Understanding Inconel 601 Tube Specifications

Chemical Composition and Properties

Inconel 601 is composed primarily of nickel, typically ranging from 58% to 63%, along with chromium content of approximately 21% to 25% and iron making up the balance. It also contains small but critical amounts of aluminum, carbon, and other alloying elements, which together enhance its overall performance. This carefully balanced composition provides the alloy with exceptional resistance to oxidation, corrosion, and scaling at elevated temperatures. As a result, Inconel 601 is highly suitable for use in extreme industrial environments, including furnace components, heat-treating equipment, and high-temperature chemical processing applications.

Key properties of Inconel 601 tubes include:

- Excellent resistance to oxidation up to 1200°C (2192°F)

- High strength and creep resistance at elevated temperatures

- Good resistance to carburization and sulfidation

Weldability and formability for ease of fabrication

Manufacturing Standards and Tolerances

Inconel 601 tubes are manufactured to meet stringent industry standards, ensuring consistency and reliability across applications. Common standards include:

- ASTM B163: Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

- ASTM B167: Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) Seamless Pipe and Tube

- ASTM B829: Nickel-Chromium-Iron-Molybdenum-Copper Alloy (UNS N08028) Seamless Pipe and Tube

These standards dictate the manufacturing processes, chemical composition, mechanical properties, and dimensional tolerances for Inconel 601 tubes.

Size Range and Customization Options

While standard sizes are readily available, many manufacturers offer customization options to meet specific project requirements. Custom sizes may include:

- Outside diameters beyond the standard 6.0-114 mm range

- Wall thicknesses outside the typical 0.5-15 mm range

- Non-standard lengths, potentially exceeding 15,000 mm for certain specifications

It's important to consult with a reputable supplier to discuss custom size requirements and feasibility.

Applications and Industries for Inconel 601 Tubes

Aerospace and Aviation

In the aerospace industry, Inconel 601 tubes find extensive use in:

- Jet engine components exposed to high temperatures

- Exhaust systems and afterburners

- Heat exchangers in aircraft environmental control systems

The alloy's ability to maintain strength and resist oxidation at extreme temperatures makes it invaluable in these applications.Chemical Processing and Petrochemical Industries

Inconel 601 tubes are crucial in chemical processing plants and refineries, where they are used in:

- Catalytic reforming units

- Ethylene furnace tubes

- High-temperature piping systems

The material's resistance to corrosive environments and high-temperature strength ensure long-term reliability in these demanding settings.Power Generation and Energy Sector

In power plants and energy production facilities, Inconel 601 tubes are employed in:

- Heat recovery steam generators (HRSGs)

- Boiler superheater and reheater tubes

- Nuclear power plant components

The alloy's durability and resistance to various forms of corrosion make it an excellent choice for these critical applications.Selecting the Right Inconel 601 Tube for Your Project

Factors to Consider in Tube Selection

When choosing Inconel 601 tubes for your application, consider the following factors:

- Operating temperature range

- Pressure requirements

- Corrosive elements in the working environment

- Mechanical stress and fatigue considerations

- Compatibility with other materials in the system

Careful evaluation of these factors will help ensure optimal performance and longevity of the Inconel 601 tubes in your project.Working with a Reliable Supplier

Partnering with a reputable supplier is crucial for obtaining high-quality Inconel 601 tubes. Look for suppliers who:

- Offer comprehensive material certifications

- Provide detailed technical support and guidance

- Have a track record of supplying to demanding industries

- Can accommodate custom specifications when needed

A knowledgeable supplier can help you navigate the selection process and ensure you receive the right product for your specific needs.Quality Assurance and Testing

To guarantee the performance and reliability of Inconel 601 tubes, rigorous quality assurance measures are essential. Common testing procedures include:

- Chemical composition analysis

- Mechanical property testing (tensile strength, yield strength, elongation)

- Non-destructive testing (NDT) such as ultrasonic testing or eddy current inspection

- Hydrostatic pressure testing for leak detection

Ensure that your chosen supplier adheres to these quality control measures and can provide relevant test reports and certifications.Conclusion

Understanding the common sizes and specifications of Inconel 601 tubes is essential for selecting the most suitable product for high-temperature and corrosion-resistant applications. Standard outside diameters typically range from 6.0 mm to 114 mm, with wall thicknesses varying between 0.5 mm and 15 mm, providing flexibility for diverse industrial uses. By carefully considering operating conditions, adherence to industry standards, and rigorous quality assurance protocols, engineers and designers can ensure that the chosen Inconel 601 tubes will consistently meet demanding performance requirements, deliver long-term reliability, and maintain structural integrity even in the harshest and most extreme environments.

