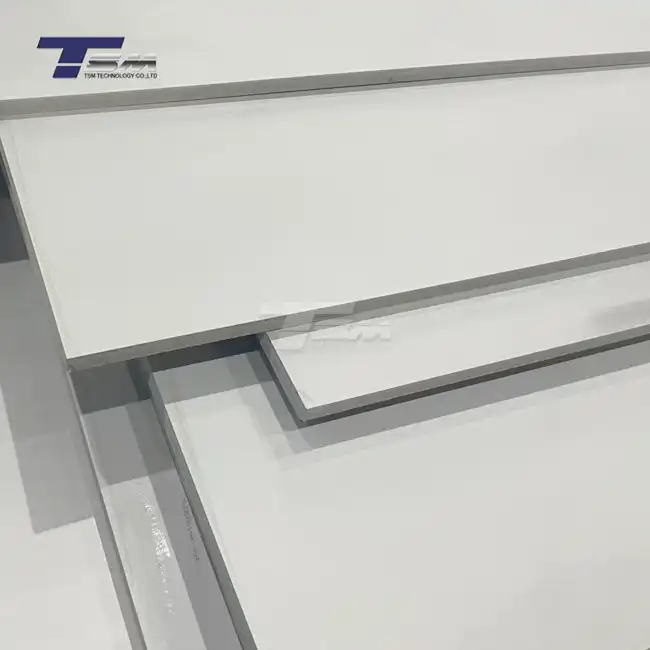

Chemical Composition and Physical Properties of Nickel 201 Sheet

Chemical Makeup: The Foundation of Nickel 201's Performance

Nickel 201 sheet boasts a chemical composition that sets it apart from other nickel alloys. With a minimum nickel content of 99.0%, this alloy offers unparalleled purity. The remaining constituents, carefully controlled during manufacturing, include trace amounts of carbon, manganese, iron, sulfur, silicon, and copper. This precise balance of elements contributes to the material's exceptional properties, making it ideal for applications requiring high corrosion resistance and thermal stability.

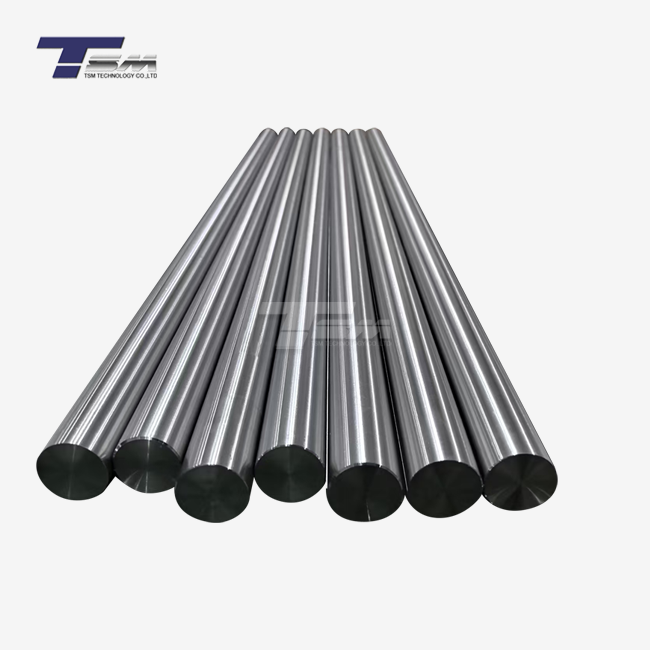

Density and Melting Point: Key Physical Attributes

The density of Nickel 201 plate is approximately 8.89 g/cm³, providing an excellent strength-to-weight ratio. This characteristic makes it suitable for applications where weight considerations are crucial, such as in aerospace components. The melting point of Nickel 201 ranges between 1435°C to 1446°C (2615°F to 2635°F), allowing it to maintain its structural integrity in high-temperature environments. These physical properties contribute to the alloy's versatility across various industrial applications.

