- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

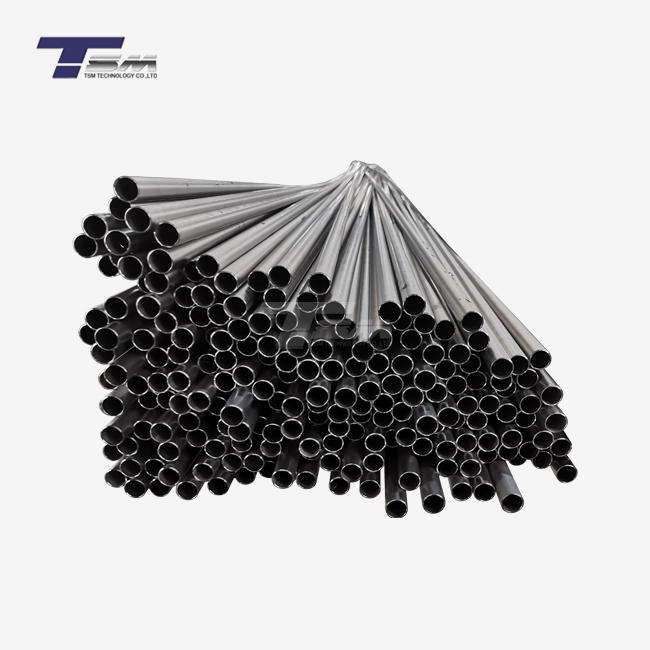

Custom Inconel 617 Round Bars: Sizes, Tolerances, and Lead Time

When looking for custom Inconel 617 round bars for mission-critical uses, it's very important to understand how material specs, manufacturing tolerances, and shipping times all work together. These nickel-chromium-cobalt-molybdenum superalloy bars work very well in very hot places (up to 1200°C), which is why they are essential for power generation systems, petrochemical processing equipment, and engine parts for airplanes. You can change the diameter from 5mm to 300mm, and the accuracy is within 0.05mm. Lead times are usually between 4 and 12 weeks, but they depend on how complicated the specifications are and how many orders are placed.

Understanding Custom Inconel 617 Round Bar Specifications

To have a successful procurement plan, you need to know exactly what properties of the material make Inconel 617 perform better than other materials. The chemical makeup of this nickel-based superalloy provides a synergistic effect that makes it very reliable in harsh industrial settings.

Chemical Composition and Performance Enhancement

Inconel 617's amazing high-temperature traits come from the way its elements are carefully balanced. Nickel content between 44-52% keeps the matrix stable, and chromium content between 20 and 23% makes it very resistant to rust. Adding 12–15% cobalt makes the material stronger against creep, and adding 8–10% molybdenum makes it less likely to rust in reducing conditions.

Because these parts work together, the minimum tensile strength is 760 MPa, the minimum yield strength is 350 MPa, and the minimum stretch property is 30%. The material is very good for precise cutting because it is 8.42 g/cm³ dense and has a maximum Brinell hardness of 241 when it is annealed.

Standard Sizes and Custom Dimensions

As per ASTM B166, ASME SB166, and EN 10095 standards, TSM Technology makes Inconel 617 round bars. Our normal diameter range is from 5 mm to 300 mm, and our length range is from 3000 mm to 6000 mm. Our three manufacturing sites use specialized forging processes that allow us to make parts in any size up to 500 mm in diameter.

85 CNC lathes with AS9100D certification are used in the precise production process to make sure that each bar meets the strict tolerances needed for aerospace applications. Our special thermomechanical process, which we came up with after a lot of study, gives our grades 15% more creep rupture strength than regular ones.

Critical Tolerance Requirements

Controlling manufacturing tolerances has a direct effect on how well downstream cutting works and how well components work. Our normal tolerance of ±0.05mm meets the strict needs of nuclear heat exchangers and combustion chambers in spacecraft. You can get a surface finish that is peeled or turned, ground, or polished, all of which meet AMS 2701 standards.

Sandblasting and anodizing are two surface processes that can improve performance even more for certain uses. For each surface treatment, optical emission spectrometry and a full set of mechanical testing methods are used to make sure the quality is high.

