- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Cutting Monel 401: Best Practices for Sawing and Waterjet Cutting

Cutting Monel 401 is hard and needs special methods to keep the alloy's unique qualities. The Monel 401 bar is made of a strong nickel-copper metal that is known for being resistant to corrosion and having high mechanical strength. When cutting it, it is important to carefully consider the cutting settings so that the material stays intact. Sawing and waterjet cutting are two effective ways to cut materials that can have a big effect on how well parts work in marine, aircraft, and chemical processing uses. Knowing the best ways to do things helps engineers get accurate results while reducing waste and keeping the alloy's great qualities that make it essential in tough industrial settings.

Understanding Monel 401 Bar: Properties and Challenges in Cutting

Nickel-copper alloys have special properties because of their unique makeup, which can be both helpful and difficult when they are being machined. Monel 401 is highly sought after for important uses because it has a minimum tensile strength of 760 MPa and a minimum yield strength of 345 MPa. However, these same properties can make cutting more difficult.

Material Composition and Mechanical Characteristics

Some 63% of Monel 401 is nickel and the other 28% to 34% is copper. This makes it a work-hardening metal that gets harder to cut as it is processed. This unique makeup gives the material great rust resistance in seawater and reduces acids. However, the high nickel content makes tools wear out quickly when used in normal cutting operations. Engineers can choose the best cutting settings and tools to get the best results by understanding these basic qualities.

The highest toughness of the metal, 75 HRB when it is annealed, makes Monel 401 bar very durable in service uses but makes it hard to remove material efficiently. Also, because Monel 401 is a thermal conductor, it needs to be carefully managed during cutting to keep the dimensions accurate and avoid work hardening.

Common Cutting Challenges and Solutions

When cutting nickel-copper metals, the biggest problem is generating heat. Too much heat can change the qualities of the material and harden the surfaces so they can't be cut any further. To get good cutting results, the following important things must be taken care of:

- Controlled cutting speeds and enough cooling keep the work from becoming too hard.

- Optimizing the choice of tools to reduce friction and heat buildup

- Controlling the feed rate to keep chip formation uniform

- Correct gripping methods to avoid surface flaws caused by shaking

These problems are even worse when you're working with bars of a bigger width or shapes that are complicated and take longer to cut. Controlling temperature effects by using the right cutting fluid and setting the right parameters makes sure that the material qualities stay the same during the cutting process.

Best Practices for Sawing Monel 401 Bars

When done correctly, sawing is still the most cost-effective way to cut large amounts of material for production. Both band sawing and circle sawing can be used to handle nickel-copper alloys, but different parameters need to be optimized for each to get good results.

Blade Selection and Configuration

If you want to successfully cut something, you need to make sure you choose the right blade setup for the object and job. Compared to regular high-speed steel choices, blades with carbide-tipped teeth work better when working with Monel 401. It is suggested that the teeth be set up with strong rake angles to help chips fall away quickly and lower cutting forces that cause work hardening.

Changeable tooth spacing helps stop harmonic noises that can damage the shine on the blade and make it break too soon. A tooth spacing of 4 to 6 inches per inch usually works best for bars with widths between 25 and 150 mm. For bigger parts, coarser shapes may be better to handle higher chip loads.

Modern blades made of two metals are very flexible and have hard, wear-resistant cutting tips that stay sharp even after a lot of cutting. When used in production settings where quality control and long tool life are important, these blades work especially well when cutting Monel 401 bars.

Cutting Parameters and Cooling Strategies

The cutting quality, tool life, and production effectiveness are all directly affected by the parameters that are chosen correctly. The following tips will help you get the most out of your cutting tasks:

When working with Monel 401, surface speeds of 30 to 50 meters per minute usually strike a good mix between how well the metal cuts and how long the tools last. Feed rates should be changed so that chips are always being made without overworking the cutting edge. Work hardening can be avoided by making sure that aggressive feed rates keep removing material. On the other hand, not enough feed can cause work hardening, which breaks cutting tools quickly.

