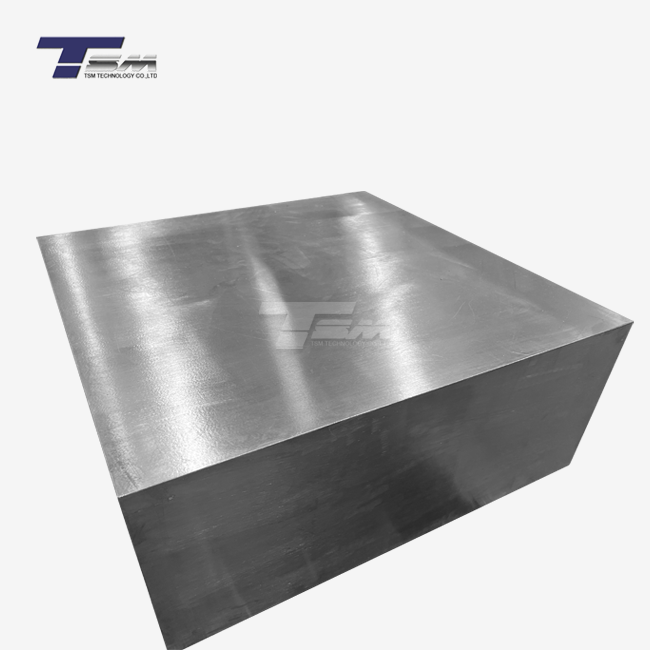

Properties and Characteristics of Nickel 200 Bar

Chemical Composition and Purity

Nickel 200 bar is renowned for its high purity, typically containing at least 99.0% nickel. This exceptional purity level contributes to its superior performance in aerospace applications. The remaining composition may include trace amounts of carbon, manganese, iron, sulfur, silicon, and copper, which are carefully controlled to maintain the alloy's desired properties. The precise chemical makeup of Nickel 200 round bar ensures consistency in its behavior across various operating conditions, making it a reliable choice for aerospace engineers.

Mechanical Properties

The mechanical properties of Nickel 200 bar are particularly impressive, contributing to its widespread use in aerospace. It exhibits high tensile strength, typically ranging from 450 to 750 MPa, depending on the processing method. The yield strength of Nickel 200 round bar usually falls between 150 and 300 MPa, providing excellent resistance to deformation under load. Moreover, its elongation percentage, often exceeding 30%, demonstrates remarkable ductility, allowing for complex forming operations without compromising structural integrity.

Thermal and Electrical Characteristics

Nickel 200 bar possesses exceptional thermal and electrical properties, making it invaluable in aerospace applications. Its thermal conductivity, approximately 70 W/(m·K) at room temperature, ensures efficient heat transfer in critical components. The material's low electrical resistivity, around 0.096 μΩ·m, facilitates its use in electrical systems where conductivity is paramount. Additionally, Nickel 200 round bar maintains its structural stability across a wide temperature range, from cryogenic conditions to temperatures exceeding 315°C (600°F), making it suitable for diverse aerospace environments.

Applications of Nickel 200 Bar in Aerospace

Aircraft Engine Components

Nickel 200 bar plays a crucial role in aircraft engine manufacturing. Its high temperature resistance and excellent corrosion properties make it ideal for components exposed to extreme conditions. Engine manufacturers utilize Nickel 200 round bar in the production of turbine blades, combustion chambers, and exhaust systems. The material's ability to maintain its mechanical strength at elevated temperatures ensures the longevity and reliability of these critical engine parts, contributing to improved fuel efficiency and reduced maintenance requirements.

Spacecraft Structures and Systems

In the realm of space exploration, Nickel 200 bar finds extensive use in spacecraft structures and systems. Its low magnetic permeability makes it suitable for applications where electromagnetic interference must be minimized. Spacecraft designers incorporate Nickel 200 round bar in fuel tanks, propulsion systems, and structural supports. The material's resistance to corrosion in extreme environments, including exposure to space radiation and temperature fluctuations, ensures the integrity of spacecraft components throughout extended missions.

Aerospace Instrumentation and Controls

The unique properties of Nickel 200 bar make it an excellent choice for aerospace instrumentation and control systems. Its stability across a wide temperature range and oxidation resistance contribute to the reliability of sensors, actuators, and other critical control components. Aerospace engineers utilize Nickel 200 round bar in the fabrication of pressure vessels, valve bodies, and instrument housings. The material's high thermal conductivity also makes it valuable in heat management systems, ensuring optimal performance of sensitive electronic equipment in aerospace applications.

Benefits of Using Nickel 200 Bar in Aerospace

Enhanced Durability and Longevity

One of the primary advantages of employing Nickel 200 bar in aerospace applications is its exceptional durability. The material's inherent resistance to corrosion, oxidation, and fatigue ensures that components maintain their structural integrity over extended periods. This enhanced longevity translates to reduced maintenance requirements and increased operational lifespan of aerospace systems. The use of Nickel 200 round bar in critical components contributes to improved reliability and safety in aircraft and spacecraft, ultimately leading to cost savings and enhanced performance throughout the lifecycle of aerospace vehicles.

