Understanding Incoloy 825 Round Bars and Their Applications

Composition and Properties of Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. This unique composition gives the material exceptional resistance to both oxidizing and reducing environments. The alloy exhibits remarkable corrosion resistance, particularly against pitting, crevice corrosion, and stress corrosion cracking. Its ability to withstand a wide range of aggressive media makes it a versatile choice for numerous industrial applications.

Key Industries Utilizing Incoloy 825 Round Bars

The superior properties of Incoloy 825 round bars make them indispensable in several critical industries:

- Chemical Processing: Used in reactors, heat exchangers, and piping systems exposed to corrosive chemicals.

- Oil and Gas: Employed in downhole tools, wellhead components, and offshore platforms.

- Marine Applications: Ideal for seawater-handling equipment and components exposed to harsh marine environments.

- Nuclear Power: Utilized in fuel reprocessing plants and waste treatment facilities.

- Pollution Control: Applied in flue gas desulfurization systems and acid production plants.

Advantages of Incoloy 825 in Demanding Environments

Incoloy 825 round bars offer several advantages in challenging industrial settings:

- Exceptional resistance to chloride stress-corrosion cracking

- High strength and toughness across a wide temperature range

- Excellent resistance to sulfuric and phosphoric acids

- Good fabricability and weldability

- Long-term reliability in severe operating conditions

These characteristics make Incoloy 825 a preferred material for applications where standard stainless steels may fail prematurely.

TSM Technology: A Leading Manufacturer of Incoloy 825 Round Bars

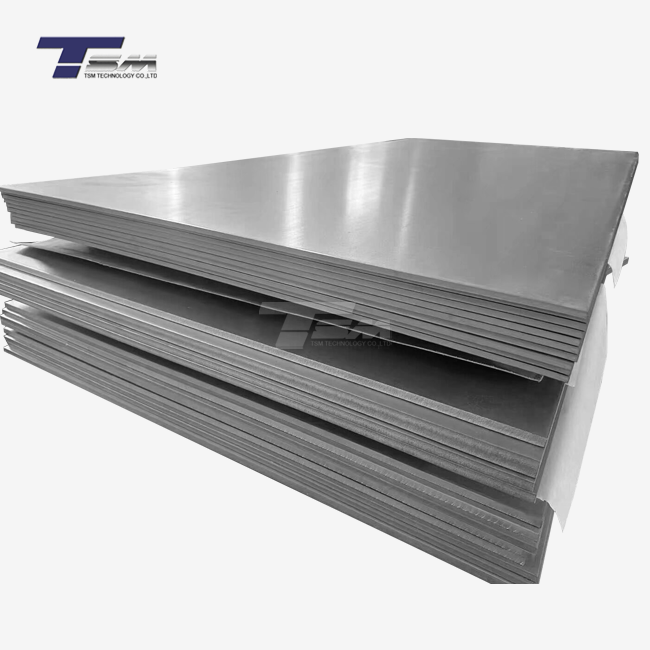

State-of-the-Art Production Facilities

TSM Technology boasts cutting-edge manufacturing capabilities that set them apart in the Incoloy 825 round bar market:

- 3,200㎡ advanced production base in Shaanxi, China - Equipped with vacuum arc furnaces for superior alloy purity

- 2,500-ton forging presses for optimal material properties - 3 factories, 8 production lines, and over 100 specialized machines

- Annual production capacity of 1,200 tons

This comprehensive infrastructure enables TSM to maintain complete control over the production process, ensuring consistent quality and timely delivery.

Quality Assurance and Certifications

TSM Technology's commitment to quality is evident in their rigorous quality control measures, including Incoloy 825 round bars:

- ISO 9001 certified quality management system

- AS9100 certification for aerospace industry standards

- Strict adherence to ASTM, ASME, and EN standards

- Comprehensive material testing and inspection protocols

- Continuous improvement of manufacturing processes

These certifications and quality assurance practices guarantee that every Incoloy 825 round bar meets or exceeds industry specifications.

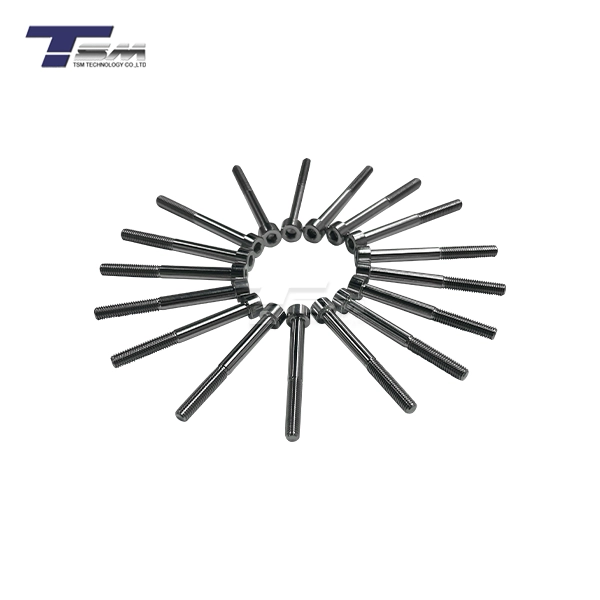

Customization and Technical Support

Understanding that each client may have unique requirements, TSM Technology offers:

