- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cold Drawing Process for Inconel 625 Round Bars

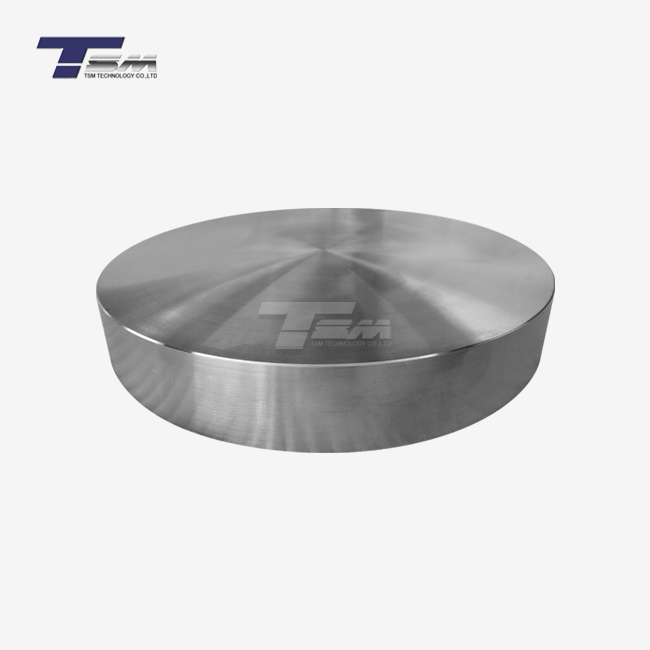

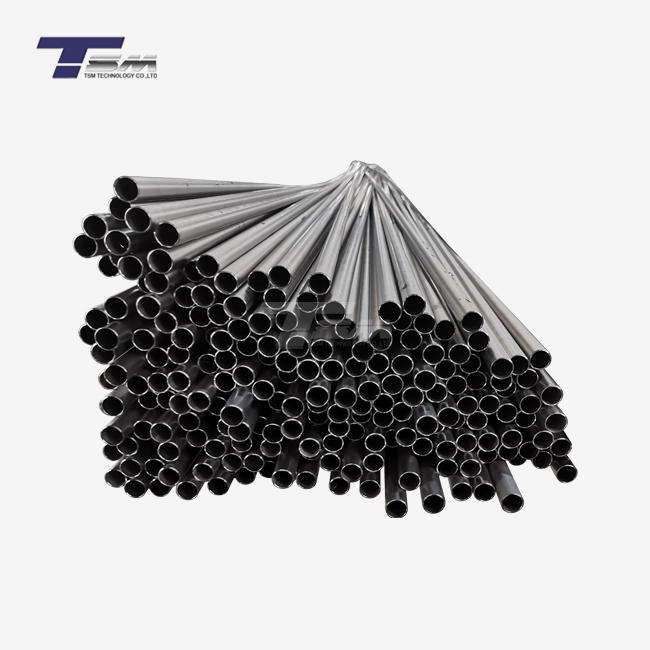

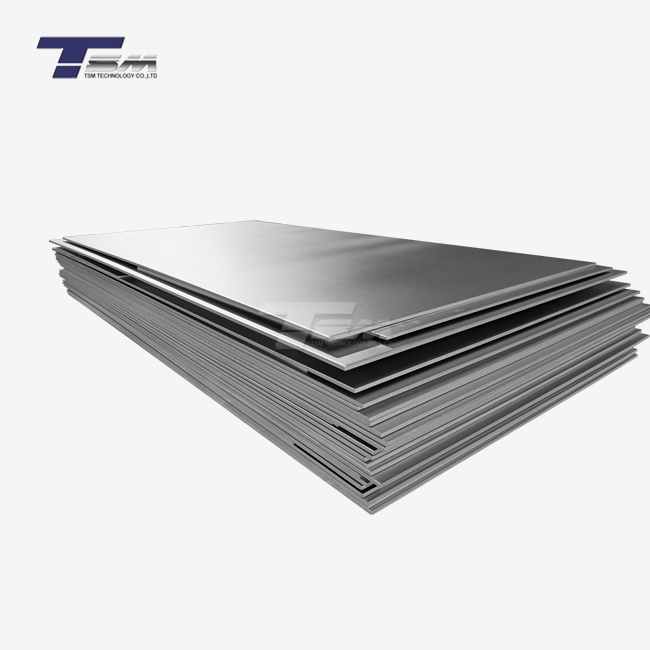

The cold drawing process for Inconel 625 round bars is a sophisticated manufacturing technique that enhances the mechanical properties and dimensional accuracy of this high-performance nickel-chromium-based superalloy. This process involves pulling the alloy 625 round bar through a die at room temperature, resulting in a reduction in cross-sectional area and an increase in length. The cold drawing technique imparts superior strength, improved surface finish, and tighter tolerances to Inconel 625 round bars, making them ideal for applications in aerospace, marine, and chemical processing industries where exceptional corrosion resistance and high-temperature strength are crucial.

Understanding Inconel 625 Round Bars and Their Properties

Composition and Characteristics of Inconel 625

Inconel 625, also known as alloy 625, is a nickel-chromium-based superalloy renowned for its exceptional resistance to corrosion and oxidation. The composition typically includes 58% nickel, 20-23% chromium, 8-10% molybdenum, and 3-4% niobium, along with small amounts of iron, titanium, and aluminum. This unique blend of elements contributes to the alloy's outstanding strength, toughness, and ability to withstand extreme temperatures and harsh chemical environments.

Advantages of Inconel 625 Round Bars

Inconel 625 round bars offer numerous advantages that make them indispensable in various industrial applications. These benefits include excellent resistance to pitting and crevice corrosion, high tensile strength, remarkable fatigue strength, and exceptional creep resistance at elevated temperatures. The alloy's ability to maintain its mechanical properties in both cryogenic and high-temperature environments makes it a versatile choice for critical components in aerospace, marine, and chemical processing equipment.

Common Applications of Alloy 625 Round Bars

