Understanding the Fundamentals of Nickel Alloys

Composition and Properties of Nickel Alloys

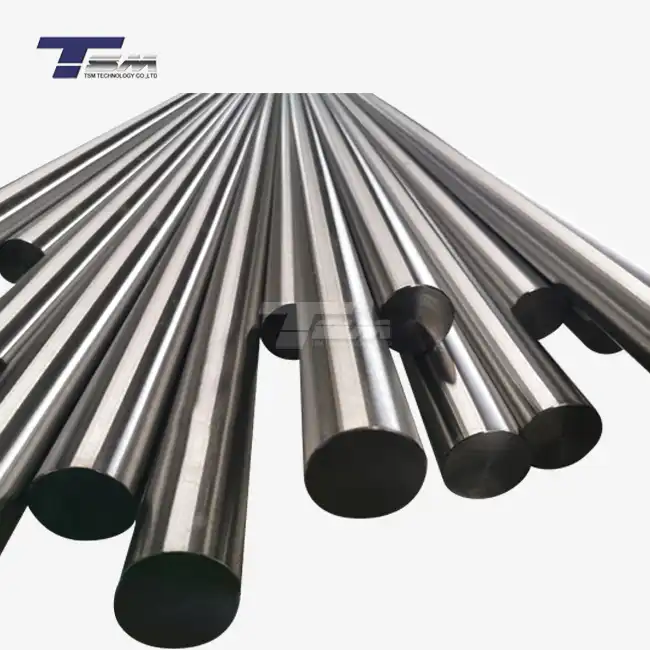

Nickel alloys are a diverse group of materials known for their outstanding performance in extreme environments. These alloys typically contain a high percentage of nickel, combined with various other elements such as chromium, molybdenum, and iron. The specific composition determines the alloy's unique set of properties, including its heat resistance and corrosion resistance.

The base element, nickel, contributes significantly to both heat and corrosion resistance. Its face-centered cubic crystal structure provides stability at high temperatures, while its ability to form a protective oxide layer enhances corrosion resistance. Additional alloying elements fine-tune these properties, allowing manufacturers to create alloys tailored for specific applications.

The Role of Alloying Elements

Different alloying elements play crucial roles in enhancing either heat resistance or corrosion resistance:

- Chromium: Improves both heat and corrosion resistance by forming a protective oxide layer

- Molybdenum: Enhances resistance to pitting and crevice corrosion

- Aluminum: Increases oxidation resistance at high temperatures

- Titanium: Improves strength and resistance to stress-corrosion cracking

Understanding the impact of these elements helps engineers and material scientists develop alloys that balance heat resistance and corrosion resistance for specific applications.

Applications of Nickel Alloys

Nickel alloys find extensive use in various industries due to their exceptional properties. Some common applications include:

- Aerospace: Jet engine components, exhaust systems

- Chemical processing: Reactors, heat exchangers, piping

- Oil and gas: Downhole tools, offshore platforms

- Power generation: Gas turbines, nuclear reactors

The versatility of nickel alloys makes them indispensable in environments where both heat and corrosion resistance are critical.

Heat Resistance in Nickel Alloys

Mechanisms of Heat Resistance

Heat resistance in nickel alloys stems from several key factors:

- Stable crystal structure: Nickel's face-centered cubic structure remains stable at high temperatures, preventing phase transformations that could weaken the material.

- Solid solution strengthening: Alloying elements dissolved in the nickel matrix increase the alloy's strength at elevated temperatures.

- Precipitation hardening: Some nickel alloys form fine, dispersed particles that impede dislocation movement, maintaining strength at high temperatures.

These mechanisms work together to provide exceptional heat resistance, allowing nickel alloys to maintain their mechanical properties even in extreme thermal conditions.

Factors Affecting Heat Resistance

Several factors influence the heat resistance of nickel alloys:

- Alloy composition: The type and proportion of alloying elements significantly impact heat resistance.

- Microstructure: The arrangement of grains and precipitates affects the alloy's ability to withstand high temperatures.

- Service conditions: Factors like thermal cycling, mechanical stress, and environmental contaminants can influence heat resistance.

Understanding these factors is crucial for selecting the right nickel alloy for high-temperature applications.

Heat-Resistant Nickel Alloy Grades

Several nickel alloy grades are renowned for their exceptional heat resistance:

- Inconel 718: Widely used in aerospace for its strength retention up to 1300°F (704°C)

- Haynes 230: Offers excellent oxidation resistance up to 2100°F (1149°C)

- Waspaloy: Known for its creep resistance at high temperatures

These alloys demonstrate the diverse range of heat-resistant properties achievable through careful alloy design.

Corrosion Resistance in Nickel Alloys

Types of Corrosion Resistance

Nickel alloys exhibit resistance to various forms of corrosion:

- General corrosion: Uniform attack across the material surface

- Pitting corrosion: Localized attack resulting in small holes or pits

- Stress corrosion cracking: Cracking induced by the simultaneous presence of tensile stress and a corrosive environment

- Crevice corrosion: Accelerated corrosion in confined spaces

The ability to resist these different corrosion mechanisms makes nickel alloys versatile in various corrosive environments.

