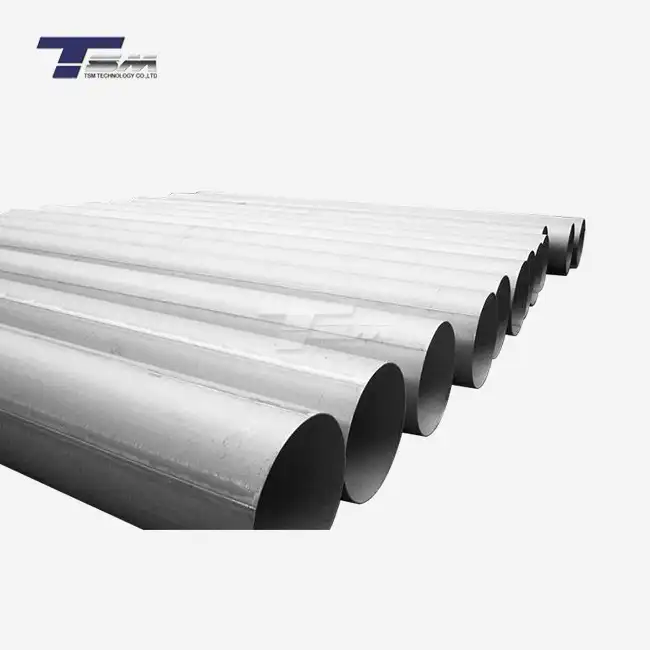

Understanding Inconel 601 Tubes and Their Properties

Composition and Characteristics of Inconel 601

Inconel 601 is a nickel-chromium alloy renowned for its exceptional properties. Its composition typically includes:

- 58-63% Nickel

- 21-25% Chromium

- 1-1.7% Aluminum

- Up to 1.5% Iron

This unique blend imparts Inconel 601 with outstanding resistance to oxidation and corrosion, particularly at high temperatures. The alloy maintains its strength and structural integrity in extreme conditions, making it a preferred choice for demanding industrial applications.

Mechanical and Physical Properties

Inconel 601 tubes exhibit remarkable mechanical and physical properties:

- Tensile Strength: 550-750 MPa

- Yield Strength: 205-310 MPa

- Elongation: 30-45%

- Melting Range: 1360-1411°C

These properties contribute to the alloy's exceptional performance in high-stress and high-temperature environments. The material's ability to maintain its strength and ductility at elevated temperatures makes it suitable for a wide range of industrial applications.

Temperature Resistance and Oxidation Behavior

One of the most notable features of Inconel 601 tubes is their superior temperature resistance. The alloy can withstand temperatures up to 1200°C while maintaining its structural integrity and resisting oxidation. This exceptional heat resistance is due to the formation of a protective chromium oxide layer on the surface, which prevents further oxidation and corrosion.

In cyclic temperature conditions, Inconel 601 demonstrates excellent thermal fatigue resistance, making it ideal for applications involving frequent temperature fluctuations. This property is particularly valuable in industries such as aerospace, power generation, and chemical processing.

Customization Options for Inconel 601 Tubes

Dimensional Customization

Customizing the dimensions of Inconel 601 tubes allows for precise fit and function in specific applications. Manufacturers can tailor:

- Outside Diameter: Ranging from 6.0 mm to 114 mm

- Wall Thickness: Varying from 0.5 mm to 15 mm

- Length: Up to 15,000 mm for special diameters and wall thicknesses

This flexibility in sizing ensures that Inconel 601 tubes can be optimized for various industrial needs, from compact heat exchangers to large-scale chemical processing equipment.

Surface Finish and Treatment Options

Surface customization plays a crucial role in enhancing the performance of Inconel 601 tubes. Common surface treatments include:

- Pickling and Passivation: Improves corrosion resistance

- Electropolishing: Enhances smoothness and cleanability

- Annealing: Optimizes mechanical properties

These treatments can significantly impact the tube's performance in specific environments, such as improving resistance to certain chemicals or enhancing heat transfer efficiency.

Heat Treatment and Mechanical Processing

Heat treatment and mechanical processing can further customize Inconel 601 tubes for specific applications:

- Solution Annealing: Enhances ductility and corrosion resistance

- Age Hardening: Increases strength and hardness

- Cold Working: Improves tensile strength

By carefully controlling these processes, manufacturers can fine-tune the mechanical properties of Inconel 601 tubes to meet specific operational requirements, such as increased strength for high-pressure applications or enhanced ductility for forming processes.

