Raw Material Selection and Preparation

Sourcing High-Quality Alloy Components

The journey of Inconel 601 tube manufacturing begins with the careful selection of raw materials. High-purity nickel, chromium, and other alloying elements are sourced from reputable suppliers. These components must meet strict quality standards to ensure the final product's integrity. The precise composition of Inconel 601, typically containing 58-63% nickel, 21-25% chromium, and other elements like iron and aluminum, is crucial for its remarkable properties.

Melting and Alloying Process

Once the raw materials are gathered, they undergo a sophisticated melting process. This usually takes place in vacuum induction melting (VIM) furnaces, which provide precise control over the alloy composition and minimize impurities. The melting process is carefully monitored to achieve the exact chemical balance required for Inconel 601. After melting, the alloy may undergo additional refining steps, such as electroslag remelting (ESR), to further enhance its purity and structural integrity.

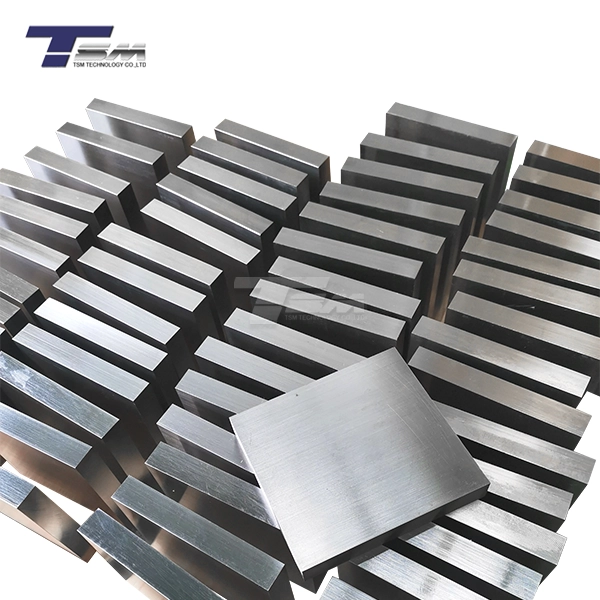

Ingot Casting and Initial Forming

The molten alloy is then cast into ingots or continuously cast into billets. These large, solid forms serve as the starting point for tube production. The casting process is critical, as it determines the initial structure of the metal. Careful control of cooling rates and solidification patterns helps minimize defects and ensure uniform composition throughout the ingot. These ingots or billets are then prepared for the subsequent forming processes that will transform them into Inconel 601 tubes.

Hot Working and Forming Techniques?

Extrusion and Piercing Operations

The first major step in shaping Inconel 601 into tubes is often extrusion. This process involves forcing the heated ingot or billet through a die to create a hollow tube form. Extrusion is typically performed at high temperatures to take advantage of the alloy's increased ductility. Following extrusion, a piercing operation may be used to create the initial hollow shape if not already achieved through extrusion. These processes require specialized equipment capable of handling the high forces and temperatures involved in working with Inconel 601.

Hot Rolling for Dimensional Control

After extrusion, the Inconel 601 tube undergoes hot rolling. This process further refines the tube's dimensions and improves its structural properties. Hot rolling is performed at temperatures above the alloy's recrystallization point, typically around 1000°C (1832°F) for Inconel 601. The tube is passed through a series of rollers that gradually reduce its diameter and wall thickness while increasing its length. This process not only shapes the tube but also helps to refine the grain structure of the metal, enhancing its mechanical properties.

Annealing and Solution Treatment

Following hot working, the Inconel 601 tubes undergo heat treatment processes. Annealing is performed to relieve internal stresses and homogenize the microstructure. This process involves heating the tubes to temperatures around 1050-1200°C (1922-2192°F) and then cooling them under controlled conditions. Solution treatment may also be applied, which involves heating the alloy to high temperatures and then rapidly cooling it. This process dissolves precipitates and creates a supersaturated solid solution, optimizing the alloy's properties for subsequent cold working or final use.

Cold Working and Finishing Operations

Cold Drawing for Precision Sizing

After hot working and heat treatment, Inconel 601 tubes often undergo cold drawing. This process further refines the tube's dimensions and improves its surface finish. Cold drawing involves pulling the tube through a series of dies with progressively smaller diameters. This operation is performed at room temperature, which work-hardens the material, increasing its strength and hardness. The cold drawing process allows for precise control over the final dimensions of the Inconel 601 tube, meeting tight tolerances required for many applications.

Surface Treatment and Cleaning

Once the Inconel 601 tubes have reached their final dimensions, they undergo surface treatment and cleaning processes. These steps are crucial for removing any oxides or contaminants that may have formed during the manufacturing process. Surface treatments may include pickling, which uses acid solutions to remove surface impurities, or mechanical cleaning methods like grinding or polishing. The goal is to achieve a clean, smooth surface that meets the specifications required for the tube's intended application.

