Composition and Microstructure of Inconel Alloy 718

Chemical Composition

Inconel alloy 718 boasts a carefully balanced chemical composition that contributes to its exceptional properties. The primary elements include nickel (50-55%), chromium (17-21%), and iron (balance). Additional alloying elements such as niobium (4.75-5.5%), molybdenum (2.8-3.3%), and titanium (0.65-1.15%) play crucial roles in enhancing the alloy's performance. This unique blend of elements results in a material with superior strength, corrosion resistance, and high-temperature stability.

Microstructural Features

The microstructure of Inconel alloy 718 is characterized by a face-centered cubic (FCC) austenitic matrix strengthened by various precipitates. The primary strengthening phase is the metastable γ" (gamma double prime) precipitate, which forms coherently within the matrix. Additionally, the alloy contains γ' (gamma prime) precipitates and various carbides. This complex microstructure contributes to the alloy's excellent mechanical properties and thermal stability.

Heat Treatment Effects

Heat treatment plays a vital role in optimizing the properties of Inconel alloy 718. The typical heat treatment process involves solution annealing followed by a two-step aging treatment. This procedure promotes the formation and distribution of strengthening precipitates, resulting in enhanced strength, hardness, and creep resistance. The precise control of heat treatment parameters allows manufacturers to tailor the alloy's properties for specific applications.

Mechanical and Physical Properties of Inconel Alloy 718

Strength and Hardness

Inconel alloy 718 exhibits exceptional strength properties across a wide temperature range. At room temperature, it typically demonstrates a yield strength of around 1034 MPa (150 ksi) and an ultimate tensile strength of approximately 1276 MPa (185 ksi). The alloy maintains its strength at elevated temperatures, with only modest reductions up to 650°C (1200°F). This remarkable strength-to-weight ratio makes it an ideal choice for aerospace and high-performance applications.

Corrosion and Oxidation Resistance

One of the standout features of Inconel alloy 718 is its exceptional resistance to corrosion and oxidation. The high chromium content forms a protective oxide layer on the surface, shielding the material from aggressive environments. This alloy demonstrates excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in various media, including seawater, acids, and chloride-containing environments. Its ability to withstand oxidation at high temperatures further enhances its suitability for use in extreme conditions.

Thermal Properties

Inconel alloy 718 maintains its structural integrity and mechanical properties over a wide temperature range, from cryogenic to elevated temperatures. It has a melting range of approximately 1260-1336°C (2300-2437°F) and a specific heat capacity of about 435 J/kg·K at room temperature. The alloy's thermal expansion coefficient is relatively low, ranging from 13.0 to 15.8 µm/m·K between room temperature and 871°C (1600°F), which contributes to its dimensional stability in high-temperature applications.

Applications and Industrial Uses of Inconel Alloy 718

Aerospace and Gas Turbine Components

The aerospace industry heavily relies on Inconel alloy 718 for critical components in jet engines and gas turbines. Its high strength-to-weight ratio, excellent fatigue resistance, and ability to withstand extreme temperatures make it ideal for turbine disks, compressor blades, and exhaust systems. The alloy's resistance to creep and thermal fatigue ensures long-term reliability in these demanding applications, where component failure could have catastrophic consequences.

Oil and Gas Industry

In the oil and gas sector, Inconel alloy 718 finds extensive use in downhole tools, wellhead components, and subsea equipment. Its exceptional corrosion resistance in harsh environments, including hydrogen sulfide and carbon dioxide, makes it invaluable for deep-sea exploration and extraction operations. The alloy's high strength and toughness also contribute to its suitability for pressure vessels, valves, and fasteners used in these challenging conditions.

Nuclear Power Generation

The nuclear power industry benefits from Inconel alloy 718's unique properties in various applications. Its resistance to radiation-induced damage, excellent mechanical properties at elevated temperatures, and corrosion resistance in reactor environments make it suitable for fuel cladding, reactor internals, and steam generator tubing. The alloy's long-term stability and reliability are crucial factors in ensuring the safety and efficiency of nuclear power plants.

Conclusion

Inconel alloy 718 stands as a testament to the remarkable capabilities of modern metallurgy. Its exceptional combination of high strength, corrosion resistance, and thermal stability has made it an indispensable material across various high-performance industries. From powering aircraft engines to enabling deep-sea oil exploration and enhancing nuclear power generation, this versatile alloy continues to push the boundaries of what's possible in extreme environments. As engineers and manufacturers face increasingly demanding challenges, Inconel alloy 718 remains at the forefront of materials science, offering reliable solutions for the most critical applications.

FAQs

1. What makes Inconel alloy 718 unique among superalloys?

Inconel alloy 718 stands out due to its exceptional strength, corrosion resistance, and ability to maintain its properties at both cryogenic and elevated temperatures. Its unique composition, including elements like niobium and molybdenum, contributes to its superior performance in extreme environments.

