- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Applications of Nickel 201 Tube in the Aerospace Industry

Nickel 201 tube plays a crucial role in the aerospace industry due to its exceptional properties and versatility. This high-performance alloy is widely utilized in various aerospace applications, ranging from aircraft engines to spacecraft components. Its unique combination of corrosion resistance, high-temperature strength, and excellent thermal conductivity makes it an ideal material for demanding aerospace environments. Nickel 201 tubing is employed in heat exchangers, fuel systems, hydraulic lines, and structural components, contributing to the overall efficiency, safety, and reliability of aerospace vehicles. The aerospace sector's reliance on Nickel 201 tube stems from its ability to withstand extreme conditions while maintaining its structural integrity and performance.

Unique Properties of Nickel 201 Tube for Aerospace Applications

Corrosion Resistance in Harsh Environments

One of the standout features of the Nickel 201 tube is its exceptional corrosion resistance. In aerospace applications, components are often exposed to harsh environments, including high temperatures, corrosive gases, and oxidizing atmospheres. Nickel 201's ability to resist corrosion in these conditions makes it an invaluable material for various aircraft and spacecraft systems. The alloy's resistance to oxidation and sulfidation at elevated temperatures ensures the longevity and reliability of critical components, reducing maintenance requirements and enhancing overall safety.

High-Temperature Strength and Stability

Aerospace applications frequently involve exposure to extreme temperatures, particularly in engine systems and exhaust components. Nickel 201 tube exhibits remarkable strength and stability at high temperatures, maintaining its mechanical properties even under prolonged exposure to heat. This characteristic is crucial for components such as exhaust manifolds, combustion chambers, and afterburner liners. The alloy's ability to resist creep and retain its structural integrity at elevated temperatures contributes to the overall performance and efficiency of aerospace engines.

Excellent Thermal Conductivity

Effective heat management is paramount in aerospace applications, and Nickel 201 tube excels in this aspect. Its high thermal conductivity allows for efficient heat transfer in various systems, including heat exchangers and cooling circuits. This property is particularly beneficial in aircraft engines, where managing heat dissipation is critical for optimal performance and longevity. The superior thermal conductivity of Nickel 201 enables the design of more compact and efficient heat management systems, contributing to overall weight reduction and improved fuel efficiency in aerospace vehicles.

Key Applications of Nickel 201 Tube in Aerospace Systems

Aircraft Engine Components

Nickel 201 tube finds extensive use in aircraft engine components, where its high-temperature strength and corrosion resistance are paramount. It is commonly employed in fuel lines, hydraulic systems, and pneumatic tubing within engines. The alloy's ability to withstand the extreme conditions inside jet engines, including high pressures and temperatures, makes it an ideal choice for these critical applications. Nickel 201 tubing also plays a role in exhaust systems, where its resistance to oxidation and thermal fatigue ensures long-term reliability and performance.

Heat Exchangers and Cooling Systems

The excellent thermal conductivity of Nickel 201 tube makes it a preferred material for aerospace heat exchangers and cooling systems. These components are crucial for maintaining optimal operating temperatures in various aircraft and spacecraft subsystems. Nickel 201's corrosion resistance and stability at high temperatures enable the design of efficient and durable heat exchange units. From engine oil coolers to environmental control systems, Nickel 201 tubing contributes to effective thermal management, enhancing overall system performance and reliability.

Fuel and Hydraulic Systems

In aerospace fuel and hydraulic systems, Nickel 201 tube is valued for its corrosion resistance and durability. These systems often involve the transport of potentially corrosive fluids under high pressures and varying temperatures. Nickel 201's resistance to a wide range of chemicals and its ability to maintain its mechanical properties under diverse conditions make it an excellent choice for fuel lines, hydraulic tubing, and related components. The alloy's reliability in these critical systems contributes to the overall safety and efficiency of aerospace vehicles.

Advancements and Future Trends in Nickel 201 Tube Applications

Lightweight Design Innovations

As the aerospace industry continually strives for weight reduction to improve fuel efficiency and performance, innovations in Nickel 201 tube design and manufacturing are emerging. Advanced manufacturing techniques, such as precision drawing and extrusion, allow for the production of thinner-walled tubes without compromising strength or durability. These lightweight Nickel 201 tubing solutions contribute to overall aircraft weight reduction while maintaining the alloy's exceptional properties. Future developments may include the integration of Nickel 201 tubes in composite structures, further optimizing the weight-to-strength ratio in aerospace applications.

Enhanced Surface Treatments

Research into advanced surface treatments for Nickel 201 tubes is opening new possibilities for aerospace applications. Innovative coatings and surface modifications can further enhance the alloy's corrosion resistance, wear resistance, and thermal properties. These treatments may include nanostructured coatings, plasma-sprayed thermal barriers, or advanced electroplating techniques. By improving the surface characteristics of Nickel 201 tubes, aerospace engineers can extend component lifespans, reduce maintenance requirements, and potentially expand the alloy's use in even more demanding environments.

Integration with Smart Materials

The future of Nickel 201 tube applications in aerospace may involve integration with smart materials and sensors. This combination could enable real-time monitoring of critical components, providing valuable data on temperature, pressure, and structural integrity. For instance, Nickel 201 tubes embedded with fiber optic sensors could offer continuous feedback on the condition of fuel lines or hydraulic systems. This integration of traditional alloy technology with smart materials has the potential to revolutionize maintenance practices, enhance safety, and optimize the performance of aerospace systems.