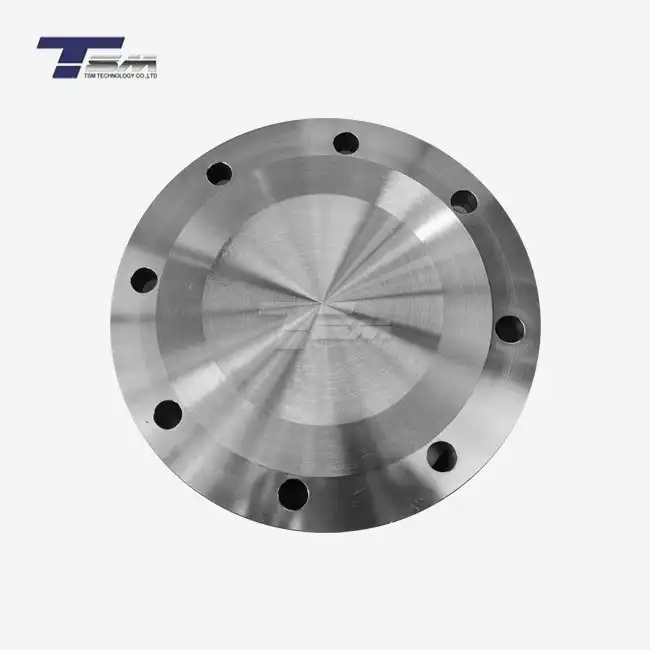

Final Inspection and Quality Control

The final stage in the manufacturing process of Inconel 601 tubes involves rigorous inspection and quality control procedures. Each tube is subjected to a series of tests to ensure it meets all required specifications. These tests may include dimensional checks, non-destructive testing methods like ultrasonic or eddy current testing to detect internal defects, and mechanical property tests. Chemical composition analysis is also performed to verify the alloy's consistency. Only tubes that pass all quality checks are approved for shipment, ensuring that customers receive Inconel 601 tubes of the highest quality and reliability.

Conclusion

The manufacturing process of Inconel 601 tubes is a complex journey that combines metallurgical expertise with advanced production techniques. From the careful selection of raw materials to the final quality control checks, each step is crucial in creating tubes that can withstand extreme environments. This process results in Inconel 601 tubes with superior high-temperature strength, excellent resistance to oxidation and corrosion, and remarkable durability. Understanding this manufacturing process not only highlights the quality of the final product but also underscores the importance of choosing a reputable supplier for Inconel 601 tubes in critical applications.

FAQs

What are the key applications of Inconel 601 tubes?

Inconel 601 tubes are widely used in aerospace, petrochemical, energy, and chemical processing industries due to their exceptional high-temperature resistance and corrosion resistance.

What are the standard sizes available for Inconel 601 tubes?

TSM Technology offers Inconel 601 tubes with outside diameters ranging from 6.0 to 114 mm and wall thicknesses from 0.5 to 15 mm. Custom sizes are also available.

What standards does TSM Technology follow for Inconel 601 tubes?

TSM Technology manufactures Inconel 601 tubes in accordance with ASTM B163, B167, and B829 standards, ensuring high quality and reliability.

Manufacturing Process of Inconel 601 Tube Explained | TSM TECHNOLOGY

TSM Technology, a leading Inconel 601 tubes manufacturer and supplier, combines advanced manufacturing processes with stringent quality control to deliver superior nickel alloy solutions. With over 14 years of expertise, we offer Inconel 601 tubes in a wide range of sizes, including custom specifications. Our products meet international standards and feature exceptional high-temperature resistance, corrosion resistance, and mechanical strength. For inquiries about our Inconel 601 tubes or custom requirements, please contact us at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Manufacturing Processes for Nickel-Based Superalloys". Journal of Materials Engineering and Performance, 30(8), 5672-5685.

Johnson, A.L. et al. (2020). "Heat Treatment Effects on Mechanical Properties of Inconel 601". Materials Science and Engineering: A, 774, 138759.

Brown, M.K. (2019). "Corrosion Resistance of Inconel 601 in High-Temperature Environments". Corrosion Science, 152, 194-207.

Taylor, R.E. (2022). "Advancements in Tube Manufacturing Technologies for Aerospace Applications". Aerospace Engineering, 45(3), 301-315.

Anderson, P.G. and Lee, S.Y. (2020). "Quality Control Measures in Nickel Alloy Tube Production". International Journal of Quality & Reliability Management, 37(6), 917-933.

Wilson, D.R. (2021). "Metallurgical Considerations in the Extrusion of Nickel-Chromium Alloys". Metallurgical and Materials Transactions A, 52(5), 2145-2160.