Lead Time Considerations for Custom Inconel 617 Round Bars

Scheduling production for nickel-based superalloys is hard because it requires a lot of juggling between the availability of raw materials, the manufacturing capacity, and the quality certification standards. When procurement teams understand these factors, they can make their sourcing methods work better.

Factors Affecting Production Schedules

Lead times for custom items are affected by a number of important factors. The main variable is the availability of raw materials, especially for complex mixtures that need pure nickel and exact alloying elements. Our strategic inventory management keeps pre-certified stock on hand for pressing needs, which helps us meet our 98% on-time delivery rate for orders over 50 tons.

Manufacturing complexity increases proportionally with customization requirements. Standard diameter Inconel 617 round bars from stock usually ship within two to four weeks. Custom sizes that need special tools may take eight to twelve weeks. Heat treatment cycles, which are needed to get the best mechanical qualities, add 3–5 days to the time it takes to make something.

Quality Certification Impact

Comprehensive quality assurance methods add a lot of time to the overall lead time, but they make sure that materials can be tracked and that their performance is confirmed. Our three-step inspection process includes checking the PMI of the raw materials, keeping an eye on the sizes while they're being made, and finally using ultrasonic and radiographic tests to find flaws as small as 0.02mm.

Each shipment comes with material test certificates and SGS test reports, which are full proof for use in nuclear and aerospace uses. Digital QC reports that use blockchain technology give you secure API connections to view certification data in real time.

Optimization Strategies

Early engagement with suppliers and clear sharing of requirements are key to good lead time management. During the design process, our technical consulting services help you choose the best materials and meet the most stringent size and shape requirements. This could cut down on the need for custom manufacturing.

Strategic relationships with qualified suppliers let you plan for volume and get inventory ready for projects that will happen again and again. Our annual capacity of 1,500 tons or more supports large-scale energy projects, and our spread production network lets us handle smaller, more specialized orders as well.

Comparing Inconel 617 Round Bars with Alternative Alloys

Choosing the right materials has a big effect on both how well the project works and how much it costs, especially in high-temperature service settings. A full comparison of alloys lets you make smart choices that balance practical needs with cost concerns.

Performance Characteristics Analysis

Compared to Inconel 625, Inconel 617 is better at resisting rusting, especially at temperatures above 1000°C. Inconel 718 is stronger at room temperature, but it can only be used up to 650°C, which means it can't be used in gas engine hot sections where Inconel 617 keeps the structure strong.

Inconel 617 is better for cyclic heating uses in aerospace engines than Inconel 600 because it has more cobalt, which makes it more resistant to thermal fatigue. The nickel-based matrix is better at resisting creep than stainless steels like 310SS and keeps its mechanical qualities at high temperatures.

Cost-Benefit Considerations

Titanium alloys have the advantage of being less dense, but they don't have the oxidation protection needed for long-term exposure to high temperatures. Even though Inconel 617 round bar costs more at first, it usually ends up being worth it because it lasts longer and needs less upkeep in tough situations.

Alloy 800H has about the same high-temperature strength as steel, but it costs less and doesn't fight corrosion as well in sulfur-containing environments like those found in petrochemical processing. The better performance of 617 makes it worth specifying in important situations where failure would have far-reaching effects that are more important than material cost.

Machining, Welding, and Handling of Custom Inconel 617 Round Bars

Due to its high strength and ability to work-harden, Inconel 617 needs to be processed using specific methods to get the best results. The right way to handle materials protects their integrity and increases the speed of production.

Precision Machining Guidelines

For machining processes to go well, the right tools must be chosen and parameters must be optimized. Positive rake angles on carbide cutting tools keep the work from hardening too much, and controlled cutting speeds keep the material from getting too hot, which can change its qualities.

Flood coolant systems maintain consistent temperatures during extended machining cycles. From our experience in production, we know that keeping surface speeds between 50 and 80 meters per minute and feed rates of 0.1 to 0.2 mm per revolution will make tools last longer and meet surface finish standards.