It is important to use high-quality cutting fluid for flood cooling to control temperature effects and make tools last longer. Water-soluble coolants that are also very good at lubrication help reduce friction while getting rid of heat effectively. The right flow rate and pressure of coolant make sure that the cutting zone is properly cooled and that chips are pushed out of the cut area quickly.

Waterjet Cutting Monel 401 Bars: Advanced Alternatives

When it comes to precise cutting jobs where heat effects must be totally avoided, waterjet cutting technology has a lot to offer. This cold cutting method keeps the metallurgical qualities of Monel 401 stable during the cutting process. This makes it perfect for parts that need to be precisely manufactured and have excellent rust resistance.

Process Fundamentals and Equipment Requirements

High-pressure water (usually 60,000 to 90,000 PSI) and garnet abrasive are used together in abrasive waterjet cutting to remove material in a controlled way. When you cut something with cold steel, there are no heat-affected zones like there are when you use heat to cut something. Because of this, waterjet is especially useful in aircraft and naval uses where the integrity of the materials is very important.

Modern waterjet systems use cutting head and motion control technology that lets them cut complicated shapes with little curve and great edge quality in Monel 401 bar. Cutting along five axes makes it possible to work with complicated shapes that would be hard or impossible to work with with regular saws.

Abrasive Selection and Process Optimization

The choice of garnet grit has a big effect on how well it cuts and how much it costs to run. For most Monel 401 jobs, Mesh 80 garnet strikes a good mix between cutting speed and edge quality. Smaller mesh sizes may be better for precise work that needs a better surface finish. Optimizing the flow rate of an abrasive lowers running costs while keeping cutting speeds that are reasonable.

Monitoring nozzle wear and planning when to change them stops quality loss and unplanned downtime. When focusing tubes get worn out, the beam can shift, which can lead to taper and errors in measurements. Cutting performance stays the same throughout production runs thanks to regular review and aggressive replacement.

Taking care of the water quality by filtering and treating it properly can make parts last longer and keep them cutting well. High-purity water keeps system parts from rusting and stops pollution that can lower the quality of the cutting.

Comparing Cutting Methods: Sawing vs Waterjet Cutting for Monel 401 Bars

To choose the best cutting method, you need to carefully look at the needs of the application, the amount of work that needs to be done, and the quality standards. Cutting with a saw and cutting with a waterjet both have their own benefits that make them good for different situations.

Performance Characteristics Analysis

Sawing works best in places with a lot of output where straight cuts and simple shapes are needed. Quick removal of material and low costs per square inch of cut are two benefits of the process. With the right tools, band sawing can cut bars up to 600 mm in diameter, which makes it good for large-section jobs that are popular in the naval and power generation industries.

Waterjet cutting gives you better edge quality with less finishing work needed and very accurate measurements. The process can easily handle complicated forms and thick pieces, and the quality stays the same no matter how deep the cut goes. Kerf width stays small compared to sawing, which cuts down on waste in expensive metal uses.

Cost-Benefit Evaluation Framework

The amount of production has a big effect on how economically different cutting processes can be compared when cutting Monel 401 bar. Sawing is clearly better for high-volume straight-cutting tasks where the costs of setup can be spread out over a lot of pieces. Saws are good for cutting common materials like Monel 401 bar because they have lower hourly costs and can cut things faster.

When it comes to complicated shapes, precision applications, and modest production numbers, waterjet cutting becomes a good value because the better edge quality removes the need for extra finishing steps. Nesting lets you cut multiple parts at once, which lowers the cost of each part and makes better use of the material.

Cost isn't always taken into account when making a choice; quality standards often are. For aerospace and defense uses, waterjet cutting is often required to get the best material qualities and exact measurements. For marine uses, sawing may be fine for non-critical parts, but waterjets are needed for precise pieces.

Procurement Insights: Sourcing Quality Monel 401 Bars for Cutting Operations

Finding high-quality raw materials that meet strict composition and size standards is the first step to running a successful cutting process. Building relationships with reputable providers guarantees uniform material properties that allow for predictable cutting performance.