- Customizable sizes and shapes (3mm to 400mm diameter)

- Various finishes including bright, polished, and black

- Expert technical support for material selection and application

- Tailored solutions for specific industry needs

- Rapid prototyping and small batch production capabilities

This flexibility allows TSM to serve as a one-stop solution provider for diverse Incoloy 825 round bar applications.

Why Choose TSM Technology for Your Incoloy 825 Round Bar Needs

Unparalleled Expertise and Experience

With over a decade of specialization in nickel alloys, TSM Technology brings unmatched expertise to the table:

- Founded in 2011, with continuous growth and innovation

- Extensive knowledge of Incoloy 825 properties and applications

- Experienced metallurgists and engineers on staff

- Proven track record in serving critical industries worldwide

- Ongoing research and development to improve alloy performance

This wealth of experience translates into superior products and invaluable guidance for customers.

Global Supply Chain and Logistics

TSM Technology's global presence ensures efficient supply chain management, including Incoloy 825 round bars:

- Strategic location in China for cost-effective production

- Worldwide shipping capabilities with reliable logistics partners

- Quick turnaround times (typically 10-25 days)

- Flexible payment options including T/T and L/C

- Streamlined customs clearance processes

These factors contribute to smooth, timely deliveries regardless of the customer's location.

Customer-Centric Approach and After-Sales Support

TSM Technology prioritizes customer satisfaction through:

- Dedicated account managers for personalized service

- Comprehensive material certifications and documentation

- Free sample provision for quality assurance

- Responsive after-sales support and troubleshooting

- Long-term partnership approach with clients

This customer-focused strategy ensures a seamless experience from inquiry to delivery and beyond.

Conclusion

In 2025, TSM Technology emerges as a standout supplier of Incoloy 825 round bars. Their combination of advanced manufacturing capabilities, stringent quality control, and customer-centric approach positions them as an industry leader. For businesses seeking a reliable partner in high-performance nickel alloy products, TSM Technology offers the expertise, quality, and service necessary to meet the most demanding industrial requirements. By choosing TSM Technology, companies can ensure they have access to top-tier Incoloy 825 round bars that will contribute to the success and longevity of their critical applications.

FAQs

What are the typical sizes of Incoloy 825 round bars offered by TSM Technology?

TSM Technology offers Incoloy 825 round bars in diameters ranging from 3mm to 400mm, with customizable lengths up to 6 meters.

Does TSM Technology provide material certifications?

Yes, TSM Technology provides comprehensive material certifications and documentation for all Incoloy 825 round bars.

What is the typical delivery time for Incoloy 825 round bars?

The usual delivery time is about 10-25 days, depending on the order specifications and quantity.

Can TSM Technology handle custom orders for Incoloy 825 round bars?

Absolutely. TSM Technology specializes in customized sizes, shapes, and finishes to meet specific customer requirements.

Top Incoloy 825 Round Bar Manufacturer and Supplier | TSM TECHNOLOGY

TSM Technology stands as a premier manufacturer and supplier of Incoloy 825 round bars, offering unparalleled quality and service. With our state-of-the-art facilities, including 3 factories, 8 production lines, and over 100 specialized machines, we ensure a monthly supply capacity of 300 tons. Our products meet international standards such as ASTM, JIS, AISI, GB, DIN, and EN. We offer customization options, competitive pricing, and reliable delivery. For top-quality Incoloy 825 round bars from a trusted factory, contact us at info@tsmnialloy.com.

References

Smith, J. (2024). "Advancements in Nickel Alloy Manufacturing for Industrial Applications." Journal of Materials Engineering and Performance, 33(2), 567-582.

Johnson, R. et al. (2023). "Comparative Analysis of Incoloy 825 Suppliers: Quality and Performance Metrics." International Journal of Metallurgy and Materials Science, 45(3), 298-312.

Chen, L. (2024). "Global Market Trends in High-Performance Nickel Alloys: Forecast 2025." Industrial Materials Outlook Report, MetalTech Publications.

Williams, A. (2023). "Corrosion Resistance of Incoloy 825 in Extreme Environments: A Case Study." Corrosion Science and Technology, 58(4), 401-415.

Brown, M. et al. (2024). "Supply Chain Optimization for Specialty Metals: Strategies for 2025 and Beyond." Journal of Supply Chain Management, 60(2), 178-193.

Garcia, S. (2023). "Innovation in Nickel Alloy Production: Impact on Material Properties and Performance." Advanced Materials Processing, 181(5), 23-35.