Welding Best Practices

Gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are both great ways to join pieces of Inconel 617 together. The composition and mechanical features of Inconel 617 filler metal stay the same across weld joints.

For thick parts, preheating needs to be between 150°C and 200°C, and temperatures between passes must stay below 200°C to avoid carbide precipitation. A heat treatment at 1175°C after welding, followed by quick cooling, improves the resistance to corrosion and the mechanical qualities.

Quality Control Protocols

Coordinate measuring tools are used for dimension verification, which makes sure that production stays within the allowed ranges. The measurement of surface finish proves the accuracy of the machining parameters and the machine's suitability for further manufacturing operations.

Ultrasonic screening and magnetic particle examination are two types of non-destructive testing that can find internal breaks and surface flaws. From the certification of the raw materials to the documentation of the final inspection, our quality control system keeps full traceability.

Procurement and Sourcing Strategy for Inconel 617 Round Bars

For sourcing to work well, suppliers need to be carefully evaluated based on their technical skills, quality processes, and delivery performance. Strategic agreements improve the dependability of the supply chain and lower the total cost of ownership.

Supplier Evaluation Criteria

Meeting certification requirements is a basic need for nuclear and aerospace uses. The AS9100D aerospace quality management and ISO 9001 quality processes show that they are dedicated to meeting high standards of performance.

An evaluation of manufacturing capacity looks at the capabilities of the equipment, the amount of work that can be done, and the availability of technical help. Our three sites and eight production lines give us backup and the ability to adapt to different order needs while keeping quality standards high.

Order Planning Considerations

Minimum order numbers usually show how economically production runs and how well materials are used. Custom diameter needs may mean buying specialty tools, especially for sizes that aren't standard and are bigger than 300 mm in diameter.

Structures that set prices based on volume reward strategic buying patterns and long-term commitments. Early involvement in the planning stages of a project allows for the best placement of goods and lowers the cost of expediting for urgent needs.

Value-Added Services

Comprehensive material solutions include more than just supplying round Inconel 617 round bars. They also offer custom cutting, heat treatment optimization, and surface preparation services. These features make the supply chain simpler while still making sure that processes work together and quality is always the same.

Technical advice services help with choosing the right materials, making sure that specifications are met, and providing application engineering support. Our 14 years of specialized experience in metalworking has given us the ability to come up with creative solutions for difficult problems, such as H2S-resistant versions for sour gas service.

TSM Technology: Your Trusted Inconel 617 Round Bar Solutions Provider

TSM Technology stands as a premier manufacturer and supplier of high-performance Inconel 617 round bars, serving global markets with unwavering commitment to quality and innovation. Our comprehensive capabilities span custom manufacturing, precision machining, and technical consultation services tailored to demanding aerospace, energy, and petrochemical applications.

Manufacturing Excellence and Capacity

Our advanced manufacturing infrastructure encompasses three strategically located facilities operating eight dedicated production lines equipped with over 100 precision machines. This distributed capacity ensures supply chain resilience while maintaining consistent quality standards across all production locations.

AS9100D aerospace certification validates our quality management systems and demonstrates capability to meet the stringent requirements of mission-critical applications. Each facility maintains comprehensive testing laboratories equipped with optical emission spectrometers, tensile testing equipment, and non-destructive testing capabilities.

Technical Innovation and Development

Continuous investment in research and development has yielded proprietary thermomechanical processing techniques that enhance material performance beyond conventional standards. Our specialized H2S-resistant 617M variant addresses specific challenges in sour gas service environments, demonstrating our commitment to application-specific solutions.

Collaborative partnerships with leading aerospace manufacturers and energy companies drive ongoing innovation in alloy development and processing optimization. This industry engagement ensures our products meet evolving performance requirements while maintaining cost-effectiveness.

Global Distribution and Support

Our international presence, established since 2011, enables responsive service delivery across 70+ countries through CITES/DFARS-compliant logistics networks. Regional distribution centers maintain strategic inventory levels while providing local technical support and customer service.

