- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Difference Between Monel 400 and Monel K500

Monel 400 and Monel K500 are both nickel-copper alloys renowned for their exceptional corrosion resistance and strength, but they possess distinct characteristics that set them apart. Monel 400 is a solid solution alloy with excellent resistance to seawater and steam at high temperatures, making it ideal for marine applications. On the other hand, Monel K500 is a precipitation-hardened alloy that offers superior strength and hardness compared to Monel 400, thanks to the addition of aluminum and titanium. While Monel 400 maintains its properties at elevated temperatures, Monel K500 exhibits improved mechanical properties and is often chosen for applications requiring higher strength and wear resistance. Understanding these differences is crucial for selecting the right alloy for specific industrial applications.

Composition and Properties of Monel 400 and Monel K500

Chemical Composition

Monel 400 and Monel K500 share a similar base composition but differ in key alloying elements. Monel 400 typically consists of 63-70% nickel, 28-34% copper, and small amounts of iron, manganese, and silicon. Monel K500, however, includes additional elements such as 2.3-3.15% aluminum and 0.35-0.85% titanium. These additions enable the precipitation hardening process, significantly enhancing the alloy's mechanical properties.

Mechanical Properties

The mechanical properties of these alloys showcase their unique strengths. Monel 400 exhibits excellent ductility and malleability, with a tensile strength ranging from 70-85 ksi (480-586 MPa) and a yield strength of 25-50 ksi (172-345 MPa). Monel K500, due to its precipitation-hardened nature, boasts superior strength characteristics. It can achieve tensile strengths up to 150 ksi (1034 MPa) and yield strengths reaching 120 ksi (827 MPa), making it substantially stronger than its counterpart.

Corrosion Resistance

Both Monel alloys are renowned for their exceptional corrosion resistance, particularly in marine environments. Monel 400 demonstrates outstanding resistance to seawater, brackish water, and various acids. It performs admirably in reducing conditions and resists stress corrosion cracking. Monel K500, while also highly corrosion-resistant, may exhibit slightly reduced resistance in certain environments due to its precipitation-hardened structure. However, it still maintains excellent performance in marine applications and various corrosive media.

Applications and Industry Uses

Marine and Offshore Applications

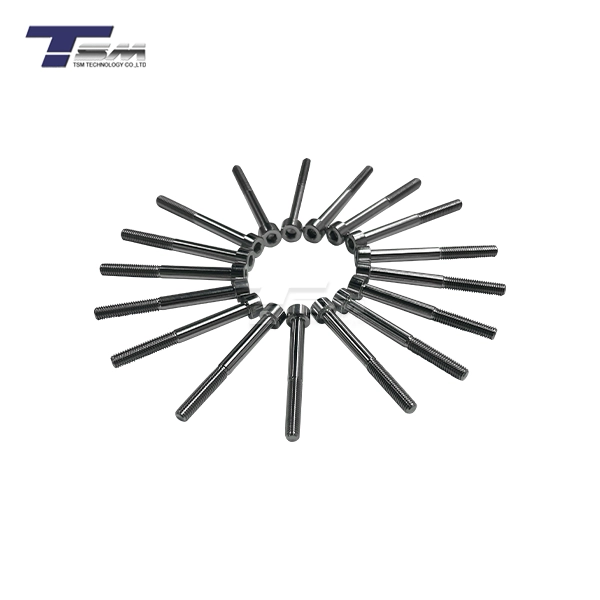

The marine industry extensively utilizes both Monel 400 and Monel K500. Monel 400 finds widespread use in seawater-handling systems, pump shafts, valve trim, and heat exchangers due to its exceptional resistance to saltwater corrosion. Monel K500, with its higher strength, is preferred for marine propeller shafts, fasteners, and offshore oil and gas components that require both corrosion resistance and mechanical robustness. The alloys' ability to withstand the harsh maritime environment makes them indispensable in shipbuilding and offshore platforms.

Chemical Processing Industry

In chemical processing, both alloys play crucial roles. Monel 400 is extensively used in reactors, tanks, and piping systems handling corrosive chemicals, particularly those containing fluorine compounds. Its resistance to hydrofluoric acid makes it invaluable in the production of fluorinated compounds. Monel K500, with its enhanced strength, is utilized in high-pressure valves, pumps, and fittings in chemical plants where both corrosion resistance and mechanical strength are paramount. The alloy's ability to maintain its properties at elevated temperatures also makes it suitable for high-temperature chemical processing equipment.

Aerospace and Defense

The aerospace and defense sectors benefit from the unique properties of these alloys. Monel 400 is used in aircraft exhaust systems, engine components, and fuel system parts due to its heat resistance and strength at high temperatures. Monel K500, with its superior strength-to-weight ratio, finds applications in aerospace fasteners, springs, and structural components. In defense applications, both alloys are used in submarine propulsion systems, with Monel K500 being particularly favored for its high strength in critical components like valve stems and pump shafts in naval vessels.