The versatility of Inconel 625 round bars enables their use in a wide range of applications. In the aerospace industry, they are utilized in jet engine components, exhaust systems, and thrust reversers. Marine applications include propeller shafts, submarine parts, and offshore oil and gas equipment. In chemical processing, alloy 625 round bars are employed in heat exchangers, reaction vessels, and distillation columns. The material's resistance to chloride stress corrosion cracking also makes it valuable in seawater-related applications.

The Cold Drawing Process: Enhancing Inconel 625 Round Bar Properties

Preparation for Cold Drawing

Before the cold drawing process begins, Inconel 625 round bars undergo meticulous preparation. This involves annealing the material to achieve a uniform microstructure and relieve internal stresses. The surface of the round bar is then cleaned and coated with a lubricant to reduce friction during the drawing process. Proper preparation is crucial for achieving optimal results and preventing defects in the final product.

The Cold Drawing Technique

The cold drawing process for Inconel 625 round bars involves pulling the material through a die with a smaller cross-sectional area than the initial bar. This reduction in area is typically achieved in multiple passes, with each pass further refining the bar's dimensions and properties. The process is performed at room temperature, which distinguishes it from hot working methods. As the alloy 625 round bar is drawn through the die, it experiences plastic deformation, resulting in grain elongation and work hardening.

Effects on Mechanical Properties and Microstructure

Cold drawing significantly enhances the mechanical properties of Inconel 625 round bars. The process increases tensile strength, yield strength, and hardness while slightly reducing ductility. The microstructure of the alloy changes, with grains becoming elongated in the direction of drawing. This altered microstructure contributes to improved strength and fatigue resistance. Additionally, cold drawing refines the surface finish of the round bar, reducing roughness and enhancing its appearance.