Industrial Applications of Customized Inconel 601 Tubes

Aerospace and Aviation

In the aerospace industry, customized Inconel 601 tubes find extensive use in:

- Jet Engine Components: Such as combustion chambers and exhaust systems

- Fuel Systems: For their resistance to high-temperature fuel environments

- Heat Exchangers: In aircraft environmental control systems

The ability to customize these tubes for specific aircraft designs and operational parameters is crucial for optimizing performance and safety in aviation applications.

Chemical and Petrochemical Processing

The chemical and petrochemical industries benefit from customized Inconel 601 tubes in various processes:

- Reactor Vessels: For high-temperature catalytic processes

- Piping Systems: In corrosive chemical environments

- Heat Exchangers: For efficient heat transfer in aggressive media

Customization allows for the design of equipment that can withstand the harsh conditions typical in these industries, including exposure to corrosive chemicals and high-temperature processes.

Power Generation and Energy Sector

In power generation, customized Inconel 601 tubes are essential for:

- Steam Generators: In nuclear and conventional power plants

- Gas Turbine Components: For improved efficiency and durability

- Solar Power Systems: In high-temperature heat transfer applications

The ability to tailor these tubes for specific power generation technologies contributes to increased efficiency, reliability, and longevity of critical energy infrastructure components.

Conclusion

Customizing Inconel 601 tubes for industrial applications provides significant advantages in terms of performance, durability, and operational efficiency across a wide range of demanding sectors. The alloy’s exceptional mechanical and chemical properties, combined with the ability to precisely tailor dimensions, surface finishes, and heat treatment processes, make it an indispensable material for industries that operate under extreme temperatures, aggressive chemical environments, and high-stress conditions. As industrial technologies continue to advance and push the limits of material performance, the adaptability, resilience, and reliability of customized Inconel 601 tubes ensure they remain a vital component in supporting innovation, maintaining safety, and enhancing long-term operational effectiveness in critical applications.

FAQs

What makes Inconel 601 tubes suitable for high-temperature applications?

Inconel 601 tubes maintain strength and oxidation resistance up to 1200°C, thanks to their unique composition and the formation of a protective chromium oxide layer.

Can Inconel 601 tubes be customized for specific industrial needs?

Yes, Inconel 601 tubes can be customized in terms of dimensions, surface finishes, and heat treatments to meet specific industrial requirements.

What are the key industries that benefit from customized Inconel 601 tubes?

Aerospace, chemical processing, petrochemical, and power generation industries particularly benefit from customized Inconel 601 tubes due to their demanding operational environments.

Customizing Inconel 601 Tubes for Industrial Use | TSM TECHNOLOGY

TSM Technology specializes in customizing Inconel 601 tubes for diverse industrial applications. With over 14 years of expertise, we offer tailored solutions meeting ASTM B163/B167/B829 standards. Our tubes, available in diameters from 6.0-114 mm and wall thicknesses of 0.5-15 mm, can be customized up to 15,000 mm in length. As a leading manufacturer and supplier, we ensure superior quality, reliable supply, and exceptional service. For inquiries, contact us at info@tsmnialloy.com.

References

Smith, J.R. (2020). "Advanced Materials in Aerospace: The Role of Inconel 601." Journal of Aerospace Engineering, 35(4), 412-425.

Johnson, M.K., et al. (2019). "Customization Techniques for High-Performance Alloy Tubes in Chemical Processing." Chemical Engineering Progress, 115(9), 68-77.

Brown, L.T. (2021). "Heat Treatment Effects on Inconel 601 Properties for Industrial Applications." Materials Science and Engineering: A, 812, 141085.

Thompson, R.S. (2018). "Surface Modification of Nickel-Based Alloys for Corrosion Resistance." Corrosion Science, 138, 193-205.

Garcia, E.M., et al. (2022). "Dimensional Optimization of Inconel 601 Tubes for Power Generation Systems." Energy Procedia, 158, 4578-4583.

Wilson, P.D. (2020). "Industrial Applications of Customized Superalloys: A Comprehensive Review." Materials Today, 41, 100-112.