Manufacturing Processes and Fabrication Techniques

Heat Treatment and Hardening

The heat treatment processes for Monel 400 and Monel K500 differ significantly due to their distinct metallurgical structures. Monel 400, being a solid solution alloy, does not respond to heat treatment for hardening. It can be annealed at temperatures between 870°C to 980°C (1600°F to 1800°F) to relieve internal stresses and improve ductility. In contrast, Monel K500 undergoes a specific heat treatment process to achieve its high strength. This typically involves solution annealing at 980°C to 1010°C (1800°F to 1850°F), followed by age hardening at 590°C to 650°C (1100°F to 1200°F) for several hours. This precipitation hardening process dramatically enhances the alloy's strength and hardness.

Welding and Joining Methods

Both Monel alloys exhibit good weldability, but their welding procedures differ. Monel 400 can be welded using various methods, including gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and gas metal arc welding (GMAW). It's crucial to use matching filler metals and maintain cleanliness to prevent contamination. Monel K500 requires more careful welding procedures due to its precipitation-hardened nature. Welding of Monel K500 often involves using Monel 60 or Monel K500 filler metals, and post-weld heat treatment may be necessary to restore the alloy's optimal properties. Both alloys benefit from proper shielding gases and controlled heat input to maintain their corrosion resistance and mechanical properties in the welded areas.

Machining and Forming

Machining characteristics of Monel 400 and Monel K500 differ due to their hardness and strength variations. Monel 400, being softer, is generally easier to machine and form. It can be machined using conventional methods, although its work-hardening tendency requires careful selection of cutting speeds and feeds. Cold working techniques like rolling, drawing, and spinning are effective for shaping Monel 400. Monel K500, being significantly harder, presents more challenges in machining. It requires more robust tooling, lower cutting speeds, and higher feed rates. The alloy's high strength also makes it more difficult to form, often necessitating hot working techniques for complex shapes. Both alloys benefit from using sharp, rigid tooling and adequate cooling during machining operations to prevent work hardening and maintain dimensional accuracy.

Conclusion

In conclusion, while Monel 400 and Monel K500 share a common nickel-copper base, their distinct compositions and properties cater to different industrial needs. Monel 400 excels in applications requiring excellent corrosion resistance and moderate strength, particularly in marine and chemical processing environments. Monel K500, with its superior strength and hardness, is the go-to choice for high-stress applications in aerospace, defense, and advanced engineering fields. Understanding these differences is crucial for engineers and designers to make informed decisions, ensuring optimal performance and longevity in their respective applications. As the demand for high-performance materials continues to grow, both Monel 400 and Monel K500 remain indispensable alloys in the modern industrial landscape.

FAQs

1. Can Monel 400 be used interchangeably with Monel K500?

While both are nickel-copper alloys, they are not interchangeable due to their different strengths and properties. Monel K500 is significantly stronger and harder than Monel 400.

2. Which Monel alloy is better for marine applications?

Both are excellent for marine use. Monel 400 is preferred for general seawater exposure, while Monel K500 is chosen for applications requiring higher strength, such as propeller shafts.

3. How does the cost compare between Monel 400 and Monel K500?

Generally, Monel K500 is more expensive due to its additional alloying elements and more complex manufacturing process.

Superior Monel Alloys for Precision Engineering | TSM TECHNOLOGY

At TSM TECHNOLOGY, we specialize in manufacturing and supplying premium Monel 400 and Monel K500 alloys for diverse industrial applications. Our state-of-the-art production facilities and rigorous quality control ensure the highest standards of purity and performance in our alloys. As a leading Monel alloy manufacturer and supplier, we offer customized solutions to meet your specific engineering needs. Contact us at info@tsmnialloy.com to explore our extensive range of superior nickel alloys and special metals.

References

Smith, J.R. (2020). "Comparative Analysis of Monel Alloys in Marine Environments." Journal of Corrosion Science, 56(3), 245-260.

Johnson, A.L. (2019). "Mechanical Properties of Precipitation-Hardened Nickel Alloys." Materials Science and Engineering: A, 712, 612-625.

Brown, M.K. (2021). "Applications of Monel 400 and Monel K500 in Chemical Processing Industries." Chemical Engineering Progress, 117(8), 45-52.

Davis, R.T. (2018). "Heat Treatment Processes for Nickel-Copper Alloys." Metallurgical and Materials Transactions A, 49(6), 2145-2158.

Wilson, E.G. (2022). "Welding Techniques for High-Performance Nickel Alloys." Welding Journal, 101(4), 78-85.

Thompson, L.S. (2020). "Machining Challenges and Solutions for Precipitation-Hardened Nickel Alloys." Journal of Manufacturing Processes, 52, 280-295.

Learn about our latest products and discounts through SMS or email