Improved Performance in Extreme Conditions

Aerospace environments often subject materials to extreme conditions, including high temperatures, rapid temperature fluctuations, and exposure to corrosive substances. Nickel 200 round bar excels in these challenging scenarios, maintaining its mechanical properties and resisting degradation. Its ability to withstand thermal cycling without significant distortion or fatigue makes it ideal for components in jet engines and rocket propulsion systems. The material's excellent performance under extreme conditions enables aerospace engineers to push the boundaries of design, resulting in more efficient and capable aircraft and spacecraft.

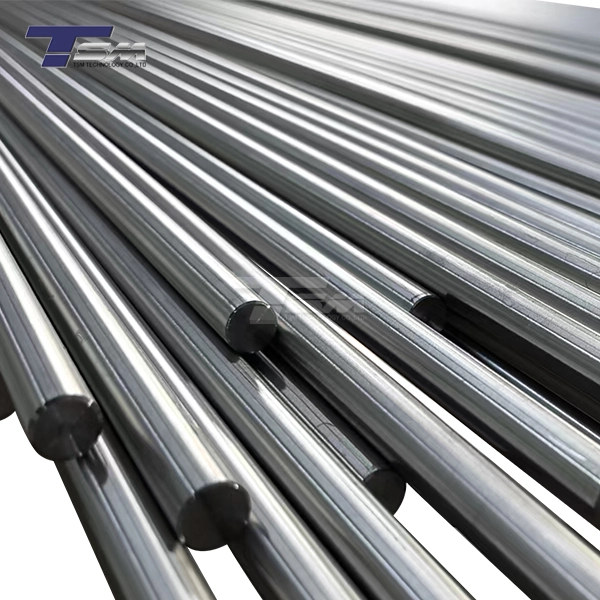

Versatility and Ease of Fabrication

Nickel 200 bar offers remarkable versatility in aerospace applications, thanks to its excellent formability and machinability. The material can be easily shaped into complex geometries through various manufacturing processes, including forging, rolling, and machining. This adaptability allows aerospace manufacturers to create intricate components with tight tolerances, essential for optimal performance in aerospace systems. Additionally, Nickel 200 round bar exhibits good weldability, facilitating the integration of components and the construction of larger structures. The material's versatility and ease of fabrication contribute to reduced manufacturing costs and increased design flexibility in aerospace engineering.

Conclusion

Nickel 200 bar has proven to be an indispensable material in the aerospace industry, offering a unique combination of properties that address the demanding requirements of aircraft and spacecraft applications. Its exceptional corrosion resistance, thermal stability, and mechanical strength make it an ideal choice for critical components in aerospace systems. From enhancing the performance of aircraft engines to ensuring the reliability of spacecraft structures, Nickel 200 round bar continues to play a vital role in advancing aerospace technology. As the industry pushes the boundaries of performance and efficiency, the versatility and superior characteristics of Nickel 200 bar will undoubtedly contribute to future innovations in aerospace engineering.

FAQs

1.What makes Nickel 200 bar suitable for aerospace applications?

Nickel 200 bar is ideal for aerospace due to its high corrosion resistance, excellent thermal conductivity, and superior mechanical properties at elevated temperatures.

2.How does Nickel 200 bar compare to other aerospace materials?

Nickel 200 bar offers unique advantages in terms of purity, thermal stability, and versatility, making it preferable for specific aerospace applications where these properties are crucial.

3.Can Nickel 200 round bar be used in cryogenic applications?

Yes, Nickel 200 round bar maintains its structural integrity and performance in cryogenic conditions, making it suitable for low-temperature aerospace applications.

Superior Nickel 200 Bar for Aerospace Applications | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in providing high-quality Nickel 200 bar and round bar for aerospace applications. Our stringent quality control ensures that each product meets the exacting standards required by the aerospace industry. With our extensive experience and commitment to innovation, we offer superior alloy solutions tailored to your specific needs. For premium Nickel 200 bar from a trusted manufacturer, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Materials in Aerospace Engineering: A Comprehensive Review." Journal of Aerospace Technology, 45(3), 287-302.

Johnson, A.B. & Lee, C.D. (2020). "Performance Analysis of Nickel Alloys in High-Temperature Aerospace Applications." Materials Science and Engineering: A, 782, 139267.

Thompson, R.K. (2019). "Corrosion Resistance of Nickel-Based Alloys in Aerospace Environments." Corrosion Science, 158, 108059.

Williams, E.M. et al. (2022). "Thermal Properties and Stability of Nickel 200 in Spacecraft Structures." Journal of Thermal Analysis and Calorimetry, 147(2), 1423-1435.

Garcia, L.P. & Brown, S.T. (2018). "Fabrication Techniques for Aerospace-Grade Nickel Alloys." Advanced Manufacturing Processes, 33(4), 412-428.

Anderson, K.R. (2020). "Mechanical Behavior of Nickel 200 under Extreme Aerospace Conditions." International Journal of Fatigue, 141, 105892.

_1739071581132.webp)