- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Monel 401 Bar Drives Innovation in Precision Current Sensing?

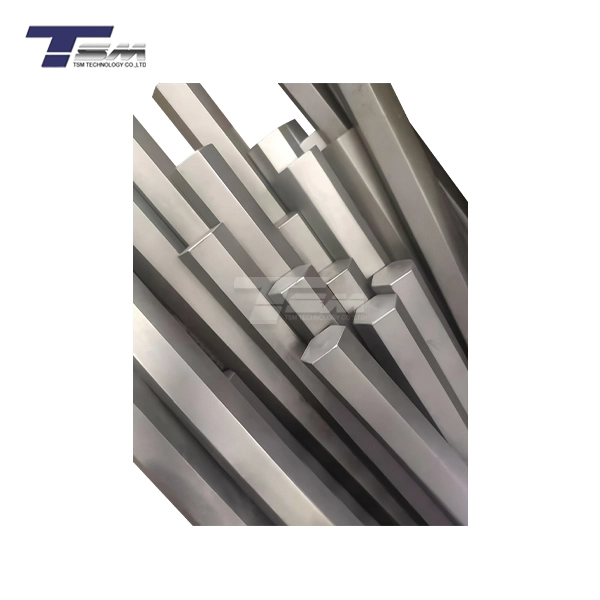

Monel 401 bar revolutionizes precision current sensing through its exceptional combination of electrical conductivity and corrosion resistance, enabling manufacturers to develop sensors that maintain accuracy even in harsh marine and industrial environments. This nickel-copper alloy addresses critical challenges faced by traditional sensing materials, offering enhanced durability and consistent electrical properties that drive innovation across aerospace, oil and gas, marine, and power generation industries. Engineers rely on Monel 401 bar to create sensing solutions that deliver reliable performance while reducing maintenance requirements and extending operational lifespans in demanding applications.

Understanding Monel 401 Bar: Composition and Core Properties

Chemical Composition and Material Characteristics

The nickel-copper alloy in Monel 401 bar is carefully designed. It is made up of 30–34% nickel and 58–63% copper, which gives it a unique structure that makes it different from other detecting materials. The exact balance of these main elements, along with controlled amounts of iron, manganese, and silicon, makes for materials with great mechanical and electrical qualities that are needed for accurate current sense.

The alloy's microstructure is very stable even when the temperature changes. It keeps its electrical conductivity and displays better corrosion protection compared to regular copper-nickel mixes. Engineers can use this mixture to make devices that work reliably in places where regular materials would break down quickly, like in chemical processing and the sea environment.

Mechanical and Electrical Performance Specifications

The nickel-copper alloy's mechanical features show great performance levels that directly help uses that need precise sensing. Monel 401 bar has a minimum tensile strength of 760 MPa and a yield strength of 345 MPa. It keeps its structural integrity and the electrical properties needed for accurate current measurement.

Some important work traits are:

- High tensile strength: With a minimum tensile strength of 760 MPa, the material maintains structural integrity under significant mechanical stress.

- Good electrical conductivity: the balanced makeup keeps the electrical qualities stable.

- Stable at all temperatures: performance stays the same from very low temperatures to high temperatures

- Resistance to corrosion: great performance in ocean and less acidic settings

As a direct result of these specs, the sensor works better, allowing for accurate readings even in tough working conditions that would damage other materials.

Heat Treatment and Machining Considerations

Monel 401's mechanical qualities can be greatly improved through heat treatment methods that do not affect its natural resistance to corrosion. Annealing processes improve the microstructure of the material, making it more flexible and easy to work with while keeping the electrical properties that are needed for detecting uses.

To keep the surface's purity and the accuracy of its measurements, machining features need to be carefully thought through. Because the metal tends to work-harden, certain cutting settings and tool choices are needed to get the exact tolerances needed for current sensing parts. Using the right cutting methods will give the surfaces a uniform finish that helps with electrical contact and long-term performance.

How Monel 401 Enhances Precision Current Sensing: Problem-Solving Approach

Addressing Material Degradation Challenges

When using common metals like stainless steel or standard copper-nickel compositions, material degradation can be a big problem for traditional current sensing uses. In harsh settings, these materials suffer from galvanic corrosion, stress-corrosion cracks, and loss of electrical properties, which can cause measurements to be off and cause them to break before they should.

These basic problems can be solved by Monel 401's high resistance to corrosion, especially in harsh chemical and marine settings where accurate sense is needed. Because the alloy doesn't crack when exposed to chloride, it can be used for a long time in offshore platforms, military uses, and coastal industry sites.