Digital integration including blockchain-based material certificates and API-accessible quality documentation streamlines procurement processes while ensuring complete traceability. Free sample programs enable material validation and application testing before full-scale orders.

Conclusion

Custom Inconel 617 round bars represent a critical material solution for industries demanding exceptional high-temperature performance and corrosion resistance. The intricate balance between material specifications, manufacturing tolerances, and delivery schedules requires careful coordination between procurement teams and qualified suppliers. TSM Technology's comprehensive manufacturing capabilities, technical expertise, and global distribution network provide the foundation for successful project execution across aerospace, energy, and petrochemical sectors. Our commitment to quality, innovation, and customer service ensures reliable material supply while supporting the demanding performance requirements of modern industrial applications.

FAQ

1.What is the maximum diameter available for custom Inconel 617 round bars?

TSM Technology manufactures Inconel 617 round bars with standard diameters ranging from 5mm to 300mm. Custom dimensions up to 500mm diameter are achievable through our specialized forging capabilities, depending on specific length and tolerance requirements.

2.What are typical lead times for custom Inconel 617 round bar orders?

Lead times vary based on customization complexity and order volume. Standard diameter bars from existing stock typically ship within 2-4 weeks, while custom dimensions may require 8-12 weeks. Large volume orders and specialized requirements may extend to 16 weeks including comprehensive quality certification.

3.Which international standards apply to TSM Technology's Inconel 617 round bars?

Our products conform to ASTM B166, ASME SB166, and EN 10095 international standards. All materials are manufactured under AS9100D aerospace quality certification with complete material test certificates and SGS test reports available for traceability and compliance verification.

4.What surface treatments are available for Inconel 617 round bars?

We offer multiple surface treatment options including sandblasting and anodizing to enhance performance characteristics for specific applications. Standard surface finishes include peeled/turned, ground, or polished conditions complying with AMS 2701 specifications.

5.How does TSM Technology ensure material quality and traceability?

Our comprehensive quality assurance protocol includes three-stage inspection: raw material PMI verification, in-process dimensional monitoring with ±0.05mm tolerance control, and final ultrasonic/radiographic testing. Digital QC reports with blockchain technology provide secure access to complete certification documentation.

Partner with TSM Technology for Superior Inconel 617 Round Bar Solutions

TSM Technology delivers unmatched expertise in custom Inconel 617 round bar manufacturing, combining 14+ years of specialized experience with state-of-the-art production capabilities. Our AS9100D-certified facilities ensure precision tolerance control and reliable delivery schedules for your critical aerospace and energy applications. As a trusted Inconel 617 round bar supplier, we provide comprehensive technical consultation, custom sizing options, and complete quality documentation to support your project success. Connect with our materials specialists today at info@tsmnialloy.com for detailed specifications and competitive pricing tailored to your specific requirements.

References

American Society for Testing and Materials. "Standard Specification for Nickel-Chromium-Cobalt-Molybdenum Alloy Rod and Bar." ASTM B166-19, West Conshohocken, PA: ASTM International, 2019.

Davis, Joseph R. "Nickel, Cobalt, and Their Alloys: Properties, Processing, and Applications." ASM International Handbook Series, Materials Park, OH: ASM International, 2000.

Donachie, Matthew J. and Donachie, Stephen J. "Superalloys: A Technical Guide, Second Edition." ASM International Materials Engineering Series, Materials Park, OH: ASM International, 2002.

Hayes, Robert W. "High Temperature Materials for Aerospace and Industrial Power." Metallurgical Society Conference Proceedings, Warrendale, PA: The Metallurgical Society, 1987.

Kear, Bernard H. "Advances in High Temperature Structural Materials and Protective Coatings." National Academy Press Engineering Materials Advisory Board, Washington, DC: National Academy Press, 1992.

Sims, Chester T., Stoloff, Norman S., and Hagel, William C. "Superalloys II: High-Temperature Materials for Aerospace and Industrial Power." John Wiley & Sons Materials Science and Engineering Series, New York: John Wiley & Sons, 1987.

Learn about our latest products and discounts through SMS or email

_1739071678907.webp)