Thermal and Electrical Conductivity: Enhancing Performance

Nickel 201 sheet exhibits impressive thermal conductivity, making it an excellent choice for heat exchange applications. Its thermal expansion coefficient is relatively low, ensuring dimensional stability across a wide temperature range. Additionally, the electrical resistivity of Nickel 201 is approximately 9.5 μΩ·cm at 20°C, providing good electrical conductivity when required. These properties make Nickel 201 an ideal material for components in electrical and thermal management systems.

Mechanical Properties and Strength Characteristics

Tensile Strength and Yield Strength: Ensuring Structural Integrity

The mechanical properties of Nickel 201 sheet are impressive, contributing to its reliability in demanding applications. In its annealed condition, Nickel 201 typically exhibits a tensile strength ranging from 380 to 550 MPa (55 to 80 ksi). The yield strength, a critical parameter for design engineers, usually falls between 105 to 195 MPa (15 to 28 ksi). These values can vary slightly depending on the specific heat treatment and cold working processes applied during manufacturing.

Elongation and Hardness: Balancing Ductility and Durability

Nickel 201 plate demonstrates excellent ductility, with elongation values typically ranging from 35% to 55% in a 2-inch gauge length. This high elongation allows for significant plastic deformation before failure, making the material suitable for forming operations and applications requiring good toughness. The Rockwell B hardness of annealed Nickel 201 usually falls between 45 to 75, providing a good balance between malleability and wear resistance.

Impact Strength and Fatigue Resistance: Long-Term Performance

The impact strength of Nickel 201 sheet is noteworthy, especially at cryogenic temperatures, where it maintains its toughness. This property makes it suitable for low-temperature applications. Fatigue resistance is another crucial characteristic, with Nickel 201 demonstrating good performance under cyclic loading conditions. The material's ability to withstand repeated stress without failure contributes to its longevity in dynamic environments, such as those found in turbine components or chemical processing equipment.

Corrosion Resistance and Environmental Performance

Resistance to Acidic and Alkaline Environments

One of the standout features of Nickel 201 sheet is its exceptional corrosion resistance across a wide range of chemical environments. In acidic conditions, particularly those involving non-oxidizing acids like hydrochloric acid, Nickel 201 exhibits superior resistance compared to many other metals and alloys. Its performance in alkaline environments is equally impressive, making it a preferred choice for caustic soda handling and production facilities. This broad-spectrum corrosion resistance significantly extends the lifespan of components made from Nickel 201, reducing maintenance costs and improving overall system reliability.

High-Temperature Oxidation Behavior

Nickel 201 sheet demonstrates excellent resistance to high-temperature oxidation, a critical property for applications involving elevated temperatures. The formation of a stable, adherent oxide layer on the surface of Nickel 201 protects against further oxidation, even at temperatures exceeding 1000°C (1832°F). This characteristic makes Nickel 201 an ideal material for heat-treating equipment, furnace components, and other high-temperature processing applications where maintaining structural integrity is paramount.

Stress Corrosion Cracking Resistance

Stress corrosion cracking (SCC) is a significant concern in many industrial applications, particularly those involving corrosive environments combined with tensile stresses. Nickel 201 sheet exhibits remarkable resistance to SCC in various media, including chloride-containing environments that are notorious for causing this type of failure in many other materials. This resistance to SCC enhances the reliability and safety of components made from Nickel 201, particularly in critical applications such as chemical processing equipment, heat exchangers, and pressure vessels.

Conclusion

Exploring the key specifications of Nickel 201 sheet reveals a material of exceptional quality and versatility. Its unique combination of high purity, excellent corrosion resistance, and impressive mechanical properties makes it an invaluable asset in numerous industrial applications. From its superior performance in caustic environments to its ability to maintain structural integrity at high temperatures, Nickel 201 continues to be a preferred choice for engineers and manufacturers facing challenging material requirements. As industries evolve and demand ever-higher performance standards, a comprehensive understanding of Nickel 201's specifications becomes increasingly crucial for informed decision-making and innovative design solutions.

Contact Us

For more information about Nickel 201 sheet and plate, or to discuss how this exceptional material can benefit your specific application, please don't hesitate to contact us at info@tsm-technology.com. Our team of experts is ready to assist you in selecting the right material for your project needs.