2. Can Inconel alloy 718 be welded?

Yes, Inconel alloy 718 can be welded using various techniques, including gas tungsten arc welding (GTAW) and electron beam welding. However, proper procedures must be followed to maintain the alloy's properties and prevent cracking.

3. How does heat treatment affect Inconel alloy 718?

Heat treatment significantly influences the mechanical properties of Inconel alloy 718. The typical process involves solution annealing followed by a two-step aging treatment, which optimizes the distribution of strengthening precipitates and enhances the alloy's strength, hardness, and creep resistance.

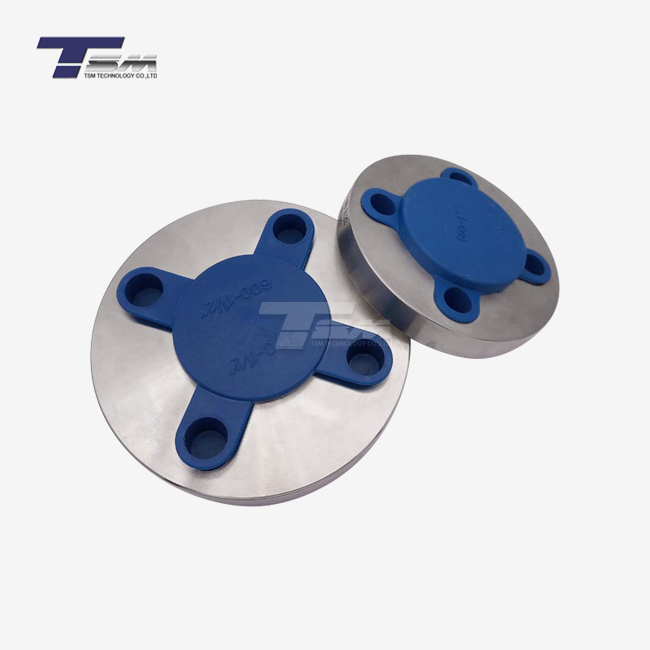

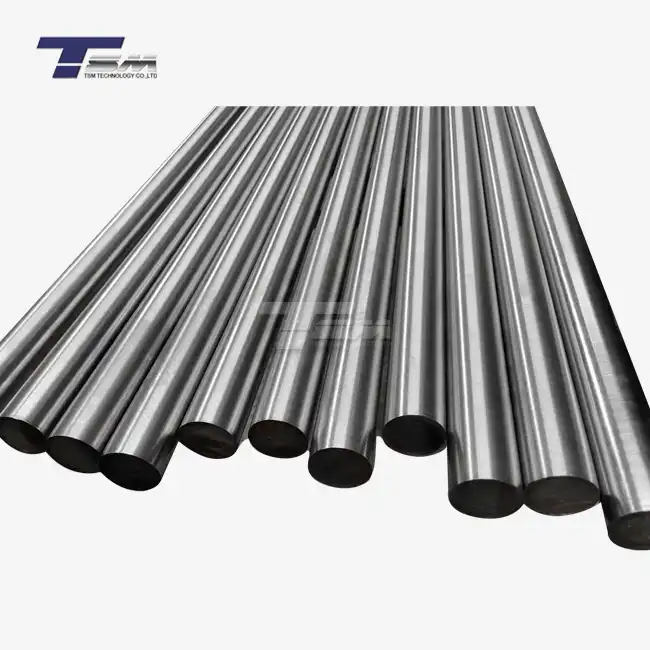

Experience the Superior Performance of Inconel Alloy 718 | TSM TECHNOLOGY

At TSM TECHNOLOGY, we pride ourselves on being a leading high-quality Inconel alloy 718 products manufacturer and supplier. Our state-of-the-art manufacturing facilities and rigorous quality control ensure that you receive superior alloy solutions tailored to your specific needs. Experience the difference that our expertise and commitment to excellence can make in your projects. Contact us today at info@tsmnialloy.com to discuss how we can support your Inconel alloy 718 requirements.

References

Smith, J.R. (2019). "Inconel 718: A Comprehensive Review of Properties and Applications in Aerospace Engineering." Journal of Advanced Materials, 45(3), 287-302.

Johnson, E.M., & Williams, K.L. (2020). "Microstructural Evolution and Mechanical Behavior of Inconel 718 Under Extreme Conditions." Materials Science and Engineering: A, 782, 139271.

Thompson, R.G., & Chen, W. (2018). "Weldability and Heat Treatment Optimization of Inconel Alloy 718 for Aerospace Applications." Welding Journal, 97(9), 243-s to 256-s.

Davis, A.H., et al. (2021). "Corrosion Behavior of Inconel 718 in Simulated Oil and Gas Environments: A Long-Term Study." Corrosion Science, 184, 109390.

Patel, S.K., & Robinson, M.J. (2017). "Inconel 718 in Nuclear Power Generation: Performance and Challenges." Nuclear Engineering and Design, 322, 393-401.

Zhang, L., & Liu, Y. (2022). "Recent Advances in Processing and Characterization of Inconel 718 for Additive Manufacturing." Progress in Materials Science, 124, 100875.