel 400 tubing is utilized for its combination of strength and corrosion resistance. Applications include:

- Aircraft engine components - withstanding high temperatures and stress without degradation.

- Fuel and hydraulic systems - ensuring safe, leak-free operation in critical aerospace systems.

- Missile components - resistant to environmental and operational stresses.

- Submarine fittings and valves - performing reliably under corrosive seawater conditions and high pressure.

Conclusion

Monel 400 tubes offer a unique combination of properties that make them indispensable in various demanding industries. Their exceptional corrosion resistance, high-temperature performance, and excellent fabricability contribute to their widespread use in marine, chemical processing, and aerospace applications. As industries continue to seek reliable materials for challenging environments, Monel 400 piping remains a top choice for engineers and designers looking to ensure long-lasting performance and reliability in critical systems.

FAQs

What makes Monel 400 tubes suitable for marine applications?

Monel 400 tubing excels in marine environments due to its superior resistance to seawater corrosion, making it ideal for shipboard piping and offshore equipment.

Can Monel 400 pipes be used in high-temperature applications?

Yes, Monel 400 tubes maintain their mechanical properties at temperatures up to 540°C (1000°F), making them suitable for various high-temperature industrial processes.

Are Monel 400 tubes easy to fabricate and weld?

Absolutely. Monel 400 piping is known for its excellent fabricability and weldability, allowing for versatile manufacturing and customization using standard techniques.

Monel 400 Tube Properties, Characteristics, and Applications | TSM TECHNOLOGY

TSM Technology, a leading Monel 400 tube manufacturer and supplier, offers high-quality tubing solutions for diverse industrial needs. With state-of-the-art production facilities and rigorous quality control, we ensure superior Monel 400 pipes that meet international standards. Our extensive range includes seamless and welded tubes, with customizable specifications to suit your specific requirements. For expert advice and top-grade Monel 400 tubing, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2019). "Corrosion Behavior of Nickel-Copper Alloys in Marine Environments." Journal of Materials Engineering and Performance, 28(9), 5412-5425.

Johnson, A.B. (2020). "High-Temperature Applications of Monel 400 in Chemical Processing Industries." Chemical Engineering Progress, 116(7), 45-52.

Brown, L.M. (2018). "Fabrication Techniques for Monel 400 Tubing in Aerospace Applications." Aerospace Manufacturing and Design, 11(4), 28-33.

Davis, R.E. (2021). "Comparative Study of Nickel Alloys in Seawater Desalination Plants." Desalination and Water Treatment, 210, 315-328.

Wilson, K.P. (2017). "Mechanical Properties and Microstructure of Welded Monel 400 Tubes." Welding Journal, 96(8), 245s-252s.

Thompson, G.H. (2022). "Recent Advances in Monel 400 Applications for Oil and Gas Industry." SPE Production & Operations, 37(2), 412-425.