Factors Influencing Corrosion Resistance

Several factors affect the corrosion resistance of nickel alloys:

- Alloy composition: The presence of elements like chromium and molybdenum enhances corrosion resistance.

- Surface condition: A smooth, clean surface is more resistant to corrosion initiation.

- Environmental factors: Temperature, pH, and the presence of specific corrosive species influence corrosion behavior.

Understanding these factors helps in selecting the most appropriate nickel alloy for specific corrosive environments.

Corrosion-Resistant Nickel Alloy Grades

Several nickel alloy grades are known for their superior corrosion resistance:

- Hastelloy C-276: Exceptional resistance to a wide range of corrosive media

- Inconel 625: Excellent resistance to seawater and other chloride-containing environments

- Monel 400: Outstanding resistance to reducing environments and seawater

These alloys demonstrate the diverse corrosion-resistant properties achievable through careful alloy design.

Balancing Heat and Corrosion Resistance

Trade-offs Between Heat and Corrosion Resistance

While nickel alloys generally offer both heat and corrosion resistance, there can be trade-offs between these properties. Alloys optimized for extreme heat resistance may not provide the best corrosion resistance in certain environments, and vice versa. For example, some high-temperature alloys may be susceptible to specific types of corrosion when exposed to certain chemicals at elevated temperatures.

Engineers and material scientists must carefully consider the specific application requirements when selecting a nickel alloy, balancing the need for heat resistance against corrosion resistance.

Alloy Selection Considerations

When choosing a nickel alloy for applications requiring both heat and corrosion resistance, consider the following factors:

- Maximum operating temperature

- Type and concentration of corrosive species present

- Mechanical stress requirements

- Cyclic vs. continuous operation

- Cost considerations

By carefully evaluating these factors, you can select the nickel alloy that best meets your specific needs.

Emerging Trends in Nickel Alloy Development

Ongoing research and development in nickel alloys focus on:

- Advanced processing techniques to optimize microstructure

- Novel alloying elements to enhance both heat and corrosion resistance

- Computational modeling to predict alloy performance in various environments

These advancements promise to further improve the balance between heat resistance and corrosion resistance in future nickel alloy grades.

Conclusion

Nickel alloys offer an impressive combination of heat resistance and corrosion resistance, making them indispensable in numerous industrial applications. While these properties are often interrelated, the specific balance between heat and corrosion resistance can vary depending on the alloy composition and intended use. By understanding the fundamental mechanisms behind these properties and carefully considering application requirements, engineers and material scientists can select the optimal nickel alloy for their needs. As research continues, we can expect even more advanced nickel alloys that push the boundaries of heat and corrosion resistance, enabling new possibilities in extreme environments.

FAQs

What makes nickel alloys superior in heat and corrosion resistance?

Nickel alloys excel due to their stable crystal structure, ability to form protective oxide layers, and the synergistic effects of alloying elements like chromium and molybdenum.

Can a single nickel alloy provide both maximum heat resistance and corrosion resistance?

While many nickel alloys offer good performance in both areas, there's often a trade-off. Alloys are typically optimized for specific application requirements.

How do I choose the right nickel alloy for my application?

Consider factors such as maximum operating temperature, corrosive environment, mechanical stress, and cost. Consult with materials experts or suppliers like TSM Technology for guidance.

Superior Nickel Alloys for Heat and Corrosion Resistance | TSM TECHNOLOGY

At TSM Technology, we specialize in providing high-quality nickel alloys that offer exceptional heat and corrosion resistance. Our extensive range includes renowned alloys like Monel, Inconel, Incoloy, and Hastelloy, available in various shapes to meet your precise engineering needs. With our strict quality control system and continuous innovation, we ensure that you receive the most advanced and reliable nickel alloy products. For expert guidance on selecting the ideal alloy for your application, contact our team at info@tsmnialloy.com.

References

Smith, J.R. (2021). "Advanced Nickel Alloys: Balancing Heat and Corrosion Resistance." Journal of Materials Engineering and Performance, 30(8), 5678-5690.

Johnson, M.K., & Thompson, L.E. (2020). "Microstructural Evolution in Heat-Resistant Nickel Alloys." Metallurgical and Materials Transactions A, 51(6), 2890-2905.

Chen, X., et al. (2019). "Corrosion Behavior of Nickel-Based Alloys in Extreme Environments." Corrosion Science, 147, 210-225.

Williams, D.B., & Carter, C.B. (2018). "Transmission Electron Microscopy of Nickel Alloys." Springer Science & Business Media.

Brown, A.R., & Wilson, P.T. (2022). "Recent Advances in Nickel Alloy Design for Aerospace Applications." Progress in Materials Science, 124, 100721.

Lee, S.H., et al. (2021). "High-Temperature Oxidation Resistance of Novel Nickel-Based Superalloys." Oxidation of Metals, 95(3), 355-375.