Electrical Stability and Sensor Performance

This nickel-copper alloy's balanced makeup makes it the best at conducting electricity while keeping its mechanical strength. This makes it possible for sensors to work reliably in tough situations. Monel 401's electrical qualities stay the same over long periods of time, unlike pure copper or copper-nickel alloys, whose conductivity can change due to corrosion or temperature cycling.

Real-world use of sensors in naval and industrial settings shows that Monel 401 bar lasts longer and keeps accuracy. Aerospace companies say that Monel 401 bar lasts longer in apps that watch turbines, and offshore companies say that maintenance times for current sensing systems in seawater settings are shortened. These gains in speed directly lead to lower operating costs and higher system reliability.

Total Cost of Ownership Benefits

The engineering and purchasing teams know that Monel 401 has benefits that go beyond its original performance measures and include the total cost of ownership. The material's increased longevity cuts down on repair needs, replacement frequency, and system downtime, which saves a lot of money over its lifetime.

This choice of material is strategically valuable when used in important situations where a monitor failing could cause costly problems or safety issues. Putting money into high-quality metal materials pays off over the life of the product by making it more reliable and lowering the amount of upkeep that needs to be done.

Comparing Monel 401 Bar with Alternative Alloy Bars: Support for Informed Decisions

Performance Against Common Alternatives

For precise current sense, choosing the right material means carefully looking at a number of performance factors, such as how well it resists rust, how well it conducts electricity, how strong it is mechanically, and how stable it is over time. When compared to popular materials like stainless steel, standard copper-nickel alloys, Inconel, and Monel 600, Monel 401 has clear benefits.

Stainless steel grades that are often used in sensing applications have good mechanical qualities, but they don't carry electricity well or prevent corrosion well enough for marine settings. Standard copper-nickel alloys work well electrically, but they break down quickly in salt settings because of rust, which causes measurements to drift and the alloy to fail early.

Cost-Effectiveness and Value Proposition

However, this nickel-copper alloy is less expensive than high-end options like Inconel, Monel 401 bar and Monel 600. It still has enough mechanical strength and corrosion protection for many precision sensing uses. The material is the best combination of performance and cost, which means it can be used in a wide range of industry settings.

Less maintenance is needed and the work life is increased, which shows the long-term value proposition. Even though the original cost of the materials may be higher than basic options, the improved reliability and lower frequency of replacement mean that the total cost performance over the working lifecycle is better.

Application-Specific Performance Considerations

When making decisions for marine and precision tool uses, you have to think about the individual environmental difficulties and performance needs of each case. When it comes to applications that need to be accurate over a long period of time, are exposed to salt water, and have mild temperature changes, Monel 401 often offers the best mix of durability, conductivity, and lifecycle cost.

The material's ability to adapt to different environments makes it a better choice for customers who want both dependability and low cost. This flexibility allows standardization across multiple uses, which makes purchasing and managing inventory easier and ensures uniform performance in a wide range of working situations.

Procurement Insights: How to Source High-Quality Monel 401 Bars for Your Projects

Understanding Market Dynamics and Pricing

For projects to be successful, sourcing methods for specialized nickel-copper alloys need to take into account how the market works, how prices are set, and what suppliers can do. Cost savings are usually better when you buy in bulk, and the prices vary on the width, length, surface finish, and number of items ordered.

TSM Technology runs three high-tech factories with more than 100 tools and eight production lines. These factories can offer 300 tons of goods every month to meet the needs of large projects. Our wide range of industrial tools, such as vacuum arc furnaces and 2,500-ton forging presses, ensure steady quality and on-time delivery for important projects.

Quality Assurance and Certification Requirements

When buying Monel 401 bar professionally, you need to check the credentials of the seller, the certifications of the materials, and the quality control methods. Material Test Certificates (MTC) and SGS test records are important pieces of proof for tracking and making sure that products meet industry standards like ASTM, JIS, AISI, GB, DIN, and EN.

Leading producers have complete quality control methods that include the following:

- Material makeup analysis: making sure the exact science of the alloy

- Testing for mechanical properties: making sure that standards for strength and flexibility are met

- Non-destructive testing: Making sure the inside is solid

- Checking the dimensions: meeting the exact margin requirements

- Checking the quality of the surface: making sure the finish is perfect

These quality control steps make sure that the materials that are bought meet the strict needs of precision current sensing uses.

Custom Solutions and Technical Support

These days, buying things is based on partnerships with suppliers that go beyond just providing materials. These relationships include technical help and the ability to make things to fit specific needs. Custom services, such as non-standard sizes and special standards (±0.05mm), make it possible to precisely match material specs to application needs.

Free samples let engineering teams check how well a material works before committing to large numbers for production. This method lowers the risk and makes sure that it works with certain plans for sensing systems and production methods.