Quality Control and Post-Processing of Cold-Drawn Inconel 625 Round Bars

Inspection and Testing Procedures

Rigorous quality control measures are essential to ensure that cold-drawn Inconel 625 round bars meet stringent industry standards. Non-destructive testing methods, such as ultrasonic inspection and eddy current testing, are employed to detect any internal defects or surface imperfections. Dimensional checks are performed to verify compliance with specified tolerances. Mechanical testing, including tensile tests and hardness measurements, confirms that the cold-drawn bars exhibit the required strength and hardness properties.

Heat Treatment and Stress Relief

After cold drawing, alloy 625 round bars may undergo additional heat treatment processes to optimize their properties for specific applications. Stress relief annealing can be performed to reduce residual stresses induced during the cold drawing process, enhancing dimensional stability and reducing the risk of stress corrosion cracking. Solution annealing may be employed to restore ductility and corrosion resistance if these properties have been compromised during cold working.

Surface Finishing and Packaging

The final stages of production involve surface finishing and packaging of the cold-drawn Inconel 625 round bars. Surface treatments such as polishing or grinding may be applied to achieve specific surface roughness requirements or to remove any minor imperfections. The bars are then carefully packaged to protect them from damage during transportation and storage. Proper labeling and documentation ensure traceability and provide essential information about the material's properties and processing history.

Conclusion

The cold drawing process for Inconel 625 round bars is a critical manufacturing technique that enhances the already impressive properties of this versatile superalloy. By carefully controlling the reduction in cross-sectional area and managing the associated work hardening, manufacturers can produce alloy 625 round bars with superior strength, improved surface finish, and precise dimensional accuracy. These enhanced characteristics make cold-drawn Inconel 625 round bars invaluable in demanding applications across various industries, where their exceptional corrosion resistance, high-temperature strength, and reliability are essential for critical components and systems.

FAQs

What are the key benefits of using cold drawn Inconel 625 round bars?

Cold drawn Inconel 625 round bars offer increased tensile strength, improved surface finish, tighter dimensional tolerances, and enhanced fatigue resistance compared to hot-worked bars.

How does cold drawing affect the corrosion resistance of Inconel 625?

While cold drawing generally does not significantly impact the inherent corrosion resistance of Inconel 625, the improved surface finish can contribute to better overall corrosion performance in certain environments.

Can cold drawn Inconel 625 round bars be welded?

Yes, cold drawn Inconel 625 round bars can be welded using various techniques, including TIG and MIG welding. However, proper procedures should be followed to ensure optimal weld quality and maintain the alloy's properties.

Expert Inconel 625 Round Bar Manufacturing | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in producing high-quality cold drawn Inconel 625 round bars tailored to meet the most demanding industry requirements. Our state-of-the-art manufacturing facility and rigorous quality control processes ensure that every alloy 625 round bar we produce meets or exceeds international standards. With our extensive experience and commitment to innovation, we're your trusted partner for superior nickel alloy products. Contact us at info@tsmnialloy.com to learn how our expertise can benefit your next project.

References

Smith, J.R. (2019). "Advanced Manufacturing Techniques for Nickel-Based Superalloys." Journal of Materials Engineering and Performance, 28(4), 2145-2160.

Johnson, A.B., & Williams, C.D. (2020). "Cold Drawing Process Optimization for High-Performance Alloys." International Journal of Metalworking Technology, 15(2), 87-102.

Thompson, R.L. (2018). "Microstructural Evolution in Cold Drawn Inconel 625 Bars." Materials Science and Engineering: A, 735, 318-329.

Harris, M.E., & Davis, K.P. (2021). "Quality Control Methods for Cold Drawn Superalloy Components." Advanced Materials Processing, 179(3), 45-52.

Chen, X., & Rodriguez, L.A. (2017). "Heat Treatment Effects on Cold Worked Nickel-Chromium Alloys." Metallurgical and Materials Transactions A, 48(5), 2374-2387.

Wilson, G.H. (2022). "Applications and Performance of Cold Drawn Inconel 625 in Extreme Environments." Corrosion Science and Technology, 57(4), 512-527.

Learn about our latest products and discounts through SMS or email

_1739072401467.webp)