Supplier Qualification and Material Standards

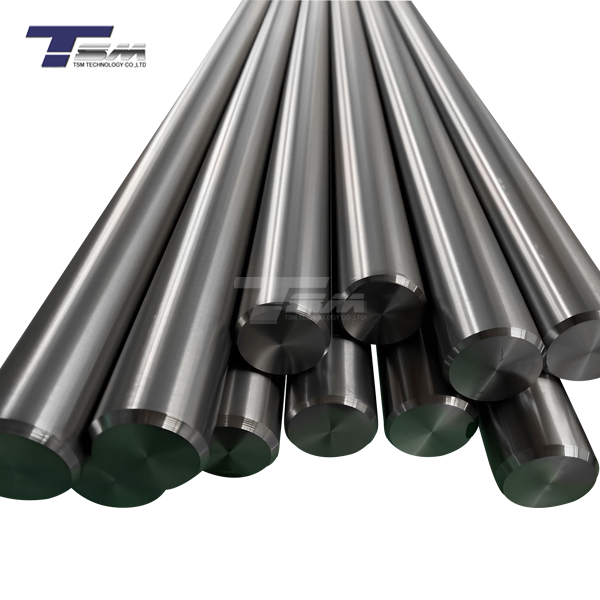

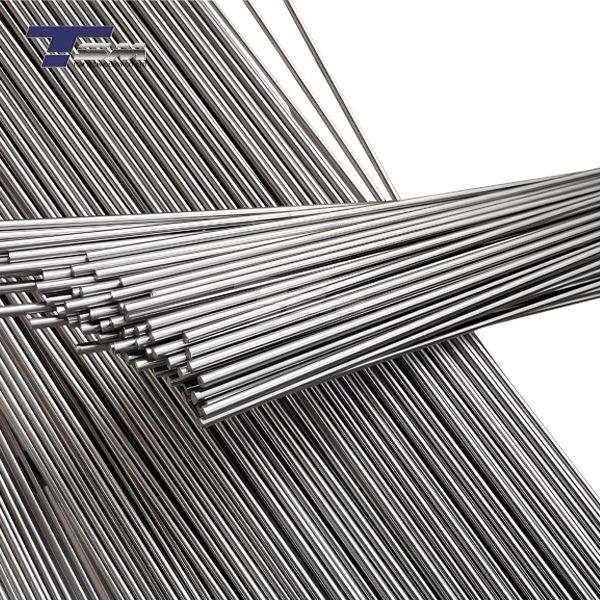

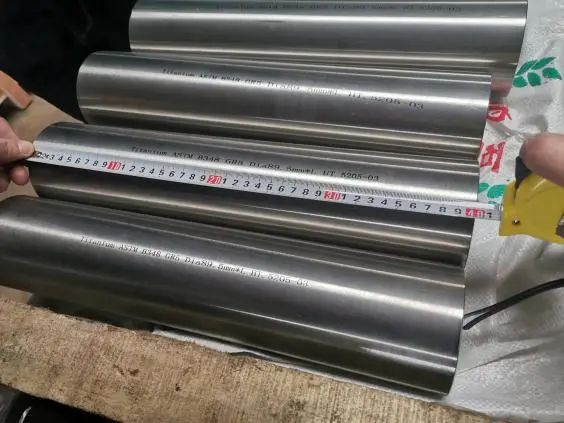

TSM Technology runs three modern manufacturing facilities with more than 100 machines and eight production lines. These facilities can reliably supply 300 tons of Monel 401 bars every month. Our production ranges cover diameters from 5 to 300 mm and lengths from 300 mm to 6000 mm, so we can meet the needs of a wide range of businesses, such as aircraft, marine, and chemical processing.

Material certifications, such as MTC and SGS test records, make it possible to track materials like Monel 401 bar and make sure they are what they say they are for important uses. International standards like ASTM B164, JIS H4551, DIN 17743, and EN 10204 must be followed to make sure that the qualities of the material meet design guidelines and legal requirements.

Custom Solutions and Supply Chain Management

Non-standard sizes and special specs (±0.05mm) meet the needs of specific applications without delaying deliveries. Just-in-time production strategies lower the cost of keeping inventory while keeping production flexible. These strategies use custom length choices and fast shipping options.