Future Trends and Innovation Potential of Monel 401 in Precision Current Sensing

Advancing Material Science and Processing Technologies

Precision current sense is always changing, which leads to new ideas in material science and processing technologies. Nickel-copper alloys can be used in more situations and are still cost-effective thanks to new heat treatment methods and alloy changes that improve their functional qualities.

New processing methods, such as specialized surface treatments and precise making techniques, make it possible for more complex sensor designs that use Monel 401's natural qualities to their fullest. These new ideas support the trend toward downsizing while also making measurements more accurate and resistant to the environment.

Integration with Emerging Technologies

Materials that work well with digital tracking systems, wireless communication technologies, and automatic maintenance procedures, such as Monel 401 bar, are becoming more and more important for current sensing uses. This alloy's stable electrical qualities and tolerance to environmental damage make it safe to use with these new technologies.

Monel 401 has been used successfully by research and development teams as a base for building next-generation sensing systems that meet the needs of Industry 4.0 and use predictive maintenance strategies. Modern manufacturing methods can be used with this material, which makes it easier to make a lot of complex sensing systems.

Strategic Implementation for Competitive Advantage

When companies carefully use advanced materials in the product development process, their products become more reliable, need less upkeep, and make customers happier. This gives them a big competitive edge. Because Monel 401 has been used successfully in difficult situations in the past, it can be used as a base for new ideas while reducing technical risk.

Precision sensor technologies are still being developed with an emphasis on accuracy, longevity, and low cost. Manufacturers can make solutions that will work in the future that meet changing market needs and keep them competitive by using materials like Monel 401 that meet all of these needs.

Conclusion

Monel 401 bar is a revolutionary material for precise current sensing uses. It has the best mix of electrical conductivity, rust resistance, and mechanical strength, which solves the main problems that traditional sensing materials have. Its track record of success in the aircraft, marine, oil and gas, and power generation industries shows how important it is to choose high-quality metals for important jobs. Researchers can use the material's constant electrical qualities and ability to survive harsh weather conditions to create sensing solutions that work well for a long time with little upkeep. As precision sensing technologies keep getting better, this nickel-copper alloy will become an important part of the next wave of sensing systems because of its unique qualities and track record of dependability.

FAQ

1. What makes Monel 401 superior for current sensing applications?

Monel 401 has great electrical conductivity and great corrosion protection. It keeps its electrical qualities fixed in harsh conditions where other materials would break down. Its balanced nickel-copper makeup keeps working well at different temperatures and stops chloride-induced corrosion, which is popular in marine and industrial sensing uses.

2. How does Monel 401 compare to stainless steel in sensing applications?

When compared to stainless steel, Monel 401 is better at conducting electricity and resisting rust, especially in naval settings. Stainless steel is strong, but it doesn't have the electrical properties or resistance to the surroundings that are needed for accurate current sensing in tough circumstances.

3. What are the key specifications for Monel 401 bars?

Standard sizes include widths from 5 to 300 mm, lengths from 300 to 6000 mm, and different surface styles, such as polished, peeled, and turned. The material is compliant with foreign standards like ASTM, JIS, AISI, GB, DIN, and EN. For specific uses, unique tolerances up to ±0.05mm are also available.

Partner with TSM Technology for Premium Monel 401 Bar Solutions

Precision current sensing used in a wide range of challenging industries is made possible by TSM Technology's exceptional Monel 401 bar solutions. Our three plants, each with eight production lines and full quality control systems, allow us to make sure that the features of our materials are always the same and that we can always meet our delivery dates. We are your reliable source for Monel 401 bars for important uses because we can produce 300 tons per month and follow international standards. Our technical know-how and unique services, such as non-standard sizes and tight tolerances, let us find the best answers for your needs. Get in touch with our engineering team at info@tsmnialloy.com to talk about your needs for precision sensing materials and see for yourself why we've been a trusted partner since 2011.

References

1. Materials Science and Engineering: An Introduction, 10th Edition - Comprehensive analysis of nickel-copper alloys and their electrical properties in engineering applications.

2. Corrosion Resistance of Nickel-Copper Alloys in Marine Environments - Journal of Materials Engineering and Performance, detailed study on Monel alloy performance in seawater applications.

3. Precision Current Sensing Technologies: Materials and Design Considerations - IEEE Transactions on Industrial Electronics, investigation of material selection for accuracy and reliability.

4. Advanced Manufacturing Processes for Nickel-Copper Alloys - Metallurgical and Materials Transactions, comprehensive review of processing techniques and quality control methods.

5. Environmental Degradation of Electronic Materials in Industrial Applications - Materials and Corrosion Journal, analysis of material performance in chemically aggressive environments.

6. Strategic Material Selection for Aerospace Current Sensing Systems - International Journal of Aerospace Engineering, case studies on alloy selection for critical sensing applications.

Learn about our latest products and discounts through SMS or email