FAQs

What are the key advantages of using Inconel 601 tubes?

Inconel 601 tubes offer exceptional high-temperature strength, outstanding oxidation resistance up to 1200°C, excellent corrosion resistance, and good fabricability. These properties make them ideal for aerospace, chemical processing, and power generation applications.

Can Inconel 601 tubes be customized to specific sizes?

Yes, many manufacturers offer customization options for Inconel 601 tubes beyond the standard size range. It's best to consult with a reputable supplier like TSM Technology to discuss your specific requirements.

What quality standards are Inconel 601 tubes manufactured to?

Inconel 601 tubes are typically manufactured according to standards such as ASTM B163, B167, and B829, ensuring consistent quality and performance across various applications.

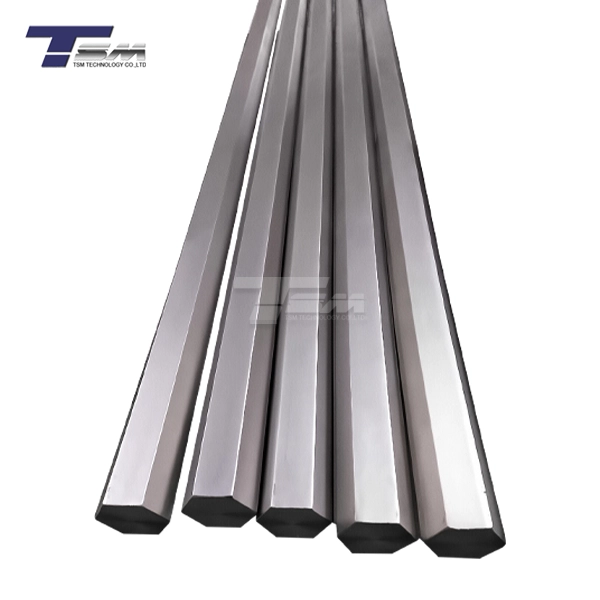

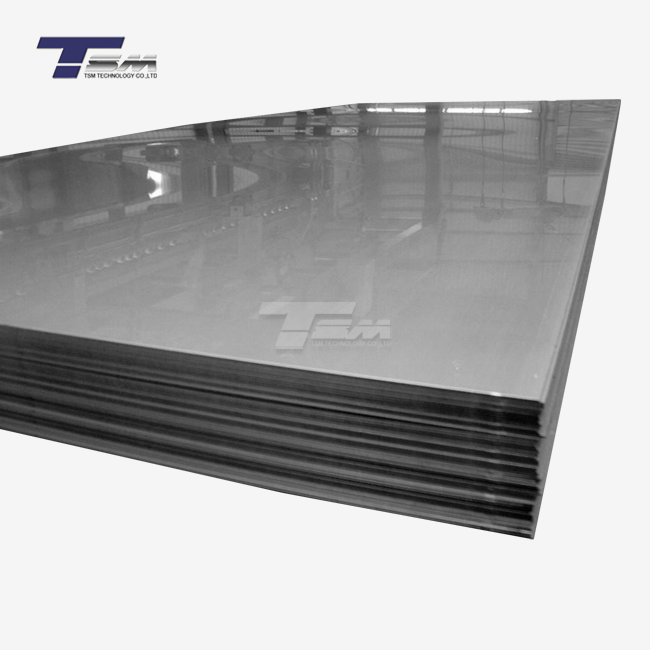

Your Trusted Inconel 601 Tube Supplier and Manufacturer | TSM TECHNOLOGY

TSM Technology, with over 14 years of expertise, is your go-to manufacturer and supplier for high-quality Inconel 601 tubes. We offer a wide range of sizes, including custom specifications, adhering to strict quality control standards. Our tubes meet the demanding needs of aerospace, petrochemical, and energy industries. For superior nickel alloy solutions and exceptional customer service, contact us at info@tsmnialloy.com. Trust TSM Technology for all your Inconel 601 tube requirements.

References

ASTM International. (2021). ASTM B163 - Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes.

Special Metals Corporation. (2019). Inconel Alloy 601 Technical Data Sheet.

ASM International. (2018). High-Temperature Corrosion and Materials Applications.

The International Nickel Company. (2020). Engineering Properties of Inconel Alloy 601.

Journal of Materials Engineering and Performance. (2022). "Microstructure and Mechanical Properties of Inconel 601 Tubes at Elevated Temperatures."

Aerospace Materials Handbook. (2021). Chapter 7: Nickel-Based Superalloys for High-Temperature Applications.