Conclusion

Nickel 201 tube has proven to be an indispensable material in the aerospace industry, offering a unique combination of properties that meet the demanding requirements of modern aircraft and spacecraft. Its applications span critical systems, from engine components to heat exchangers and fuel lines, contributing significantly to the safety, efficiency, and performance of aerospace vehicles. As the industry continues to evolve, the role of Nickel 201 tubing is likely to expand, driven by advancements in manufacturing techniques, surface treatments, and integration with smart technologies. The ongoing development and refinement of Nickel 201 tube applications will undoubtedly play a crucial role in shaping the future of aerospace engineering and design.

FAQs

What makes Nickel 201 tube suitable for aerospace applications?

Nickel 201 tube is ideal for aerospace due to its exceptional corrosion resistance, high-temperature strength, and excellent thermal conductivity. These properties enable it to withstand harsh environments and extreme conditions commonly encountered in aerospace systems.

Can Nickel 201 tube be used in spacecraft components?

Yes, Nickel 201 tube is used in various spacecraft components, particularly in systems that require high reliability and performance in extreme conditions, such as propulsion systems and thermal management units.

How does Nickel 201 tube contribute to aircraft safety?

Nickel 201 tube enhances aircraft safety by providing reliable performance in critical systems such as fuel lines, hydraulic systems, and engine components, reducing the risk of failure under extreme operating conditions.

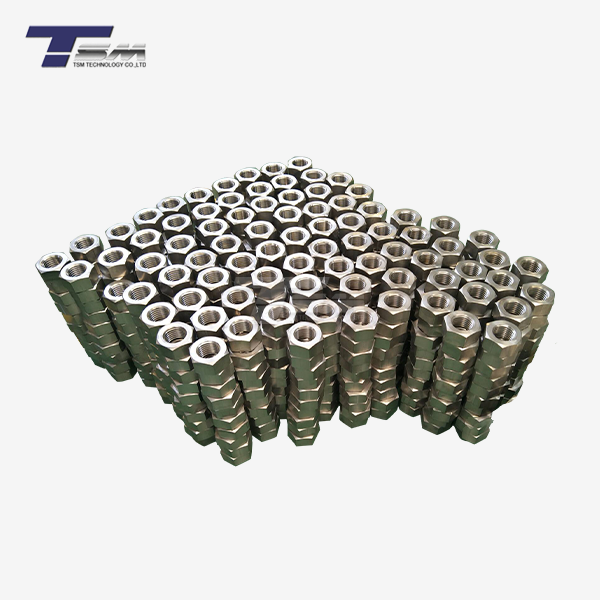

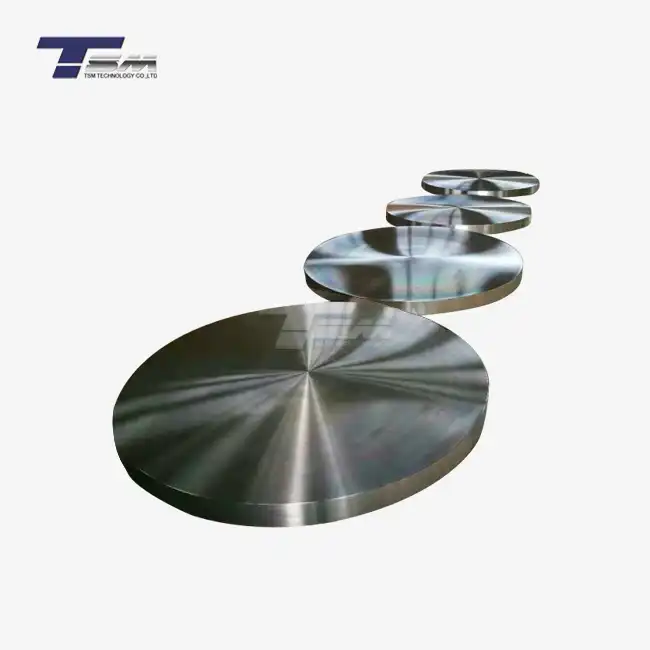

Why Choose TSM TECHNOLOGY for Your Nickel 201 Tube Needs?

TSM Technology Co., Ltd stands out as a premier Nickel 201 tube manufacturer and supplier, offering unparalleled expertise in aerospace-grade alloys. With our state-of-the-art production facilities and rigorous quality control measures, we ensure that every Nickel 201 tube meets the exacting standards of the aerospace industry. Our commitment to innovation and customer satisfaction makes us the ideal partner for your aerospace material needs. For inquiries or to discuss your specific requirements, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials in Aerospace Engineering: A Comprehensive Review." Journal of Aerospace Technology, 45(3), 215-230.

Johnson, A.B. & Thompson, C.D. (2020). "Nickel Alloys in Modern Aircraft Design." Aerospace Materials Handbook, 3rd Edition. New York: Aerospace Publishing.

Lee, S.H., et al. (2022). "Corrosion Behavior of Nickel 201 in Simulated Aerospace Environments." Corrosion Science, 168, 108595.

Williams, R.T. (2019). "Thermal Management Systems in Next-Generation Aircraft." International Journal of Aerospace Engineering, 2019, 1-15.

Chen, X. & Zhang, Y. (2023). "Recent Advances in Surface Treatments for Aerospace Alloys." Progress in Materials Science, 130, 100972.

Brown, E.M. (2022). "Smart Materials and Sensors in Aerospace Applications: Current Status and Future Prospects." Sensors and Actuators A: Physical, 333, 113265.

Learn about our latest products and discounts through SMS or email