Different types of surface finishes, such as turned, peeled, and finished, let you get the most out of the material for different cutting tasks. Surfaces that are properly prepared can extend the life of cutting tools and improve the quality of their edges while lowering the need for extra processing. Cutting trials and process improvement can be done with free samples before placing big orders.

Conclusion

Cutting Monel 401 bar takes careful thought about the material's qualities, the best way to cut it, and how to make the process run as smoothly as possible so that the desired results are achieved while the integrity of the component is maintained. For high-volume straight cutting jobs, sawing is a cheap option. Waterjet cutting, on the other hand, gives you better accuracy and edge quality for tricky shapes and important jobs. Learning about the special features of this nickel-copper metal helps you make smart choices that match performance needs with budget limitations. Choosing the right supplier and getting the right materials are the first steps to getting reliable cutting performance in a wide range of industry settings.

FAQ

1. What cutting speeds work best for Monel 401 bar machining?

For sawing, the best cutting speeds for Monel 401 are usually between 30 and 50 meters per minute, but this depends on the bar thickness and the tools that are used. Lower speeds help control the growth of heat that can harden work, and fast feed rates keep the material removal constant. The speed of a waterjet cutter can be anywhere from 25 to 200 mm per minute, depending on the width and quality of the edge that is wanted.

2. How does Monel 401 compare to Monel 400 for cutting applications?

Monel 401 has a slightly higher nickel content than Monel 400. This makes it more resistant to rust but also makes it more likely to work harden when it is cut. Cutting both metals is pretty much the same, but Monel 401 might benefit from more active cooling methods to keep thermal effects at bay. Since the two metals have similar mechanical properties, cutting parameters that are recommended for one can be used for the other.

3. Can thermal cutting methods be used on Monel 401?

Most of the time, thermal cutting methods like plasma or laser cutting shouldn't be used on Monel 401 because they can create heat-affected zones that can weaken its resistance to rust and mechanical qualities. The high nickel content makes it hard to cut with heat, and the edges are often not very good. For jobs that need exact cuts without thermal effects, waterjet cutting is the best option.

4. What safety measures should be taken when cutting nickel-copper alloys?

Cutting Monel 401 makes metal dust and chips that need to be kept away from people and need proper safety gear. People who are sensitive to nickel dust may have trouble breathing and skin that is easily irritated. The right way to handle and get rid of coolant must be followed to keep the surroundings clean. To keep from getting hurt while cleaning up and getting rid of sharp metal chips, you need to be very careful.

Partner with TSM Technology for Superior Monel 401 Bar Solutions

Expert advice, high-quality products, and reliable supply chain management are just a few of the ways that TSM Technology can help you with your cutting processes. As a trusted Monel 401 bar maker for fourteen years, we can offer custom solutions that make your cutting processes more efficient while ensuring consistent quality and on-time delivery. We can help you get the best results in tough situations by giving you full material certifications, the ability to make unique sizes, and expert support. Email our team at info@tsmnialloy.com to talk about your unique needs and find out how our knowledge can help you improve the quality and speed of your production.

References

1. Davis, J.R. "Nickel, Cobalt, and Their Alloys." ASM Specialty Handbook, ASM International, Materials Park, Ohio, 2000.

2. Rebak, R.B. "Corrosion Performance of Nickel Alloys in Marine Environments." Corrosion Engineering, Science and Technology, Volume 45, Issue 4, 2010.

3. Montero-Ocampo, C. "Machining and Cutting of Nickel-Based Superalloys: A Technical Review." International Journal of Advanced Manufacturing Technology, Volume 67, 2013.

4. Thompson, S.A. "Waterjet Cutting Technology: Applications and Process Optimization for High-Performance Alloys." Manufacturing Engineering Review, Volume 28, Issue 3, 2019.

5. Anderson, K.L. "Heat Treatment and Mechanical Properties of Monel Alloys in Industrial Applications." Materials Science and Engineering Quarterly, Volume 15, 2018.

6. Wilson, P.M. "Procurement Strategies for Specialty Alloys in Aerospace and Marine Industries." Supply Chain Management Journal, Volume 22, Issue 8, 2021.

Learn about our latest products and discounts through SMS or email